Like with any machine, safety and compliance with hot chamber die casting machines and compliance with safety regulations require the enforcement of safety measures, enforcement of machine protocols, machine care, and verification of compliance with the law for preservation of life and good quality production.

Serving as essential machinery for the manufacture of metal components, hot chamber die casting machines can rapidly produce and deliver components with exact specifications and consistently good quality.

Staff, however, need to ensure the equipment is use safely during every single step of use and all industry regulations are observe.

Compliance with the regulations is necessary to protect the safety of operators, to maintain uninterrupted assembly line function and avert incidents with the law.

The following is a detailed discussion of the safe operation of hot chamber die casting machines with regard to operation steps and compliance to rules.

Safety Considerations

- High Temperatures

- Molten Metal Handling

- Machine Guarding

- Emergency Procedures

- Air Quality and Ventilation

High Temperatures

The hot chamber die casting machines will require workers to follow strict safety protocols given the soot and fire that will be emitte during the die casting. Certain items of PPE that include face shields or gloves will need to be of fire resistant material and will need to be worn without fail.

Molten Metal Handling

Handling hot liquid metals involves some risk. Employees need to be train and follow strict rules. Employees need to monitor the situation and need to be active in maintaining safety so that contact with hot liquid metals is avoide.

Machine Guarding

The hot chamber die casting machines should be equip with features that keep the workers away from moving components. Operators need to check that the guards will need to be service regularly to ensure that the guards are functioning properly.

Emergency Procedures

All workers should know the basic emergency protocols, fire extinguishers, first aids and emergency stop buttons. Regular practice equip the workers to face the situations when the need arises.

Air Quality and Ventilation

Adequate hot chamber die casting machines, like any other machinery, can produce noticeable quantities of fumes and particulates. Hot chamber die casting machines are expected to produce an acceptable standard of air in the operator’s area of operation. The operators will require the use of breathing apparatus.

Compliance With Regulations

- Occupational Safety and Health Administration (OSHA)

- Environmental Protection Agency (EPA)

- Existing and Other Relevant Regulations

Occupational Safety and Health Administration (OSHA)

Every employer in the United States must follow OSHA guidelines to promote workplace safety. This involves the provision of PPE, safety training, and maintenance of the machinery.

Environmental Protection Agency (EPA)

Other relevant regulations may include emission and waste disposal for organizations that operate in hot chamber die casting. Compliance with these standards is a must; otherwise, organizations may face legal and financial consequences.

Existing and Other Relevant Regulations

Additional regulations may exist relative to a specific location. A business must ensure that they follow all relevant regulations in a particular jurisdiction, as this all helps promote business and legal standing in the industry.

Analysis of high-risk scenarios

- Mechanical injuries: extrusion of the clamping mechanism (accounting for 35% of accidents), entanglement of moving parts.

- Risks of molten metal:

- Nozzle splashing (a risk unique to hot chambers);

- Failure of the furnace cover seal leads to leakage of molten metal.

- Uncontrolled temperature rise: Excessive temperature in the hot chamber causes seal aging and metal oxidation. And the heat dissipation system needs to be monitored in real time.

Safety and Compliance with Hot Chamber Die Casting Machines

HAICHEN’s Safety and Compliance Practice for Hot Chamber Machines

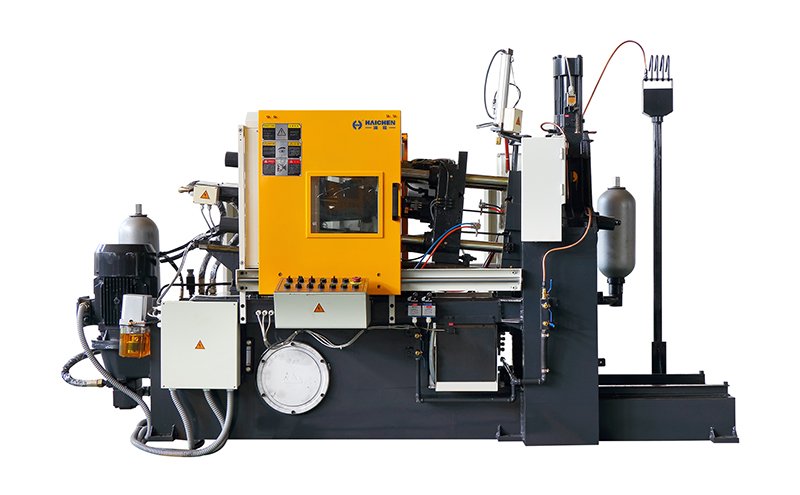

HAICHEN integrates safety and compliance requirements into the hardware and control systems of its hot chamber die casting machines, aiming to manage risks at the source and help customers establish a safe production environment.

- Integrated Proactive Safety Technology

- Precise Temperature Control and Process Safety Management

- Case Study: Safe Automated Production of Zinc Alloy Precision Parts

Integrated Proactive Safety Technology

Our machines come standard with protection systems meeting international safety standards (e.g., CE). Addressing the core risk of molten metal residing in the machine, we implement triple protection: the furnace has redundant level sensors and leak-proof seals; the nozzle area has non-contact temperature and flow monitoring to abort injection if abnormal; moving parts (like the clamp) are isolated by interlocked safety doors and light curtains, preventing access to hazardous areas.

Precise Temperature Control and Process Safety Management

Uncontrolled temperature is a key risk in hot chamber processing. HAICHEN machines use high-precision thermocouples and closed-loop control to limit temperature fluctuation in the furnace and gooseneck to within ±3°C, preventing metal oxidation or seal failure due to overheating. All safety-related signals (e.g., door limits, e-stop status) are connected to a dedicated safety PLC for millisecond-level monitoring and response, ensuring safety logic overrides any production command.

Case Study: Safe Automated Production of Zinc Alloy Precision Parts

A customer producing zinc alloy parts for smart locks faced burn risks from manual ladling and significant shop floor fumes on their old line.

- Challenge: To increase automation while eliminating molten metal exposure risks and improving the work environment.

- HAICHEN Solution: We supplied a hot chamber cell integrated with auto dosing and fume extraction. The machine features a fully enclosed furnace, with the mold connected only via the controlled injection channel. A side-draft hood was added to capture fumes directly at the nozzle.

- Result: “Hands-off” molten metal handling was achieved, completely eliminating manual contact risk. Airborne particulate concentration in the workshop dropped by over 70%, fully meeting occupational health standards. This safe and efficient cell became a key advantage for the customer in passing EHS (Environment, Health & Safety) audits from international brands.

List of safety protection equipment

| Protection category | Required equipment | Function |

| Mechanical protection | Interlocking safety door, electrosensitive protection equipment (GB/T 19436.1 Type 4) | Prevent limbs from entering the danger zone |

| Molten metal prevention and control | Liquid level sensor (redundant design), quantitative timeout shutdown device | Anti-overflow, anti-blocking |

| Temperature monitoring | Medium flow difference alarm device (magnesium alloy/large machine mandatory installation) | Prevent coolant leakage from causing explosion |

| Emergency control | Dual-circuit emergency stop system, accumulator safety valve | Rapid pressure relief shutdown when system fails |

It is important that hot chamber die casting machines are safe and in compliance with standards, as this helps protect workers, improve production efficiency, and avoid legal risks.

HAICHEN as a manufacturer must ensure that the equipment has a safety design integrated in the complete life cycle of the equipment and give customers compliance operation instructions to encourage the safety driven industry upgrade.

Compliance with safety and regulatory requirements helps manufacturers ensure a safe and productive workplace.