Die Casting Machine Hydraulic system Failures can arise from multiple factors, It is a common transmission system error and often interrelated.

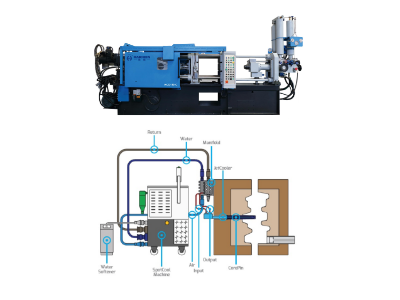

The hydraulic system of the die casting machine is one of its core components, responsible for providing power to drive the closing of the mold, the injection of metal, and the ejection of the casting. The hydraulic system transmits energy through high-pressure oil to ensure that the die casting machine operates with high precision and efficiency.

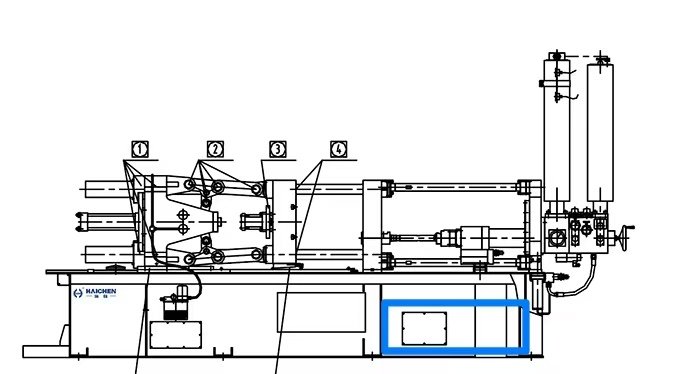

The control of the hydraulic system is usually completed by a PLC (Programmable Logic Controller) or a microprocessor, which monitors the system’s parameters such as pressure, flow and temperature in real time through sensors and automatically adjusts according to the preset program. For example, the Haichen C series cold chamber die casting machine uses a touch screen interface, and users can control the pressure, flow and unloading functions of the hydraulic system by setting parameters, thereby achieving precise control.

Haichen will list the main reasons for you:

Common causes of abnormalities

- Contamination

- Fluid-Related Issues

- Component Wear and Tear

- Maintenance Neglect

- Operational Factors

- Design and Installation Flaws

- Environmental Stress

- Electrical/Control Issues

Contamination

- Particulate Contamination: Metal shavings, dust, or debris from the die casting environment can infiltrate the hydraulic fluid, causing abrasive wear on pumps, valves, and seals.

- Water Ingress: Humidity or coolant leaks lead to water contamination, causing corrosion and reduced lubricity.

- Chemical Contamination: Breakdown of seals or incompatible fluids introducing harmful chemicals.

Fluid-Related Issues

- Thermal Degradation: Overheating from high operating temperatures or poor cooling degrades fluid, reducing lubrication and efficiency.

- Viscosity Problems: Incorrect fluid viscosity (too thick or thin) due to temperature extremes affects performance, leading to cavitation or poor pressure transmission.

- Oxidation: Aged or oxidized fluid forms sludge, clogging components and reducing heat dissipation.

Component Wear and Tear

- Seal/Hose Degradation: High heat and pressure cycles cause seals and hoses to harden, crack, or leak.

- Pump and Valve Wear: Continuous high-pressure operation erodes components like pistons, gears, and spools.

- Cylinder Damage: Injection cylinders suffer from scoring or seal failure due to contamination or misalignment.

Maintenance Neglect

- Infrequent Fluid/Filter Changes: Clogged filters or degraded fluid increase contamination risk.

- Ignoring Leaks: Unaddressed leaks lead to fluid loss, pressure drops, and air ingress.

- Lack of Inspections: Failure to monitor component condition or fluid quality accelerates system wear.

Operational Factors

- Overpressure: Excessive pressure settings stress components, causing bursts or fatigue.

- Aeration/Cavitation: Air entrapment in the fluid (aeration) or vapor bubbles (cavitation) reduces efficiency and damages pumps.

- Operator Errors: Incorrect settings or rapid cycling strains the system.

Design and Installation Flaws

- Undersized Components: Pumps or accumulators not rated for die casting demands lead to overwork and failure.

- Poor Assembly: Improper installation of hoses, fittings, or seals causes leaks or misalignment.

- Inadequate Filtration: Insufficient filtration systems allow contaminants to circulate.

Environmental Stress

- Thermal Cycling: Repeated expansion/contraction from temperature swings fatigues metal components.

- High Clamping Forces: Hydraulic systems supporting mold clamping endure extreme stress, leading to fatigue.

Electrical/Control Issues

- Solenoid/Sensor Failures: Malfunctions in electrical controls disrupt valve operation.

- Software Glitches: Incorrect control signals cause erratic hydraulic behavior.

Mitigation Strategies

- Regular Maintenance: Schedule fluid changes, filter replacements, and component inspections.

