Principles of aluminum die casting is to inject molten aluminum alloy into the cavity of a precision mold under high pressure.

Cool and solidify under pressure, so as to form a casting of the desired shape.

Die casting or aluminium die casting is a high-volume manufacturing process that produces high-accuracy and precision metal parts.

The basic principle involves forcing molten metal, at high pressure, into a mould or ‘die’.

If you are designing die-cast aluminum parts or products, you may feel overwhelmed by the numerous factors to consider and be at a loss.

After all, the design refinement stage is one of the key steps for successfully and efficiently manufacturing die-cast products.

Fortunately, the experts in Haichen have extensive knowledge on how to design to achieve the best aluminum die-casting production. You can fully trust us.

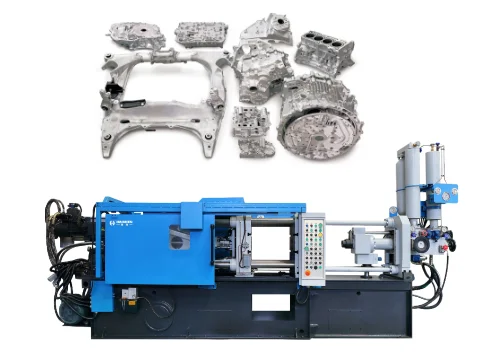

Aluminum Die Casting

Aluminum die casting is a casting process that uses high pressure to inject molten metal into the mold cavity at high speed, and then cools and solidifies under pressure.

The core of this is to use the characteristics of high pressure and high speed to enable the molten metal to quickly fill the mold cavity.

And complete the cooling and solidification in a short time, so as to obtain high-precision and high-quality castings.

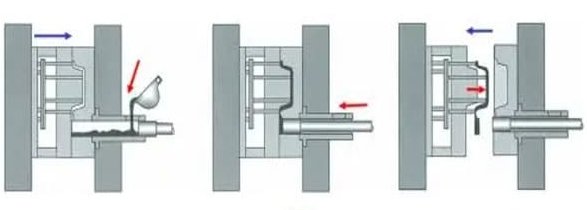

Aluminum Die Casting Process

- Melting

- Injection

- Cooling and solidification

- Mold opening and removal of castings

Melting

The aluminum ingots are heated to the melting point (usually 600-700°C) to allow them to completely melt into liquid metal.

Injection

Molten metal is injected into the mold cavity using high pressure, typically tens of megapascals.

Injection speeds are typically 16-80 m/s and even up to 80 m/s.

Cooling and solidification

The mold rapidly cools and solidifies the molten metal in its cavity.

Subsequently, this process completes within a notably short duration, typically spanning just seconds to tens of seconds.

Mold opening and removal of castings

After the mold is cooled, open the mold and take out the castings.

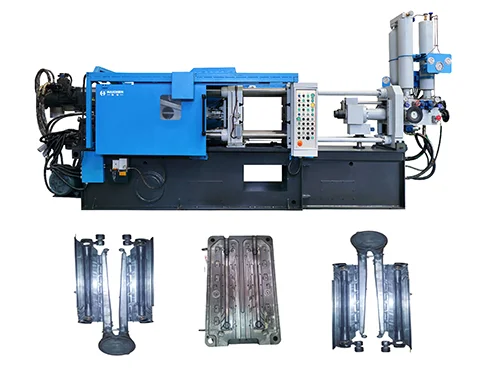

Aluminum Die Casting Machine

Used to provide high pressure and high speed molten metal injection capacity.

According to the clamping force, there are three categories small, medium and large machines.

According to the structure, there are two categories hot chamber die-casting machine and cold chamber die-casting machine.

Aluminum Die Casting Mould

The mold needs to be made of high-strength steel (such as H13, 2344, etc.).

And undergo precision machining to ensure the dimensional accuracy and surface quality of the casting.

The design rationality of the die-cast parts is closely related to the entire die-casting process.

When designing the die-casting mold, Haichen will fully consider the structural characteristics of the die-cast parts and the process requirements of die-casting, in order to minimize the defects that may occur during the die-casting process.

By adopting the optimal design scheme, the quality of the die-cast parts can be maximally improved.

Aluminum Die Casting materials

Commonly used aluminum alloys include rust-proof aluminum, duralumin, superduralumin.

And wrought aluminum, among which the LF series is the most widely used.

Aluminum Die Casting characteristics

- High efficiency

- High precision

- Strong adaptability to complex shapes

- High material utilization

High efficiency

The whole die casting process can be completed in a few seconds to tens of seconds, which is suitable for mass production.

High precision

Due to the precise mold design, the aluminum die casting has high dimensional accuracy, good surface finish and low roughness.

Strong adaptability to complex shapes

Aluminum die casting can produce parts with complex shapes and thin wall thicknesses.

Such as auto parts, electronic equipment housings, etc.

High material utilization

In the process of aluminum die-casting, the utilization rate of molten metal can reach 90%, which reduces material waste.

Advantages of Aluminum Die Casting

- High production efficiency

- High dimensional accuracy

- Excellent material properties

- Cost-effective

High production efficiency

Aluminum die casting can achieve high-volume production, producing thousands of parts per hour,

Which is suitable for large-scale industrial applications.

High dimensional accuracy

Due to the precise design of the mold and the high-pressure filling.

Aluminum die castings usually have extremely high dimensional accuracy and surface finish.

Excellent material properties

Aluminum and its alloys have good mechanical properties (e.g., high strength, high toughness), corrosion resistance.

And excellent electrical and thermal conductivity, making them ideal for many industrial sectors.

Cost-effective

Compared with other casting methods, aluminum die casting has lower processing costs and higher production efficiency.

Application areas of aluminum die casting

Aluminum die-casting is widely used in automobiles, aerospace, consumer electronics and other fields.

Mainly used to produce lightweight, high-strength parts, such as engine parts, automotive body structural parts, electronic equipment shells, etc.

Aluminum Die Casting Development trend

- Lightweight and energy saving

- Precision and complexity

With the increase in industrial demand and technological advances.

The aluminum die casting industry is developing in the following directions.

Lightweight and energy saving

The application of aluminum die casting in the field of automotive lightweight continues to expand.

The use of environmentally friendly materials (such as ADC12) and cold metal recycling technology.

Precision and complexity

By improving the mold design and process parameters, further improve the accuracy and complexity of the product.

As an efficient and precise metal casting process, aluminum die casting plays an important role in modern manufacturing industry.

Its lightweight, high efficiency and diverse applications make it an indispensable key technology in many industries.

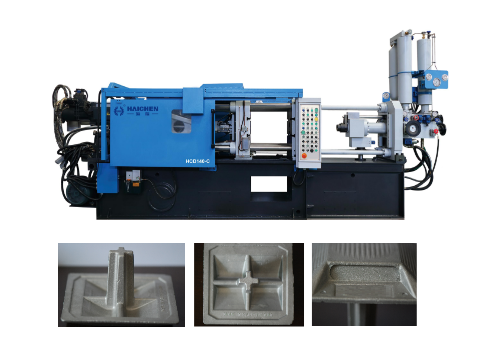

Haichen Aluminum Die Casting

Haichen Machinery is a manufacturer specializing in the production of precision die-casting machines and custom molds.

Aluminum die casting is an efficient, precise, and widely used manufacturing process.

Despite some challenges, the aluminum die casting process will continue to play an important role in several industries through technological innovation and optimization.

Since the establishment of the company, we have been committed to providing global customers with high-quality, high-precision and cost-effective die-casting production lines.

With strong engineering capabilities, advanced production equipment and a professional team, Haichen has become a reliable partner for our customers.