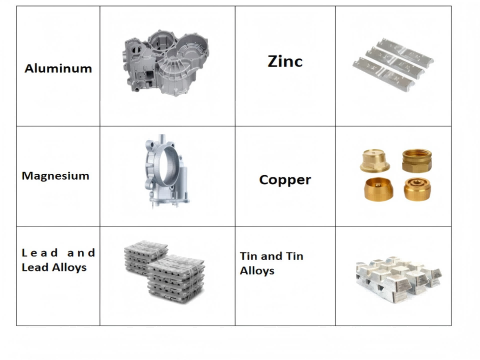

The material selection for die casting mainly include: Aluminum alloy, Magnesium alloy, Zinc alloy, Copper alloy, Lead-tin alloy.

Firstly to consider is the performance requirements of the material, including mechanical properties, heat resistance, corrosion resistance, and forFmability.

Different die-casting materials are suitable for different application scenarios, so the material selection for die casting should be based on below specific application requirements.

In short, what is the selection of die-casting material ? The factors such as material performance requirements, cost-effectiveness, environmental friendliness, and compatibility with the production process should be comprehensively considered to ensure the quality and production efficiency of the final product.

Mechanical properties of materials

Die casting materials need to have good mechanical properties to ensure the strength and durability of the final product. For example, aluminum alloy is widely used in the production of automotive parts due to its high strength and good formability. Magnesium alloys have a wide range of applications in fields such as automobiles and motorcycles due to their lightweight and high-strength properties.

Heat resistance and corrosion resistance

During the die-casting process, the mold and materials will experience high temperatures and corrosive environments, so the material selection with good heat resistance and corrosion resistance is crucial.

Forming performance

The forming performance of die-casting materials directly affects the quality and production efficiency of products.

Cost effectiveness

Cost is also an important factor to consider when selecting for die casting materials, while meeting performance requirements. Although imported materials have superior performance, they are expensive, while domestically produced materials are relatively cheaper and can be selected according to the economic conditions and product needs of the enterprise.

Environmental protection and sustainability

With the increasing awareness of environmental protection, choosing renewable or easily recyclable materials has become increasingly important. For example, magnesium alloys have advantages in green manufacturing due to their easy recycle ability.

Process compatibility

The material selection for die casting should also consider their compatibility with existing production processes. For example, optimizing the composition and melt quality of aluminum alloy materials, improving the design and process parameters of die-casting molds, can significantly enhance the dimensional accuracy and surface quality of products.

Environmental considerations for die-casting metal materials

In essence, no industrial process is truly “environmentally friendly”, and metal die casting is no exception. It is an energy-intensive process with significant environmental impacts concerning emissions, energy consumption, and waste. However, the unique and virtually infinite recyclability of metals, coupled with modern pollution control and process efficiencies, renders its environmental profile highly complex.

The environmental impact of non-ferrous metal die casting production represents a direct trade-off between its high energy consumption and the unparalleled ability to recycle scrap metal into high-value, durable products. Consequently, its sustainability hinges not on the process itself, but on the specific energy sources, waste management systems, and emission control measures implemented by the foundry and die casting:

- Key Environmental Impacts of Metal Die Casting

- Contradictory Arguments Regarding the Sustainability of Metal Die Casting

Key Environmental Impacts of Metal Die Casting

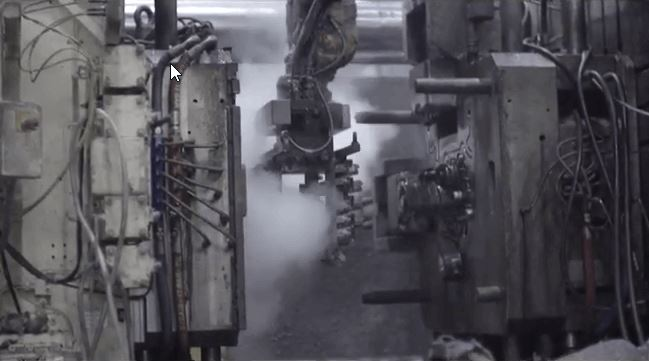

To understand the environmental footprint of casting, we must first deconstruct its core operational challenges. Each step from melting to finishing introduces distinct impacts.

High Energy Consumption

Melting metal requires immense thermal energy. This constitutes the largest contributor to casting’s environmental footprint.

This energy is typically derived from the combustion of fossil fuels (such as natural gas or diesel for aluminium alloy die-cast products) or electricity. Consequently, a casting’s carbon footprint is directly linked to the carbon intensity of its energy source.

Air Emissions

The high-temperature processes involved in die-casting production generate several types of air pollutants.

Primary emissions include carbon dioxide (CO₂) from fuel combustion, particulate matter (dust and metal fumes), and volatile organic compounds (VOCs). VOCs are typically produced by the thermal decomposition of chemical binders used in sand mould fabrication.

Waste Generation

The metal die-casting process generates several waste streams requiring careful management.

Primary wastes include impurities skimmed from molten metal—known as slag—and dust collected from emission control systems.

Contradictory Arguments Regarding the Sustainability of Metal Die Casting

Despite existing challenges, metal die casting possesses robust characteristics conducive to the circular economy. Neglecting these aspects presents an incomplete picture.

Unparalleled Recyclability

This represents casting’s foremost environmental advantage. Metal alloys such as aluminium, lead, zinc, magnesium, and copper can be recycled almost indefinitely without diminishing their structural properties.

Die casting is inherently a recycling operation, transforming scrap metal – from end-of-life vehicles to manufacturing by-products – into new, complex, critical components. This significantly reduces the demand for primary ore extraction, an inherently environmentally disruptive process.

Near-Net-Shape Manufacturing

Die casting excels at producing intricate components to near-final dimensions, a process termed ‘near-net-shape’ manufacturing.

This minimises the need for subsequent machining, yielding substantial energy savings and, crucially, reducing material wastage. Metal die casting directly forms shapes rather than carving away 50% of solid metal blocks to create parts.

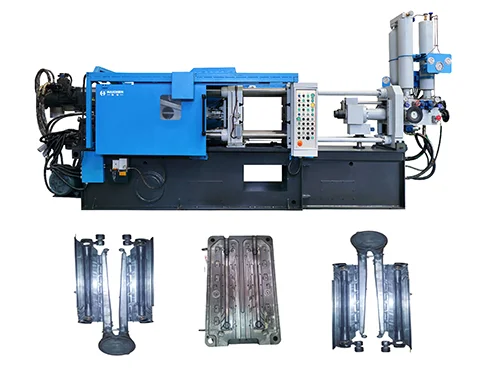

Haichen machine material selection for die casting

Haichen machinery produces high pressure die casting machines. It includes both cold chamber die casting machines and hot chamber die-casting machines.They have high durable and precise features. For example, Haichen cold chamber die casting machine is suitable for material of AL(aluminium) and MG(magnesium) for die casting.