Understanding the Manufacturing process of cast aluminum cookware is essential for producing high – quality and durable kitchenware.

Cast aluminum cookware holds a major place in the global market because it conducts heat well, is durable, and affordable.

A strict manufacturing process is key to making products that heat evenly, last long, and are safe to use. Precision control at every step, from melting the metal to final checks, directly affects the quality and performance of the finished product.

This article explains the key steps in making cast aluminum cookware and the vital role of professional equipment.

Manufacturing process of cast aluminum cookware

- Material Preparation

- Mold Design and Preparation

- Casting Process

- Cooling and Solidification

- Post – Casting Processing

- Assembly and Packaging

Material Preparation

The first step in manufacturing cast aluminum cookware is the preparation of the aluminum alloy. Manufacturers blend high-purity aluminum with precise amounts of silicon, copper and other metals to boost strength and durability. Materials engineers carefully formulate these alloys to optimize casting performance.

Mold Design and Preparation

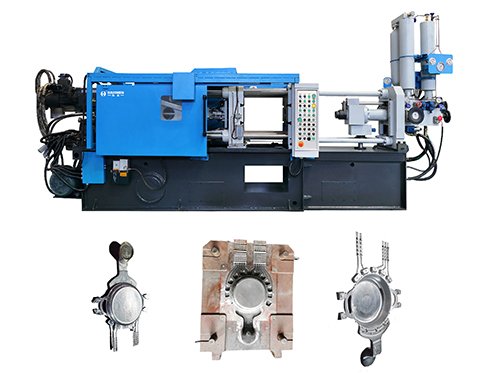

The design of the mold is crucial for the final shape and quality of the cookware. HAICHEN’s engineers design precision molds to form all cookware components, including pots, pans, and lids. They construct these molds from high-strength steel to endure extreme casting temperatures and pressures. Our advanced design team customizes each mold to exact cookware specifications.

Casting Process

The casting process begins with melting the aluminum alloy in a furnace. Workers pour the molten aluminum into prepared molds. In die casting, high-pressure injection systems force the molten metal into the mold cavity, achieving precise and uniform filling. HAICHEN’s die casting machines deliver consistent, high-quality castings that minimize defects and maintain uniform thickness.

Cooling and Solidification

Once the molten aluminum is in the mold, it begins to cool and solidify. Proper cooling is essential to prevent defects such as shrinkage or warping. The cookware is allowed to cool slowly to ensure even solidification and maintain the integrity of the final product.

Post – Casting Processing

After the cookware has solidified, it is removed from the mold. Post – casting processing may include trimming excess material, surface finishing, and quality inspection. These steps ensure that each piece of cookware meets the highest standards of quality and appearance.

Assembly and Packaging

The final stage involves assembling the various parts of the cookware, such as attaching handles and lids. The cookware is then cleaned, polished, and packaged for distribution. Proper assembly and packaging ensure that the cookware is ready for use and protected during transportation.

HAICHEN: Your Complete Solution Partner for Cast Aluminum Cookware

HAICHEN is more than a die casting machine supplier. We are a full-solution partner for cookware makers, offering everything from molds to process help. We understand the tough needs for surface finish, even wall thickness, and fast production speed in cookware making.

- Core Technology Strength

- Mold and Process Teamwork

- Customer Case: Boosting Output for High-End Non-Stick Pans

Core Technology Strength

HAICHEN machines have precise injection and control systems. They can change speed and pressure in milliseconds. This is vital for making cookware with complex patterns or thin walls. It ensures the metal fills the mold smoothly and avoids surface marks or cold spots.

Mold and Process Teamwork

Our engineers can join early mold reviews. We use flow simulation to improve the gate and runner design. This boosts material use and product yield from the start. We also give ongoing process support to help customers start stable production quickly.

Customer Case: Boosting Output for High-End Non-Stick Pans

A well-known kitchenware brand needed to make a line of aluminum non-stick fry pans. The pans had fine anti-slip patterns and needed a very good surface.

- Challenge: Their old line was not efficient. The complex patterns often did not fill completely, causing a high reject rate.

- HAICHEN Solution: We provided a HAICHEN 680-ton cold chamber die casting machine and improved the mold cooling plan. We used the machine’s fast-response injection system to control the metal speed with precision.

- Result: The new line cut the cycle time by 22%. The pattern clarity improved a lot. The defect rate from filling problems dropped below 0.8%. This helped the customer greatly improve its competition in the high-end market.

HAICHEN: Your Partner in Cast Aluminum Cookware Manufacturing

At HAICHEN, we specialize in providing high – quality die casting machines and molds designed for precision and efficiency. Our machines are equipped with advanced features that ensure consistent performance and high – quality production. Whether you are starting a new production line or looking to upgrade your existing equipment, HAICHEN has the solutions to meet your needs.

The manufacturing process of cast aluminum cookware involves several key steps, from material preparation to final assembly. By focusing on precision engineering, advanced casting techniques, and post – casting processing, manufacturers can produce high – quality and durable cookware.