Reducing energy consumption of hydraulic valves can be achieved through methods such as optimizing valve design for minimal pressure loss, implementing energy – efficient control systems, using variable – speed drives, and conducting regular maintenance to ensure optimal performance.

In the die casting industry, hydraulic valves play a crucial role in controlling the flow and pressure of hydraulic fluid.

However, these valves can also be significant consumers of energy. Reducing the energy consumption of hydraulic valves not only helps lower operational costs but also contributes to a more sustainable manufacturing process.

This article explores various methods to reduce energy consumption in hydraulic valves, contributing to more efficient die – casting processes.

Optimize Valve Design

- Use of Efficient Valve Types

- Valve Sizing

Use of Efficient Valve Types

Different types of hydraulic valves have varying levels of energy efficiency. For example, proportional valves can offer more precise control with lower energy consumption compared to traditional on – off valves. HAICHEN’s machines are designed with advanced proportional valves that provide optimal performance while minimizing energy use.

Valve Sizing

Ensuring that the hydraulic valves are correctly sized for the application is essential. Over – sized valves can lead to unnecessary energy consumption, while under – sized valves may not provide sufficient flow. Proper sizing ensures that the valve operates efficiently within its designed parameters.

Implement Advanced Control Systems

- Digital Controls

- Load – Sensing Systems

Digital Controls

Advanced digital control systems can significantly reduce energy consumption by providing precise control over valve operation. These systems can adjust the valve’s position and flow rate in real – time, ensuring that only the necessary amount of energy is use. HAICHEN’s machines are equip with state – of – the – art digital controls that enhance energy efficiency.

Load – Sensing Systems

Load – sensing hydraulic systems adjust the amount of hydraulic fluid delivered based on the actual load requirements. This reduces energy consumption by avoiding over – pressurization and unnecessary fluid flow. HAICHEN’s machines feature load – sensing systems that optimize energy use during operation.

Regular Maintenance

- Cleaning and Inspection

- Lubrication

Cleaning and Inspection

Regular cleaning and inspection of hydraulic valves can help identify and address issues that may lead to energy inefficiencies. Contaminated or worn – out valves can increase energy consumption and reduce performance. HAICHEN recommends a routine maintenance schedule to ensure valves are operating at peak efficiency.

Lubrication

Proper lubrication of hydraulic valves reduces friction and wear, which can lead to lower energy consumption. Regularly check and replace lubricants as needed to maintain optimal valve performance.

System Optimization

- Pressure Optimization

- Flow Optimization

Pressure Optimization

Optimizing the hydraulic system’s pressure settings can reduce energy consumption. By setting the pressure to the minimum required level for the application, unnecessary energy use can be avoided. HAICHEN’s machines allow for easy adjustment of pressure settings to ensure optimal energy efficiency.

Flow Optimization

Adjusting the flow rate of the hydraulic fluid to match the specific requirements of the die casting process can also reduce energy consumption. HAICHEN’s machines are designed to provide precise flow control, ensuring efficient operation.

Training and Education

Training operators and maintenance personnel in energy – efficient practices is crucial. Proper training helps staff understand the importance of energy efficiency and how to optimize the operation of hydraulic valves. This includes learning how to identify and address energy – wasting issues, as well as implementing best practices for valve maintenance and operation. Educated staff can contribute to more efficient and sustainable die – casting operations.

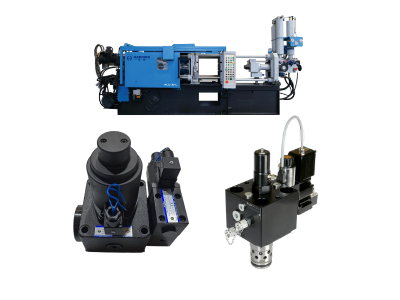

HAICHEN Hydraulic Valves Energy Efficiency Optimization

- Advanced Valve Designs

- Customized Solutions

- Integration with Intelligent Control Systems

Advanced Valve Designs

HAICHEN offers hydraulic valves designed for optimal energy efficiency. These valves feature advanced designs that minimize pressure loss and improve overall system performance. By using HAICHEN’s high – efficiency valves, manufacturers can achieve significant energy savings without compromising on performance.

Customized Solutions

HAICHEN provides customized hydraulic valve solutions tailored to specific die – casting applications. Our team of experts can help optimize valve settings and configurations to meet the unique requirements of your production process.

Integration with Intelligent Control Systems

HAICHEN’s hydraulic valves are designed to work seamlessly with intelligent control systems. These systems can monitor and adjust valve settings in real – time, ensuring optimal energy use and reducing waste.

HAICHEN: Your Partner in Energy – Efficient Die Casting

At HAICHEN, we engineer high-quality die casting machines to maximize energy efficiency and sustainability. Our advanced hydraulic systems optimize energy use while maintaining peak performance. Whether you are looking to reduce operational costs or improve your environmental footprint, HAICHEN has the solutions to meet your needs.

Reducing the energy consumption of hydraulic valves is essential for achieving efficient and sustainable die casting operations. By optimizing valve design, implementing advanced control systems, performing regular maintenance, and optimizing system settings, manufacturers can significantly reduce energy use. Mastering techniques for Reducing Hydraulic Valve Energy Use can lead to substantial cost savings and environmental benefits.