Die casting safety for high pressure die casting machines include machine guarding, personal protective equipment, proper ventilation, thorough operator training and regular maintenance.

High pressure die casting (HPDC) is one of the most flexible casting processes in manufacturing owing to its high speed, efficiency, and the ability to produce intricate features with great detail and accuracy. The systems that perform high-pressure die casting (HPDC) work with extreme pressure and temperature and therefore are a major safety concern if not properly controlled.

Consequently, there are a number of HPDC safety requirements that are key to ensuring safety of the operators while allowing productive cycle times.

In this article, we will describe what the safety requirements for high pressure die casting are, and how complying with these regulations can mitigate the dangers associated with it and ensure safety in the workplace.

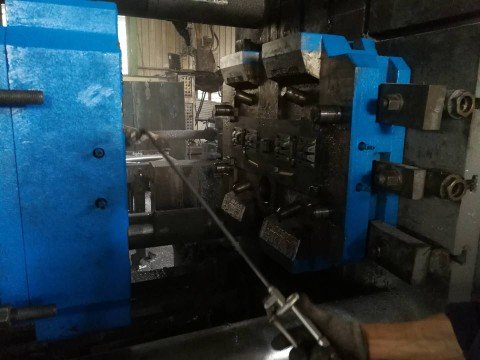

Machine Guarding and Enclosures

An integral part of injury prevention for HPDC equipment involves the addition of guarding and enclosures. Barriers should make it impossible for the operator to get access to moving parts, hot surfaces, and molten metal. Some specifications include:

- Guarding of Moving Parts

- Emergency Stop buttons

- Interlocked Safety Doors

Guarding of Moving Parts

All moving parts such as hydraulic actuators, plungers, and molds that are capable of being in contact with the operator should be enclosed.

Emergency Stop buttons

Put in place of easy reach emergency shut off switches at many points around the machinery so operators can swifly shut it off if it becomes necessary.

Interlocked Safety Doors

Interlocked safety doors which will isolate the machine from operating with the doors open should be fitted to the system. This ensures that operators cannot access the hazardous areas while the machine is in operation.

Personal Protective Equipment (PPE)

It is crucial for operators working with HPDC machines to put on protective personal gear to limit the risk of injury. The most important PPE includes:

- Heat-Resistant Gloves: Specialized gloves that protect hands from burns and metal splashes.

- Safety Eyewear: Use of spectacles or goggles to prevent eye injury from metal and other splashes or moving particles.

- Protective Clothing: Use of flame resistant coveralls, aprons or jackets for protection from spillage of hot metala and other heat sources.

- Safety Shoes: Footwear with protective steel caps to avoid toe injuries and splashes of hot molten metal.

Ventilation and Air Quality

Grinding, cutting, HPDC processes produce fumes and particulates that may be injurious to health when inhaled. Appropriate ventilation is necessary for maintaining the quality of air and workers’ health. Basic necessities are:

- Exhaust Systems: Expendible hoods and auxiliary ventilation should be installed in casting shops to collect. And evacuate fumes and particulates from the working area.

- Air Filtration: The use of air filtration measures is vital for the general health of workers to prevent inhalation of particulates.

Training and Certification

Operators must have comprehensive training and certification to operate HPDC machines. It is important that they give instruction on training programs such as:

- Machine Operation: Teaching the proper use of machine including its safe operation, starting, switching it off and emergency response actions.

- Hazard Awareness: Education on potential hazards associated with HPDC, such as high temperatures, high pressures, and molten metal.

- Safety Protocols: Regular training on workplace safety protocols and emergency response procedures.

Regular Maintenance and Inspections

To guarantee efficient and secure operation of HPDC machines, regular maintenance and inspections are necessary. These include:

- Scheduled Maintenance:Regular check-ups should be planned to maintain critical parts. Like the hydraulic system, mold clamping system, and safeties as well as fixing them when needed.

- Safety Inspections:Accident-related issues should be proactively taken care of through inspection.

High Pressure Die Casting Process

The high – pressure die casting process involves injecting molten metal into a mold cavity at high speed and under high pressure. This process requires precise control and careful handling to ensure both part quality and operator safety. Key steps in the HPDC process include:

- Metal Preparation

- Mold Preparation

- Injection

- Cooling and Solidification

- Part Ejection

Metal Preparation

The metal, typically aluminum or magnesium alloy, is melted in a furnace and transferred to the injection chamber. Proper temperature control is essential to ensure the metal is at the correct viscosity for injection.

