Precision die casting is a manufacturing process that involves injecting molten metal into a precision mold under high pressure to produce parts with high accuracy, consistency, and complex geometries.

Precision die casting produces complex metal parts with tight tolerances and superior surface finishes through a highly specialized manufacturing process.

It is widely used in various industries, including automotive, aerospace, electronics. And consumer goods, due to its ability to create parts with exceptional accuracy and consistency.

In this article, we will delve into the detailed process of precision die casting and explore why it is such a crucial technique in modern manufacturing.

Overview of Precision Die Casting Process

Precision die casting is a casting method that rapidly injects molten metal into a precision mold cavity under high pressure, and then solidifies it under pressure to obtain high-precision, high-strength metal parts. Compared with other casting methods, it has significant advantages:

- High Precision and Complexity: It can manufacture parts with complex shapes, precise dimensions, and smooth surfaces, significantly reducing subsequent machining and even achieving near-net-shape forming.

- High-Efficiency Production: The high-pressure, high-speed filling process is extremely short. Combined with automated equipment, the production cycle is fast, suitable for mass production, and effectively reduces unit costs.

- Superior Material Properties: Rapid cooling and solidification refines the grain size of the casting, resulting in excellent mechanical properties such as high strength, high hardness, and good wear resistance.

- Lightweight Potential: It is particularly suitable for lightweight alloys such as aluminum and magnesium, making it highly attractive to industries seeking lightweight solutions (such as automotive and aerospace).

Design and Tooling

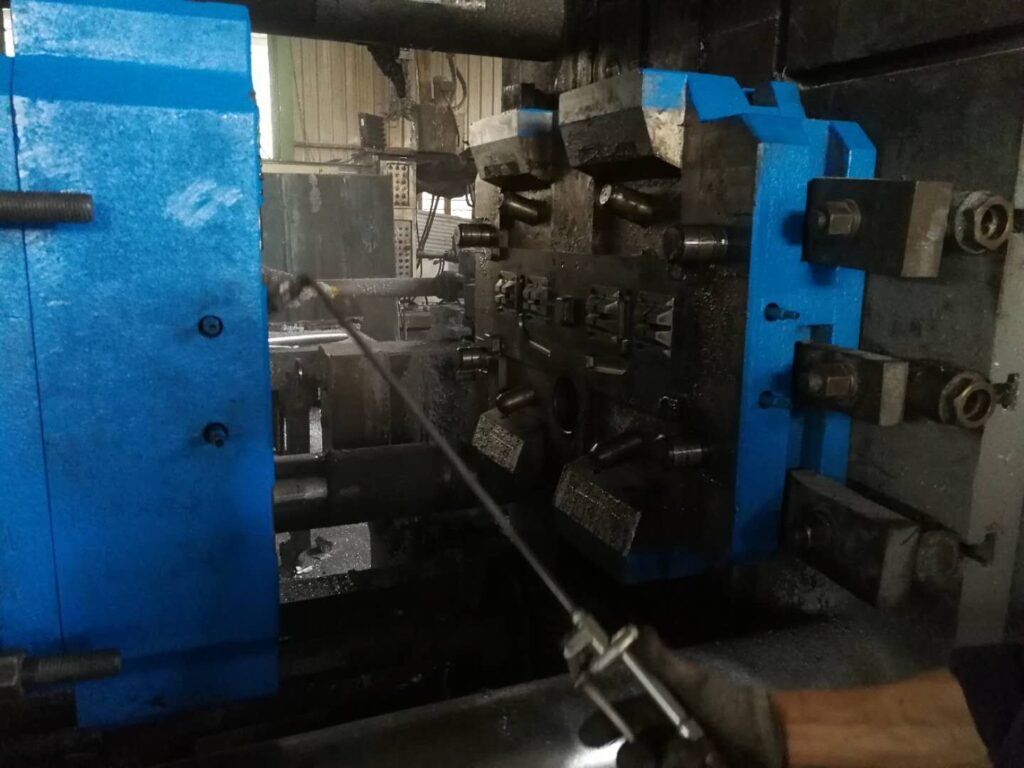

The first step in precision die casting is the design and creation of the mold, also known as the die. The die is typically made from high-grade tool steel and is designed to withstand the high pressures and temperatures involved in the casting process. The design of the die must be precise to ensure that the final part meets the required dimensions and tolerances.

HAICHEN, a leading die casting machine manufacturer, provides advanced tooling solutions to ensure high precision and durability. Our machines have state-of-the-art control systems that allow precise regulation of temperature and pressure, which is essential to achieving high-quality castings.