- Proper Fluid Selection: Use high-temperature-resistant, anti-wear hydraulic fluids.

- Contamination Control: Implement rigorous filtration and seal systems to block debris/water.

- Training: Ensure operators and technicians understand system limits and maintenance protocols.

- Monitoring Systems: Install sensors for pressure, temperature, and contamination to enable predictive maintenance.

By addressing these factors proactively, the reliability and lifespan of die casting machine hydraulic systems can be significantly enhanced.

What are the 4 reasons behind hydraulic system failure?

The four main causes of hydraulic system failure are as follows:

- Contamination

- Cavitation

- Overpressure

- Overheating

Contamination (hydraulic oil contamination)

Particles (such as metal debris, sand), chemical or biological contaminants in the hydraulic oil can cause component wear, oil line blockage and heat increase.

Large particles can cause the “phonograph” phenomenon of gear pumps and reduce efficiency; small particles (<5 microns) cause pressure imbalance and premature wear.

Contamination can also cause valve control to decrease, system overheating, and accelerate deposit accumulation, eventually causing component seizure.

About 60% of hydraulic failures are directly related to contamination.

Cavitation

When the vacuum at the pump inlet is too high (>5 inches of mercury), vapor bubbles will form in the oil. When these bubbles burst on the high-pressure side, they release high temperatures (locally up to 5000℉), damaging the wear plate and pump body.

Cavitation is often accompanied by a high-pitched noise, especially during cold starts. Its causes include blocked oil pipes, low oil temperature, clogged filters or insufficient oil tank level.

Air entering the system can also cause actuator abnormalities and control failures.

Overpressure

Exceeding the system design pressure will cause multiple component damage: input shaft breakage, housing rupture, seal failure and hose burst, etc.

When overpressure occurs, the oil will generate a sharp temperature rise through the small hole of the safety valve, which will accelerate the deterioration of the oil.

For example, under continuous overpressure, the pressure balance plate of the gear pump will wear quickly.

Overheating

High temperature is both the cause and consequence of Die Casting Machine Failures. Long-term overheating will reduce the viscosity of the oil (causing increased leakage), accelerate the aging of seals, and cause the hydraulic oil to fail due to oxidation.

For every 10°C increase in temperature, the oxidation rate of the oil doubles. Overheating is often caused by poor heat dissipation, continuous overload or internal leakage. It is necessary to monitor the oil temperature and keep the cooling system clean.

Other important factors include:

Mechanical wear (such as friction and wear of hoses, natural wear of pump components)

Improper maintenance (such as untimely oil replacement and failure to clean filters regularly)

Design defects (improper pipeline layout leading to air blockage)

Human operating errors (such as incorrect adjustment of pressure valves)

These reasons are often interrelated. For example, contamination accelerates wear, and wear leads to leakage and overheating, forming a vicious cycle.

Therefore, comprehensive prevention is required through regular oil testing, pressure testing and thermal imaging monitoring.

Solve the hydraulic system failure of the die casting machine

To solve the hydraulic system failure of the die-casting machine, it is necessary to combine the key components, common failure modes and maintenance methods of the hydraulic system.

The specific steps are as follows:

- Check the hydraulic oil status and pollution control

- Troubleshoot hydraulic pump and overflow valve failure

- Check the hydraulic pipeline and leakage points

- Verify system pressure and sensor feedback

Check the hydraulic oil status and pollution control

Pollution problem:

Hydraulic oil pollution is one of the main causes of Die Casting Machine Failures. It is necessary to monitor the oil quality regularly and determine whether it needs to be replaced or purified through visual inspection or oil analysis.

Filtration system maintenance

Ensure that the filtration system (such as filter element, filter screen) works properly and select appropriate filter media (such as high Beta ratio filter material) to remove particulate contaminants.

Oil tank cleaning

Hydraulic components must be strictly cleaned during maintenance to prevent external impurities from entering the system.

Troubleshoot hydraulic pump and overflow valve failure

Pump steering check

If the system has no pressure, first confirm whether the hydraulic pump steering is correct.

Overflow valve adjustment

Check whether the overflow valve causes pressure leakage due to jamming or improper adjustment. If the overflow valve is abnormal, it needs to be cleaned or replaced.

Pump performance test

Gradually isolate the hydraulic pump and test whether its output pressure is normal to eliminate the possibility of internal wear or damage to the pump.

Check the hydraulic pipeline and leakage points

External leakage

Check whether there is oil leakage in the pipeline, joints, and cylinder seals, and replace damaged seals or tighten joints in time.

Internal leakage:

Use pressure test to determine whether there is internal leakage in the valve or actuator (such as hydraulic cylinder), and repair or replace the faulty parts.

Verify system pressure and sensor feedback

Pressure instrument calibration

Use a pressure gauge or sensor to check whether the pressure at key nodes (such as pump outlet and actuator inlet) meets the set value.

For Die Casting Machine Failures,there are many other types, and we have extensive experience with them.

Please write to Haichen die casting machine for more details.