The Programmable Logic Controller (PLC) is a critical component of a die casting machine, responsible for controlling various automated processes.

Maintenance points for die casting machine PLC

Proper maintenance ensures the machine’s reliability, longevity, and efficiency. Below are the key maintenance points for a die-casting machine PLC:

Regular Inspection & Cleaning

Dust & Debris Removal: Clean the PLC cabinet and surrounding area to prevent overheating and electrical faults.

Check Ventilation & Cooling: Ensure cooling fans and heat sinks are functioning properly.

Inspect Wiring & Connections: Look for loose, corroded, or damaged wires and terminals.

Power Supply Check

Voltage Stability: Verify that the input power supply matches the PLC’s requirements (typically 24V DC or 110V/220V AC).

UPS/Battery Backup: Ensure backup power systems (if any) are operational to prevent data loss during power fluctuations.

Grounding: Confirm proper grounding to avoid electrical noise interference.

PLC Program & Memory Backup

Regular Backups: Save the PLC program and parameters periodically to prevent data loss.

Check for Corruption: Monitor for unexpected program changes or faults.

Firmware Updates: Apply manufacturer-recommended updates if necessary.

Input/Output (I/O) Module Maintenance

Inspect Sensors & Actuators: Ensure proximity switches, pressure sensors, and limit switches are functioning correctly.

Test Digital & Analog I/Os: Verify signal accuracy and responsiveness.

Replace Faulty Modules: Swap out malfunctioning I/O modules promptly.

Communication & Networking

Check Communication Cables (RS-485, Ethernet, Profibus, etc.): Ensure no physical damage or loose connections.

Monitor Network Stability: Look for communication errors or delays in HMI/SCADA interactions.

Test Remote Access (if applicable): Ensure secure and stable connectivity.

Environmental Protection

Temperature & Humidity Control: Maintain ambient conditions within the PLC’s operating range.

Protect from Oil & Moisture: Seal the PLC cabinet to prevent oil ingress (common in die-casting environments).

Vibration Resistance: Secure mounting to minimize vibrations affecting components.

Error Logging & Diagnostics

Monitor PLC Alarms: Regularly check for fault codes or warnings in the HMI.

Analyze Historical Data: Review logs to identify recurring issues.

Reset & Clear Faults: Address errors promptly to avoid cascading failures.

Preventive Replacement of Critical Components

Relays & Contactors: Replace worn-out components before failure.

Backup Battery (for RAM storage): Change every 2-5 years to retain memory.

Capacitors & Power Modules: Inspect for bulging or leakage.

Operator & Technician Training

Proper Handling: Train staff to avoid accidental parameter changes.

Emergency Procedures: Ensure correct shutdown/restart protocols.

Troubleshooting Skills: Familiarize maintenance teams with common PLC issues.

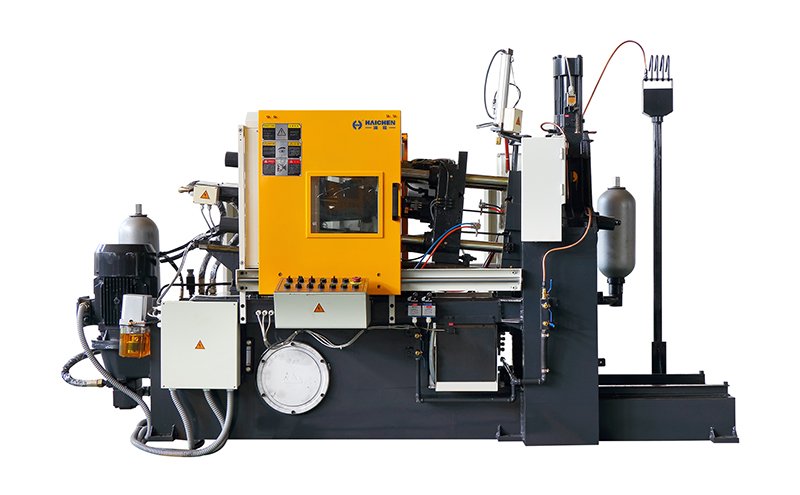

Die casting machine PLC supplier: Haichen Machinery

Haichen Machinery is a Chinese company specializing in die casting machines and peripheral equipment, including PLC control systems for die casting automation.

We provide integrated solutions for pressure die casting (aluminum, zinc, magnesium) with a focus on energy efficiency and precision control.

Key Features of Haichen Die Casting Machines with PLC Control:

Automation & Control Capabilities:

- Real-time monitoring of injection pressure, speed, and temperature.

- Closed-loop control for high-pressure die casting (HPDC).

- Integration with robots, extractors, and spraying systems.

Machine Range:

- Cold chamber die casting machines (for aluminum/magnesium).

- Hot chamber machines (for zinc alloys).

- Servo-driven models for energy savings.

After-Sales & Support:

- Provides PLC programming, maintenance, and troubleshooting services.

- Customizable PLC logic for specific production needs.