Oil consumption of machine burner: how much oil will be used during the machine burner working. The Oil consumption of machine burner is the main part to calculating the cost of the production.

The fuel consumption of the combustion furnace of a hot chamber die casting machine can be affected by a variety of factors.

And including the furnace type, combustion efficiency, fuel type and grade, and the efficiency grade of the burner.

Therefore, in order to accurately calculate the oil consumption of the combustion furnace of the hot chamber die casting machine.

It is necessary to know the furnace type, combustion efficiency, fuel type and grade, and the efficiency class of the burner.

Common furnace types for hot chamber die casting machine burners

The common furnace types of hot chamber die casting machine combustion furnaces mainly include coal furnaces (coke furnaces), electric furnaces and oil furnaces.

Combustion efficiency of the hot chamber die casting machine furnace

The calculation method of the combustion efficiency of the combustion furnace of the hot chamber die-casting machine can refer to the calculation method of the thermal efficiency of the gas heating furnace.

The calculation of the thermal efficiency of the furnace is usually based on the positive equilibrium method and the reverse equilibrium method.

- Positive equilibrium method

- Reverse equilibrium method

Positive equilibrium method:

Thermal efficiency is calculated by directly measuring the input and output heat of the furnace.

This method is simple and intuitive, but requires accurate measurement of the input and output heat.

Reverse equilibrium method:

Thermal efficiency is calculated by testing and calculating the heat loss of the heating furnace (including the heat loss of chemical incomplete combustion, exhaust gas heat loss, heat dissipation loss, etc.).

This method allows for a more comprehensive consideration of various heat losses, thus improving the accuracy of the calculations.

How to estimate the fuel consumption of a hot chamber die casting machine based on its specific parameters?

To estimate the fuel consumption of a hot chamber die casting machine combustion furnace.

And several specific parameters and process conditions need to be considered.

Here are the detailed steps and how:

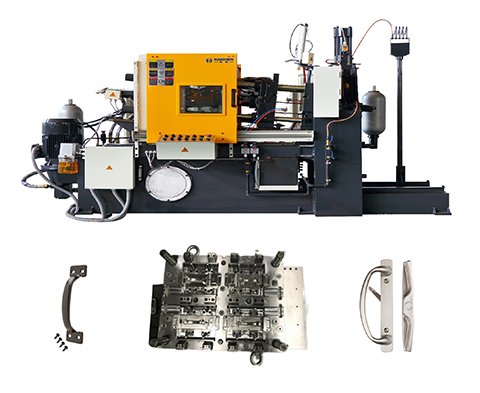

The working principle of a hot chamber die casting machine is to inject molten metal into a mold through a gooseneck tube for die casting.

Such equipment usually has the advantages of high production efficiency and low metal consumption.

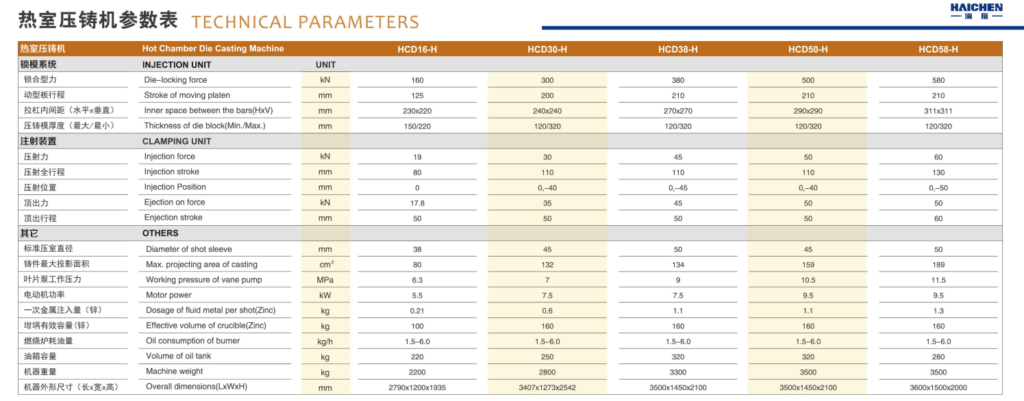

It is necessary to consult the technical parameter table of the hot chamber die casting machine

Which includes but is not limited to injection speed, injection pressure, mold temperature, etc.

The following is the parameter table of Haichen hot chamber die casting machine:

Different types of combustion furnaces (e.g., oil-fired furnaces, gas furnaces) have different thermal efficiency and fuel consumption.

The fuel consumption of the combustion furnace needs to be estimated according to the specific model and specification of the furnace.

Based on the process parameters of the hot chamber die casting machine.

Such as injection speed and injection pressure, the heat that needs to be supplied by the combustion furnace can be estimated.

Based on the thermal power requirements of the combustion furnace and its thermal efficiency, its fuel consumption can be estimated.

Estimating the fuel consumption of the combustion furnace of the hot chamber die casting machine needs to comprehensively consider the technical parameters of the equipment.

The process conditions, and the type and specification of the combustion furnace.

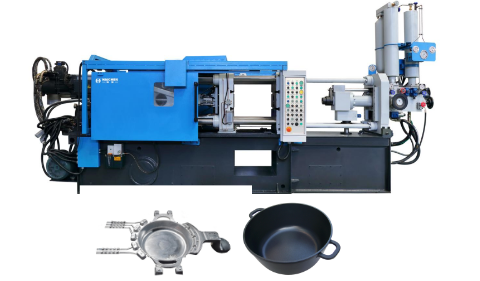

Haichen die casting machine

Haichen not only provides equipment sales.

But also assists customers to solve technical problems and ensure the safety and normal operation of equipment.

Our technical support team is able to provide comprehensive operation and maintenance training to help customers get the most out of their equipment.

Our die casting machines occupy an important position in the market with their high precision, high efficiency, adaptability, energy efficiency.

And continuous technical improvement and service support, and provide customers with an excellent product and service experience.