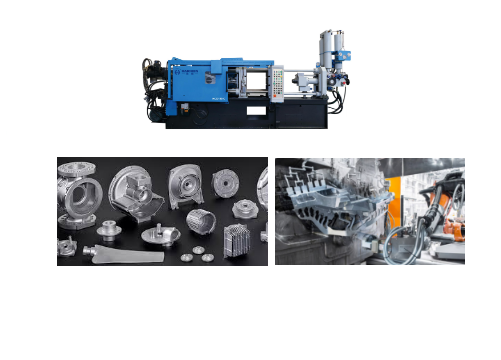

The Materials of die casting machine, such as aluminum, zinc, and magnesium alloys, are chosen for their unique properties that facilitate efficient production and high – quality part manufacturing.

In the die – casting industry, the choice of material is crucial for achieving high – quality, durable, and functional parts.

Die – casting machines are designe to work with a variety of materials, but the most commonly use are aluminum, zinc, and magnesium alloys.

These materials offer a unique combination of properties that make them ideal for a wide range of applications.

This article will explore the key characteristics and applications of these materials, as well as how modern die – casting machines are optimize to work with them.

Aluminum Alloys

- Properties

- Applications

- HAICHEN’s Optimization

Properties

Aluminum alloys are known for their excellent strength – to – weight ratio, making them ideal for applications where weight reduction is crucial. They also offer good corrosion resistance, high thermal and electrical conductivity, and excellent machinability. These properties make aluminum alloys suitable for a wide range of applications, including automotive, aerospace, and consumer electronics.

Applications

Aluminum alloys are widely use in the automotive industry for engine components, transmission housings, and structural parts. In the aerospace industry, they are use for aircraft structural components and engine parts. Aluminum alloys are also popular in consumer electronics for their lightweight and durable properties.

HAICHEN’s Optimization

HAICHEN’s die – casting machines are designe to handle aluminum alloys efficiently. Our machines feature advanced temperature control systems to ensure optimal melting and injection conditions. The high – precision injection systems ensure that the molten aluminum fills the mold cavity uniformly, resulting in high – quality parts with intricate details and tight tolerances.

Zinc Alloys

- Properties

- Applications

- HAICHEN’s Optimization

Properties

Zinc alloys are known for their high strength, good wear resistance, and excellent dimensional stability. They also offer good corrosion resistance and are easy to cast, making them suitable for intricate and detailed parts. Zinc alloys are particularly useful for applications requiring high – precision and thin – walled components.

Applications

Zinc alloys are commonly use in the automotive industry for small – to – medium – sized components such as connectors, brackets, and housings. They are also used in the consumer goods industry for decorative parts, door handles, and locks. Zinc alloys are ideal for applications where appearance and precision are critical.

HAICHEN’s Optimization

HAICHEN’s die – casting machines are optimize for zinc alloy casting. Our machines feature advanced cooling systems to ensure rapid and uniform solidification of the molten zinc. The high – precision molds and injection systems ensure that even the most intricate designs can be produce with high – quality surface finishes and tight tolerances.

Magnesium Alloys

- Properties

- Applications

- HAICHEN’s Optimization

Properties

Magnesium alloys are the lightest of the commonly use die – casting materials, offering excellent strength – to – weight ratios. They also provide good damping characteristics and high – strength properties, making them suitable for applications requiring lightweight and high – performance components.

Applications

Magnesium alloys are widely use in the automotive and aerospace industries for structural components, engine parts, and interior components. They are also used in consumer electronics for lightweight and durable casings. Magnesium alloys are ideal for applications where weight reduction and high – strength are critical.

HAICHEN’s Optimization

HAICHEN’s die – casting machines are designed to handle magnesium alloys with precision and efficiency. Our machines feature advanced safety systems to manage the reactivity of magnesium, ensuring a safe and controlled casting process. The high – precision injection systems ensure that the molten magnesium fills the mold cavity uniformly, resulting in high – quality parts with intricate details and tight tolerances.

HAICHEN: Process Co-Optimization Based on Material Properties

HAICHEN not only supplies die casting machines for different materials but also focuses on deep matching between material properties and process parameters. Our engineering team can provide integrated solutions, from material selection advice to full process optimization, based on your specific product needs.

- Engineering Support for Material-Process Matching

- Case Study: Material-Process Synergy for an Aluminum Structural Part

Engineering Support for Material-Process Matching

For magnesium auto parts where extreme lightweight is key, HAICHEN emphasizes mold venting and melt protection systems, plus precise temperature control to handle magnesium’s oxidation tendency and narrow solidification range. For zinc decorative parts needing perfect surfaces, we focus on superior mold polishing and even cooling to ensure flawless detail reproduction.

Case Study: Material-Process Synergy for an Aluminum Structural Part

A customer needed to produce large aluminum battery trays and struggled to choose between “high strength” and “high elongation” material requirements, while also facing inconsistent yield rates.

- HAICHEN Analysis & Recommendation: Our engineers found that the customer’s current A380 alloy met strength needs but lacked sufficient elongation, causing micro-cracks during assembly. We recommended switching to the more ductile A365 alloy and provided a complete optimized process package for it, including higher mold temperature, adjusted high-speed switch points, and intensification settings.

- Result: After implementing the new material and process on HAICHEN machines, the product’s elongation improved by over 50%, solving the assembly cracking issue. Moreover, because the process was well-matched to the material, the cycle time remained stable, and the overall yield rate increased from 91% to 96%.

HAICHEN’s Comprehensive Solutions

Advanced Machine Design

HAICHEN’s die – casting machines are engineered to work seamlessly with aluminum, zinc, and magnesium alloys. Our machines feature advanced temperature control, precise injection systems, and efficient cooling mechanisms to ensure optimal performance and part quality.

- Customized Solutions

- Technical Support

Customized Solutions

We offer customized die – casting solutions to meet the specific needs of our customers. Our team of experts can help select the right alloy and machine configuration based on the desired properties and application requirements. Whether you need high – strength components or lightweight parts with intricate details, HAICHEN can provide the appropriate solution.

Technical Support

HAICHEN provides comprehensive technical support to assist with material selection, process optimization, and troubleshooting. Our goal is to help our customers achieve high – quality results and maintain efficient production processes.

Choosing the right material for die – casting is essential for achieving high – quality, durable, and functional parts.

Aluminum, zinc, and magnesium alloys each offer unique properties that make them suitable for a wide range of applications.

By understanding the characteristics and applications of these materials, manufacturers can make informed decisions to optimize their production processes.

As a leading manufacturer of die – casting machines. HAICHEN is committed to providing advanced solutions and comprehensive support to help our customers achieve success in their die – casting operations.