Aluminium alloy road studs production demand includes applications and advantages, market demand and export situation and so on.

The production demand for aluminum alloy road stakes is driven by many factors. Including its superior performance, wide range of application scenarios, strong demand in the global market, and the specification of industry standards. However, the limited supply and price fluctuations of raw materials may have a certain impact on production costs and supply chain stability.

Aluminum alloy road warning studs have become the core facilities of modern traffic safety due to their high strength, long life, high visibility and environmental protection. Driven by global infrastructure upgrades, lightweight trends and low-carbon policies, their production demand will develop towards intelligence and high utilization of recycled materials in the future.

- Advantages of aluminum alloy road studs production demand

- Application scenarios of aluminum alloy road studs

- Market demand and export situation

- Overall trend of the aluminum alloy market

The production demand of aluminum alloy road studs are following aspects:

Advantages of aluminum alloy road studs

- Excellent durability

- High visibility and safety

- Environmental protection and economy

- Functional expandability

Aluminum alloy road studs have significant advantages over plastic road studs due to their durability and long service life. They are widely used in marking road signs, road boundaries and traffic signs. They can guide vehicles and ensure road safety. In addition, aluminum alloy road studs also have good reflective properties. And they are suitable for use at night or in low light environments.

Excellent durability of Aluminium alloy road studs production demand

- High compressive strength: Made of high-grade aluminum alloy, the static load-bearing capacity can reach more than 20 tons (die-cast aluminum process), suitable for high-load scenarios such as highways.

- Strong weather resistance: UV resistance, corrosion resistance, can withstand climatic conditions such as heavy rain, sandstorms, extreme temperature differences, and significantly extended service life (evidence shows that it can serve for a long time).

- Impact-resistant design: Reduce road damage by evenly dispersing traffic loads and resist repeated vehicle crushing.

High visibility and safety

- Strong reflective performance: Built-in prismatic glass or acrylic reflective sheet, double-sided reflection of headlights, nighttime visibility distance of more than 550 meters, effectively guiding lane boundaries.

- Adapt to complex environments: Maintain high recognition in low visibility conditions such as foggy and rainy days, reducing accident rates.

Environmental protection and economy

- Recyclable: Aluminum alloy is 100% recyclable, reducing resource consumption and carbon emissions, and complying with sustainable development policies.

- Low maintenance cost: Durability reduces replacement frequency, almost maintenance-free after installation, and saves municipal expenses in the long term.

Functional expandability of Aluminium alloy road studs production demand

- Solar integration: The die-cast aluminum housing is compatible with solar panels and supports LED active lighting, suitable for off-grid areas or emergency roads.

- Anti-slip design: Surface textures (such as rib structures) enhance friction to prevent pedestrians or vehicles from slipping.

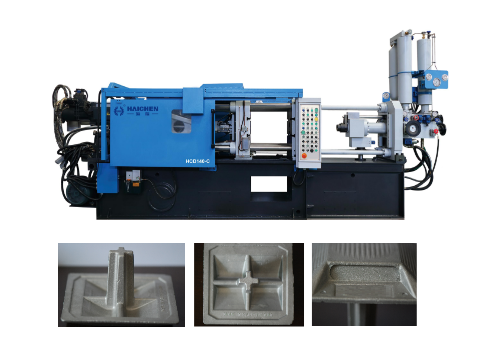

Haichen aluminium road stud production process

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Aluminium road stud production is a metal casting process that involves injecting molten metal under high pressure into a reusable mold cavity, known as a die. The die is usually made of two parts, the fixed half (also called the cover or cope) and the moving half (also called the ejector or drag).

The molten metal is forced into the die cavity through a runner system and solidifies rapidly to take the shape of the mold. Once the metal has cooled and solidified, the two halves of the die are opened, and the casting is ejected, leaving the die ready for the next cycle.

Cold chamber die casting is ideal for metals such as aluminum which have a high melting point. With this aluminum alloy stud die casting machine, during the process, metal is liquefied in a furnace at extremely high temperatures and then ladled into a cold chamber to be injected into the die.

A die casting mold is essentially made of two parts and consists of the fixed (stationary) and the movable (ejector) mold halves. The stationary die half is mounted on the die casting machine’s fixed fixing plate; the ejector die half is fixed to the movable fixing plate and contains the casting ejector.

Application scenarios of aluminum alloy road studs

- Traffic arterials

- Cities and special areas

- Energy saving and smart roads

In the future, with the further development of new energy vehicles and infrastructure construction, the market demand for aluminum alloy road studs is expected to continue to grow.

Traffic arterials

- Highways and national highways centerline and edge markings to guide traffic and warn of dangerous areas.

- Bridges and tunnel entrances to strengthen contour prompts.

Cities and special areas

- Pedestrian crossings, parking lots, and bus lanes.

- Emergency lanes, airport taxiways, and other scenes that require high reflectivity.

Energy saving and smart roads of Aluminium alloy road studs production demand

- Solar LED warning nails are used in power-deficient areas such as mountain roads and rural roads.

- Clean energy solutions reduce dependence on the power grid and reduce carbon emissions.

Market demand and export situation

- Aluminium alloy road studs production demand market demand growth

- Technology upgrade needs

- Policy and environmental pressure

Aluminum alloy road studs are not only in demand in the domestic market, but also exported to many countries or regions and areas. Such as North Korea, South Korea, Japan, Pakistan, Sri Lanka, Maldives, Russia, Ukraine and Moldova, etc. This shows that aluminum alloy road studs have a certain market demand worldwide.

Aluminium alloy road studs production demand market demand growth

- Global traffic safety standards are improving (such as the Mexican case), promoting the mandatory configuration of reflective facilities.

- China’s new energy and infrastructure expansion drive aluminum alloy demand. In 2023, the output of recycled aluminum will reach 5.8 million tons, and the transportation sector will account for more than 70%.

Technology upgrade needs of Aluminium alloy road studs production demand

- Die-casting aluminum technology has become the mainstream to replace plastics, meeting high load-bearing (20 tons +) and complex climate adaptability requirements.

- Surface anodizing treatment improves corrosion resistance and extends service life.

Policy and environmental pressure

- Low-carbon policies promote the application of recycled aluminum (such as ADC12 alloy accounts for 75% of the market) and reduce energy consumption in primary aluminum production.

- Lightweight trends (such as the automotive industry) drive the penetration rate of aluminum alloys in the transportation field to exceed 25%.

Overall trend of the aluminum alloy market

- The global aluminum alloy market has shown a growth trend in recent years. In 2019, global demand for aluminum rolled products reached 28.1 million tons. A record high, with the transportation industry being the main driving force.

- In addition, with the rapid development of new energy vehicles, the application of aluminum alloys in the automotive industry is also increasing, further driving the demand for aluminum alloy materials.

Regional Market Analysis

In the Asia-Pacific region, the demand for aluminum alloys continues to grow due to the rapid development of industrialization, urbanization and infrastructure construction. At the same time, the European and North American markets also have a high demand for aluminum alloy products due to strict environmental regulations and sustainable manufacturing practices.