Selecting the right metallic lightweight materials requires a comprehensive analysis of material properties, cost, manufacturability, application requirements, and environmental impact.

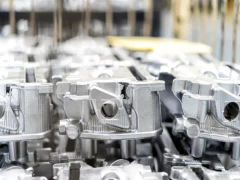

Lightweight metals constitute a category of materials characterised by high strength and low density, making them exceptionally well-suited for industries with stringent weight reduction requirements such as aerospace, automotive, medical, and defence. Haichen’s metal die-casting equipment is meticulously engineered to meet the performance demands of diverse products and the inherent properties of raw materials.

These metals enhance fuel efficiency, boost performance, and improve sustainability in advanced manufacturing applications. With the rise of metal additive manufacturing (AM) technology, these materials are being utilised to produce complex, high-performance components that optimise weight while ensuring durability.

Key points for selecting alloy materials for die casting production

- Core Material Properties Comparison

- Key Selection Criteria

- Decision-Making Workflow

Core Material Properties Comparison

- Aluminum (Al)

- Advantages:

- Density is one-third that of steel (~2.71 g/cm³), offering significant weight reduction.

- Excellent corrosion resistance, ideal for humid or corrosive environments.

- Lowest cost among lightweight metals, suitable for budget-sensitive projects.

- Superior formability via casting, extrusion, or rolling.

- Disadvantages:

- Lower strength compared to titanium and magnesium; requires alloying or structural reinforcement for high-load applications.

- Typical Applications: Automotive body panels, aerospace frames, electronics housings.

- Magnesium (Mg)

- Advantages:

- Lightest structural metal (1.74 g/cm³) with high specific strength.

- Ideal for thin-walled, complex geometries using vacuum die casting to minimize porosity.

- Disadvantages:

- Poor corrosion resistance, requiring surface treatments (e.g., Plasma Electrolytic Oxidation, PEO).

- Higher processing costs and flammability risks during machining.

- Typical Applications: Automotive dashboard brackets, lightweight portable devices.

- Titanium (Ti)

- Advantages:

- Highest strength (yield strength >1,000 MPa) and fatigue resistance.

- Exceptional corrosion and high-temperature resistance (>400°C).

- Disadvantages:

- Highest cost due to complex extraction and processing (e.g., thermomechanical processing, TMP).

- Difficult machining and forming.

- Typical Applications: Aerospace engines, medical implants, marine components.

Key Selection Criteria

Cost & Budget

- Titanium: Highest Metallic lightweight materials and processing costs; justified in high-value applications (e.g., aerospace).

- Magnesium: Moderate cost but requires surface treatments; balance lightweight benefits against processing expenses.

- Aluminum: Most cost-effective for mass production (e.g., automotive).

- Case Study: Automotive industries prioritize Al/Mg for cost efficiency, while aerospace favors Ti for performance.

Manufacturing & Processing

- Formability: Al offers the best formability; Mg requires vacuum die casting to avoid defects; Ti relies on TMP.

- Sheet Metal Forming (SMF): Al/Mg alloys are compatible with advanced SMF techniques; Ti demands specialized processes due to high hardness.

- Joining: Al/Mg allow welding/riveting; Ti welding requires inert gas shielding (e.g., TIG welding).

Sustainability

- Recyclability: Al and Mg achieve >90% recycling rates; Ti recycling is energy-intensive and less efficient.

- Carbon Footprint: Ti production emits 3–5× more CO₂ than Al/Mg; Al aligns better with net-zero goals.

Application-Specific Needs

- Aerospace: Prioritize Ti (strength, heat resistance) and Al (lightweight, cost).

- Automotive: Al (body structures) and Mg (interior components); Ti reserved for high-performance models.

- Electronics: Mg (lightweight, impact resistance) and Al (thermal conductivity).

Decision-Making Workflow

- Define Requirements: Load capacity, environmental conditions (corrosion, temperature), lifecycle durability.

- Cost Analysis: Include material, processing, surface treatment, and end-of-life recycling costs.

- Process Compatibility: Match material properties with manufacturing capabilities (e.g., casting, TMP).

- Sustainability Evaluation: Prioritize recyclable materials to comply with regulations (e.g., EU ELV Directive).

Emerging Trends

- Composites: CFRP (carbon fiber-reinforced polymer) offers lighter weight but higher costs; limited to niche applications.

- Advanced Alloys/Processes: Nano-modified Mg alloys and powder metallurgy enhance strength and reduce defects.

- Hybrid Material Designs: Combine steel, Al, and Mg to optimize local performance and cost.

Final Recommendations

- Choose Aluminum: For cost-effective, lightweight solutions with easy processing (e.g., automotive, consumer electronics).Metallic lightweight materials

- Choose Magnesium: For ultra-lightweight applications with moderate budgets (e.g., drones, racing components).

- Choose Titanium: For extreme performance in harsh environments (e.g., aerospace, biomedical).

Collaborate with material engineers and suppliers to validate choices through prototyping and testing.

Die casting lightweight metal materials

Common Lightweight Metal Materials in Die Casting

Aluminum, magnesium, and zinc alloys are widely used in die casting for lightweight applications, each offering unique advantages.

Below is an analysis of their properties and applications:

- Aluminum Alloys

- Magnesium Alloys

- Zinc Alloys

Aluminum Alloys

- Lightweight: Density ~2.7 g/cm³, ideal for reducing component weight.

- Key Advantages:

- High strength-to-weight ratio, excellent corrosion resistance, and thermal conductivity.

- Alloys like ADC12 (with Si, Cu, Mg) enhance mechanical properties and castability.

- Applications:

- Automotive: Engine brackets, transmission housings, and hydraulic components.

- Aerospace: Sensor housings, structural parts for fuel efficiency.

- Electronics: Precision components (e.g., laptop frames) due to dimensional stability.

Magnesium Alloys

- Ultra-Lightweight: Density ~1.74 g/cm³ (36% lighter than aluminum).

- Key Advantages:

- Exceptional strength-to-weight ratio, shock absorption, and recyclability.

- Ideal for thin-walled, complex geometries.

- Applications:

- Automotive: Gearbox cases, seat frames (e.g., 35% weight reduction in some models).

- Aerospace: High-load components (e.g., drone parts).

- Limitations: Higher cost and lower thermal stability vs. aluminum.

Zinc Alloys

- Moderate Weight: Density ~7.1 g/cm³ (lighter than steel, heavier than Al/Mg).

- Key Advantages:

- High precision, low melting point, and excellent surface finish.

- Cost-effective for small, intricate parts.

- Applications:

- Automotive: Non-structural parts (e.g., AC components, connectors).

- Electronics: Decorative housings, connectors.

Material Selection Factors

- Design Requirements: Aluminum/magnesium for high-strength parts; zinc for aesthetics.

- Production Constraints: Magnesium requires inert gas handling (flammable).

- Supply Chain: Availability of specialized alloys (e.g., rare earth-enhanced Mg).

Future Trends

- Advanced Processes: Vacuum die casting to reduce porosity in magnesium.

- Hybrid Materials: Combining alloys with polymers for weight savings.

- Sustainable Practices: Recyclable alloys and energy-efficient die designs.

In summary, aluminum alloys take up the major share of mainstream applications whereas magnesium is good for application in extreme lightweighting and zinc fits high-precision, low-cost applications. The choice varies with a comparison between performance, cost, and manufacturability.

Rewrite this email to learn more about the technical support for metal die casting processing from Haichen.