Understanding Plunger rod material specifications is crucial for ensuring high – quality and efficient die casting production.

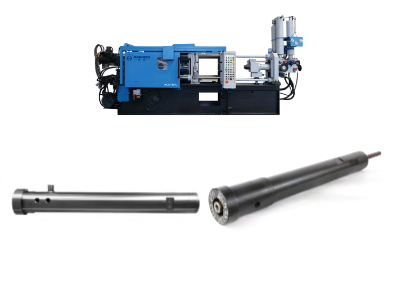

In the die casting industry, the plunger rod is a critical component that ensures the smooth injection of molten metal into the mold cavity.

The material used for the plunger rod must meet specific requirements to withstand the high temperatures and pressures of the die casting process.

This article will explore the material specifications for plunger rods and why they are crucial for high – quality die casting production.

Key Material Requirements

- High – Temperature Resistance

- Durability and Strength

- Corrosion Resistance

High – Temperature Resistance

The plunger rod must be able to withstand the extreme temperatures of molten metal without deforming or losing its structural integrity. Engineers commonly select materials such as high-temperature alloys and specialized steels to meet this requirement.

Durability and Strength

The plunger rod undergoes significant mechanical stress during the injection process. Therefore, manufacturers must construct it from durable and strong materials. Engineers prefer high-strength steel and alloy materials because they withstand repetitive stress without breaking or wearing down.

Corrosion Resistance

Molten metal can be highly corrosive, so the plunger rod must be resistant to chemical attack. Materials with high corrosion resistance, such as stainless steel or specialized alloy coatings, are essential to prevent degradation and ensure long – term performance.

Common Materials Used

- High – Strength Steel

- Alloy Materials

- Stainless Steel

High – Strength Steel

High – strength steel is a popular choice for plunger rods due to its excellent balance of strength and durability. It can withstand the high pressures and temperatures of the die casting process while maintaining its shape and function.

Alloy Materials

Specialized alloys, such as those containing tungsten or molybdenum, are also used for plunger rods. These materials offer enhanced strength and temperature resistance, making them suitable for demanding die casting applications.

Stainless Steel

Stainless steel is valued for its corrosion resistance and strength. It is often used for plunger rods in applications where resistance to chemical attack is crucial.

Importance of Material Selection

Choosing the right material for the plunger rod is essential for several reasons:

- Efficient Metal Injection: The right material ensures that the plunger rod can inject molten metal smoothly and consistently, reducing defects and improving part quality.

- Long – Term Reliability: High – quality materials increase the lifespan of the plunger rod, reducing maintenance and replacement costs.

- Safety: Materials that can withstand high temperatures and pressures without failure contribute to a safer working environment.

HAICHEN: Your Partner in Die Casting Excellence

At HAICHEN, we specialize in manufacturing high – quality die casting machines with plunger rods made from the best materials.

Our machines are designed to provide precise control and efficient operation, ensuring that every part produced meets the highest standards.

Whether you are starting a new project or upgrading your existing equipment, HAICHEN has the solutions to meet your needs.

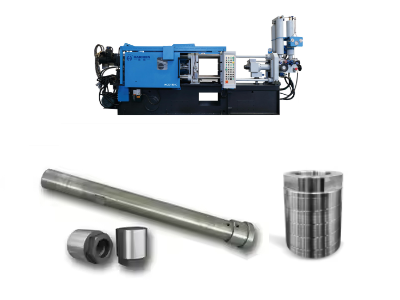

HAICHEN Plunger Rod Material Selection Criteria

HAICHEN does not equip all machines with plunger rods made from a single material. Instead, selections are differentiated based on machine tonnage, commonly used alloys, and production cycle times. For instance, for customers casting high-purity aluminum or magnesium alloys sensitive to iron contamination, rods made from H11 or premium H13 steel with special surface treatments (like nitriding) are prioritized to minimize iron pick-up. For high-volume standard aluminum alloy production, a more cost-effective material solution with enhanced wear resistance is employed.

Understanding the material specifications for plunger rods is crucial for achieving high – quality and efficient die casting production. By selecting materials that meet the key requirements of high – temperature resistance, durability, and corrosion resistance, manufacturers can ensure optimal performance and longevity of their plunger rods.