Material Preparation

A quality casting starts with clean, correctly mixed molten metal. Material prep is a basic step in the Process of Precision Die Casting.

- Alloy Selection and Mixing

- Melting, Refining and Degassing

- Precise Control of Melt Temperature

Alloy Selection and Mixing

Choose the alloy based on part needs, like aluminum alloy A380 or ADC12. We must tightly control the raw material mix. This ensures consistency between batches. It is the material base for a stable Process of Precision Die Casting.

Melting, Refining and Degassing

After melting in a furnace, the metal needs degassing and refining. This removes hydrogen gas and oxide impurities from the melt. It greatly reduces internal air holes and dirt defects in the casting.

Precise Control of Melt Temperature

The melt temperature must be kept within a strict range. Too low hurts fluidity and causes incomplete filling. Too high increases gas absorption and mold heat shock. Stable melt temperature is key for process control.

Injection

The high-pressure injection stage is the core of the Process of Precision Die Casting. It forces molten metal into the mold in an instant to form the part.

- Multi-Stage Injection Profile

- Real-Time Closed-Loop Control

- Matching Injection Speed and Pressure

Multi-Stage Injection Profile

Modern die casting machines divide injection into several stages. Typically, a slow speed first pushes air out of the shot sleeve. Then a high speed fills the cavity. Finally, very high pressure packs the metal to compensate for shrinkage. This multi-stage control optimizes filling.

Real-Time Closed-Loop Control

Advanced die casting machines use closed-loop control systems. They monitor injection speed and pressure in real time. They compare this with set values and make instant adjustments. This ensures process parameters are highly consistent for every shot.

Matching Injection Speed and Pressure

Different part structures need matched injection speed and pressure. Thin-walled parts need higher speed for complete filling. Thick-walled parts need higher pressure for density. Precise matching is key to getting quality castings.

Cooling and Solidification

After the casting solidifies in the mold, it needs proper handling to become a finished product. This is the final step in the Process of Precision Die Casting.

- Controlled Cooling and Mold Opening

- Automatic Ejection and Trimming

- Necessary Post-Processing Steps

Controlled Cooling and Mold Opening

The casting must cool in the mold long enough to solidify fully, but not too long to hurt efficiency. A scientifically set cooling time balances quality and output rate.

Automatic Ejection and Trimming

After solidifying, ejector pins push the casting out automatically. Then, the feed system and overflows are cut off by mechanical or automated means to get the casting blank.

Necessary Post-Processing Steps

As required, castings may need shot blasting, deburring, CNC machining, heat treatment, or surface finishing (like sand blasting, anodizing). This meets the final size, performance, and look standards.

Ejection and Post-Processing

Once the part has solidified, we eject it from the die. We carefully control the ejection process to prevent damage to the part. After ejection, the part may undergo additional post-processing steps, such as trimming, machining, or surface treatment, to achieve the final desired finish.

The process of precision die casting involves meticulous design, precise material preparation, controlled injection, and careful cooling and post-processing. Whether for automotive parts, aerospace components, or electronic housings, precision die casting remains a critical process in modern manufacturing.

HAICHEN Case Snapshots

- Automotive Lightweight Structural Parts

- Premium Cookware

- Case: New Energy Vehicle E-Drive Housing Production

Automotive Lightweight Structural Parts

HAICHEN collaborates with several automakers, utilizing its large-scale cold chamber die-casting machines. To produce aluminum alloy engine mounts and battery pack housings. Through integrated die casting, previously multiple sheet metal welded components are integrated into a single casting. Reducing weight by over 20% while enhancing structural rigidity, thus contributing to increased driving range for new energy vehicles.

Premium Cookware

HAICHEN’s aluminum cookware die-casting equipment provides solutions for high-end cookware brands. The die-cast aluminum pots are thick, durable, and offer even heat conduction. Combined with a ceramic coating, this enhances cooking performance and gives the products a modern and aesthetically pleasing appearance, satisfying consumers’ pursuit of a high-quality lifestyle.

Case: New Energy Vehicle E-Drive Housing Production

A parts maker needed to produce large aluminum e-drive housings. The part had a complex structure with uneven walls. It demanded very high leak-tightness and dimensional accuracy. They used an HAICHEN 880-ton cold chamber die casting machine with an optional vacuum system.

As a leading manufacturer of die casting machines, Haichen is committed to providing advanced and reliable equipment, enabling our customers to achieve the highest levels of precision and efficiency in their production processes. By understanding the precision die casting process, manufacturers can leverage its advantages and create high-quality products that meet today’s market demands.