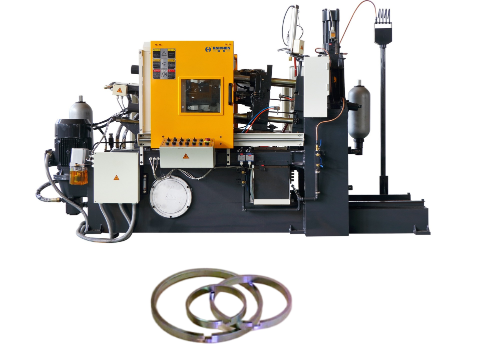

Plunger Rings also known as the injection sleeve or pressure ring is one of the core components of the injection system of the die-casting machine.

It mainly transmits pressure, seals the molten metal flow channel, and withstands mechanical and thermal shock in high-temperature, high-pressure environments.

As a leading manufacturer of shot end components for die casting, Haichen Machinery has longbeen an industry leading supplier of quality, top-notch plunger rings.

Our customers have a wide rangeof die casting needs, which is why we stock a large variety of plunger rings in standard inch and metricsizes.

The function of the Plunger Rings

- Pressure transmission

- Sealing and guidance

- Thermal management

Pressure transmission

The hydraulic system generates pressure and transmits it through the injection rod to the molten metal, achieving high-speed filling.

Sealing and guidance

Ensure that there is no leakage of molten metal during the injection process.

And at the same time maintain the coaxiality between the injection rod and the injection chamber to reduce friction loss.

Thermal management

The built-in cooling system (e.g., a water-cooled aisle) controls the temperature of the injection ring to avoid deformation or failure due to thermal expansion.

Structural design of the plunger rings

- Main structure

- Combined Injection Ring

- Open steel ring design

Main structure

It adopts a hollow box design, and reinforcing ribs are arranged inside to improve the structural strength.

Integrated cooling system, including inlet pipes, outlet pipes and circulating water channels for rapid heat dissipation.

The design of the connecting pin hole and mount allows for precise docking with the mold and other components of the injection system.

Combined Injection Ring

Engineers employ a split lining structure such as a copper alloy and steel shell combination in high-pressure erosion environments to significantly extend the service life of equipment.

Open steel ring design

During high-pressure injection, the molten metal opens the steel ring to enhance the sealing and reduce the formation of burrs in the pressure chamber.

Haichen’s proprietary forging process produces high-strength, high-integrity plunger rings that exhibit optimal performance in high-temperature and corrosive environments.

Material selection and performance requirements

- Non-ferrous metals

- Special alloys

- Stainless steel

- Material selection trade-offs

Non-ferrous metals

Injection rings need to have high strength, wear resistance, corrosion resistance and thermal fatigue resistance.

Such as ZcuA18Mnl3Fe3 bronze alloy, which has excellent high temperature resistance and is suitable for high-frequency injection scenarios.

Vacuum quenching high-carbon chromium steels such as X46Cr13/X46Cr14 achieves high surface hardness (HRC 45-50) and significantly improves wear resistance.

Special alloys

Hastelloy C alloy is resistant to speckle and oxidation and is suitable for use in corrosive media environments.

Stainless steel

Type 316 stainless steel resists chloride corrosion effectively.

Ultra-pure gas sealing systems utilize gold-plated stainless steel for enhanced reliability.

Material selection trade-offs

Increasing hardness increases wear resistance but reduces toughness, and heat treatments such as carburizing and nitriding balance these properties.

Haichen’s pressure rings are typically made from high-strength materials such as H13 tool steel, tungsten carbide, or ceramic coatings to withstand high temperatures, pressures, and wear.

Combine materials, thermal management, and sealing properties in design to balance cost and efficiency.

Maintenance and maintenance of the injection ring

- Coaxiality calibration

- Wear detection

- Cooling system maintenance

- Lubrication management

Coaxiality calibration

Check the coaxiality of the injection chamber and the injection rod every month, and control the deviation at ≤0.05mm to prevent eccentricity.

Wear detection

Observe the punch gap,if the speed is abnormal or the molten metal splashes, replace the wear parts.

Cooling system maintenance

Clean up the scale of the cooling water circuit every six months, and use chemicals to remove the scale to ensure the efficiency of heat dissipation.

The cooling water needs to be purified (e.g. in a filter tower) to avoid impurities clogging the pipes.

Lubrication management

Lithium grease or molybdenum disulfide is used to fill all lubrication points monthly to avoid excessive seals falling off.

ISO VG 46 (46 centstoke at 40°C) is recommended for hydraulic oil viscosity and seals and wear rings are replaced every 5 years.

Plunger Rings Technological development trends

- Material innovation

- Intelligent monitoring

- Composite coating technology

Material innovation

Beryllium-free copper alloys, such as the Wieland CaroTec series, are on the rise due to the need for environmental protection, balancing strength and safety.

Intelligent monitoring

Integrated sensors monitor piston ring temperature and wear in real time, predict replacement cycles through AI, and reduce unplanned downtime.

Composite coating technology

DLC (diamond-like carbon) coating is superimposed with nitriding layer, the coefficient of friction is reduced to 0.05, and the service life is increased by 40%.

Haichen——A Trusted Source for Plunger Rings

As a leading manufacturer of shot end components for die casting, Haichen has long been an industry leading supplier of quality, top-notch plunger rings.

Our customers have a wide range of die casting needs, which is why we stock a large variety of plunger rings in standard inch and metric sizes.

Our extensive inventory allows us to offer same day shipping to all of our clients.

We have a wealth of experience in our quality plunger rings, and can help you get the components you need quickly and with ease.

If you would like a quote for any standard or custom components or have any questions regarding our shot end component manufacturing please contact us.