Mold Preparation

The mold is cleaned and lubricated to prevent sticking and ensure smooth part ejection. The mold halves are then clamped together with high force to withstand the injection pressure.

Injection

The molten metal is injected into the mold cavity at high speed and under high pressure. This step requires precise control to ensure complete and uniform filling of the mold cavity.

Cooling and Solidification

The mold is cooled to solidify the metal. This step is critical to prevent defects and ensure part quality.

Part Ejection

The solidified part is ejected from the mold using ejector pins or plates. Proper ejection is essential to prevent part damage and ensure consistent production.

Die Casting Machine Manufacturer’s Commitment to High Pressure Die Casting Safety

Experts in manufacturing of die cast machines guarantees the safety and reliability of the design.

In protecting the operator and providing safe working conditions HAICHEN has incorporated important advanced safety features in its machines including:

- Advanced Safety Systems: These systems incorporate emergency stop buttons, interlocked safety doors, machine guarding. And others that establish HAICHEN machines as the most modern.

- User Friendly Interfaces: Hands-On Techniques Of HAICHEN’S Machines Interfaces allow operators to control and monitor the machine in a safe way. Operators are provided with easy to understand interfaces, thus making it user friendly.

- Regular Safety Training: Operators are provided with thorough training on machine operation. That cover every step including taking precautionary measures and hazard awareness.

Safety Best Practices from Industry Experience

One of HAICHEN’s clients that has been with them for a long time, a key supplier for automotive transmission components, has based their health and safety requirements on existing industry policies for active prevention of Incident Possibilities while ensuring HPH Die Casting Systems safety standards are met. Their safety measures stress the following:

Guarding of Machines

All die casting machines at the HAICHEN facility have interlocked safety doors that open only when the machine is not in operation.

Hazardous areas are fortified with light curtains as well as pressure sensitive mats.

Bathtub of Molten Metal

The automated pouring processes, which use elbows and hoses, decrease the amount of manual handling unit of molten zinc.

Splashes during ladling and injection are avoided by the use of thermal resistant barriers that shield operators.

Emergency Stop Systems

For immediate shutdown there are dual E-stop buttons situated at multiple operator stations.

furthermore, regular function testing ensures reliability.

Compliance Objectives and Training

Performance MDS – multiskilled operator instructor securities include mitor, assist, record and test snorkel drills

Fore supervisory, all participants are expose to safety training which is believe to be mandatory in the form of machine operation emergency drills.

HAICHEN Safety Technology and Practice

HAICHEN die casting machines build safety into their design and control systems. We use multiple layers of protection and smart monitoring to keep operators safe and production running.

- Layered Protection and Control System Integration

- Case Study: Helping a Customer Reach Zero-Incident Goals

Layered Protection and Control System Integration

Our machines use international-standard safety parts. These include dual-circuit interlock safety doors, emergency stop systems, and hard guards for dangerous areas. Safety logic is built into the PLC for constant self-checking and monitoring. Any problem causes an immediate safe stop.

Case Study: Helping a Customer Reach Zero-Incident Goals

A global auto parts supplier needed to meet a carmaker’s strict zero-incident safety rules.

- Challenge: Their old line’s safety protection was not strong enough. It lacked data tracking and struggled to pass audits under new safety standards.

- HAICHEN Solution: We supplied a die casting cell with a safety controller meeting Performance Level d (PLd). It included two-hand controls and full interlocked fencing. We activated the safety event logging feature and connected it to the customer’s MES system.

- Result: The new cell passed the carmaker’s safety audit. It had no recordable safety incidents in its first year. Safety check efficiency improved by 40%, and the data helped the customer manage safety better.

This manufacturer stated that there was a 40% decrease in safety incidents after using HAICHEN’s latest safety-enhanced die casting machines. They have shown that safely integrating advanced training and powerful features drives tremendous positive change in protection.

In conclusion, as with any machine, the operators’ safety and the general area where high pressure die casting machines are use needs to be take into consideration. Safety in die casting must be followe; the main requirements are guarding the machines, providing personal protective equipment, ventilation, thorough training, routine maintenance, and proper equipment will allow for the reduction in injuries and accidents greatly.