Selection criteria for high pressure die casting machine have several factors:

- Other Considerations

- Technical Parameters and Process Requirements

- Material Selection

- Equipment Performance and Stability

- Economic and Efficiency Considerations

- Environmental and Sustainability Factors

By carefully evaluating these criteria, you can select a high-pressure die casting machine that meets your production needs and ensures high-quality castings.

Because high pressure die casting sounds straightforward until you face real production challenges.

You deal with complex defects, unpredictable cycle times, and quality issues that cost thousands in scrap and delays.

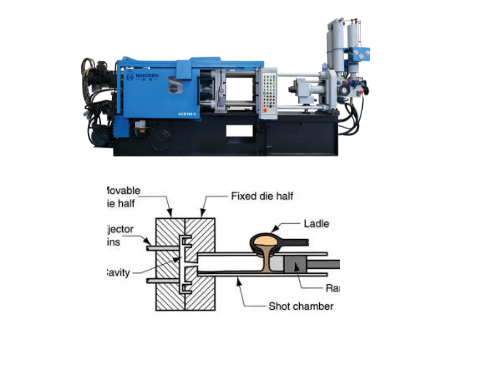

High pressure die casting is a metal forming process that injects molten metal into steel dies under extreme pressure, creating precise, near-net-shape parts with excellent surface finish and dimensional accuracy.

Haichen will assist you in resolving issues, optimizing processes, and making data-driven decisions, thereby enhancing your production outcomes.

What is High Pressure Die Casting Machine?

A high-pressure die casting machine is an industrial equipment used for large-scale production of complex metal parts.

Forming high-precision, thin-walled castings by injecting molten metal into reusable steel molds under high pressure.

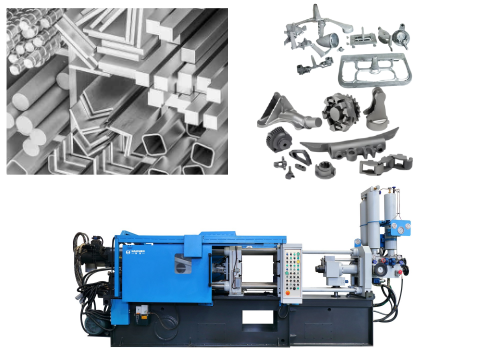

This process is known for its high production efficiency, excellent dimensional accuracy.

And surface quality, and is widely used in industries such as automotive, aerospace, electronics, and plumbing.

Haichen has a professional engineering team for the production of high-pressure die casting machines.

If you need more information, please contact us.

High-pressure die-casting machine machine type

- Hot-chamber machine

- Cold-Chamber Machine

Hot-chamber machine:

Haichen’s high-pressure hot-chamber die-casting machines are suitable for low-melting-point alloys such as zinc, tin, lead, and some magnesium alloys.

Where the metal remains molten inside the machine, and the injection unit is directly immersed in the furnace.

The advantages are short cycle times and high efficiency, but they are limited to materials with low melting points.

Cold-Chamber Machine:

The Haichen cold chamber die-casting machine has been meticulously designed to ensure that the dimensions of the castings are precisely consistent, thereby producing high-quality parts.

Suitable for high melting point alloys such as aluminum and copper alloys, molten metal is scooped from an external furnace into an incidence sleeve, and then injected.

The advantage is that it can handle materials with higher temperatures, but with slightly longer cycles.

Selection Criteria for High Pressure Die Casting Machine

- Technical Parameters and Process Requirements

- Material Selection

- Equipment Performance and Stability

- Economic and Efficiency Considerations

- Environmental and Sustainability Factors

- Other Considerations

Technical Parameters and Process Requirements

Injection Pressure: High-pressure die casting requires high injection pressure to ensure that the molten metal completely fills the mold cavity and overcomes the resistance of gases.

For example, aluminum die casting typically requires an injection pressure of 90 MPa.

Mold Design: The design of the mold directly affects the quality of the die-casting parts and production efficiency.

The mold needs to have an effective cooling system to shorten cycle times and ensure that the mold material can withstand high temperatures and pressures.

Chamber Capacity and Locking Force: The chamber capacity must meet production requirements.

While the locking force must exceed the product of the injection pressure and the projected area to prevent mold cracking or flash formation.

Material Selection

Alloy Type: Different alloys have distinct performance characteristics.

For example, aluminum, zinc, and magnesium alloys are suitable for cold chamber die casting.

While copper and lead-based alloys are appropriate for hot chamber die casting.

Sustainability and Cost-Effectiveness: When selecting materials, it is necessary to balance quality, cost, and environmental impact.

For instance, although zinc alloy is more expensive, its superior properties make it more attractive in certain applications.

Equipment Performance and Stability

Mechanical Performance: The selected die-casting machine should feature high precision, high rigidity, and low maintenance frequency.

For example, the HDC series cold chamber die-casting machines improve equipment stability and reliability by optimizing the hydraulic system and injection unit design.

Operational Safety: The equipment should be equipped with safety devices, such as hydraulic safety valves and emergency stop buttons, to ensure the safety of operators.

Intelligent and Automated Features: Modern die-casting machines typically come with real-time monitoring systems and intelligent quality management systems that can automatically detect and reject defective products, thereby improving production efficiency.

Economic and Efficiency Considerations

Production Efficiency: High-pressure die-casting machines should have the ability to fill and cool quickly to shorten production cycles and increase output.

For example, optimizing process parameters (such as injection speed and holding time) can significantly enhance production efficiency.

Maintenance Costs: The maintenance costs of the equipment are also an important factor in selection. For instance, HTS offers a full-system service, including maintenance of the injection plunger, oil circuit, and ring heaters, which helps reduce long-term operating costs.

Environmental and Sustainability Factors

Energy Efficiency: Since die-casting is a high-energy-consuming process, selecting energy-efficient equipment can reduce production costs and minimize environmental impact.

Material Recycling and Reuse: Choosing equipment and processes that support material recycling and reuse helps achieve sustainable development goals.

Other Considerations

Supplier Support and After-Sales Service: When selecting equipment, it is crucial to consider the supplier’s technical support capabilities and the quality of after-sales service. For example, suppliers should offer at least a 5-year warranty and have a comprehensive training and technical support system in place.

Customization Needs: For complex parts or special applications, customized equipment or specialized functional modules may be required, such as high-flow quick-change valves or high-performance servo motors.

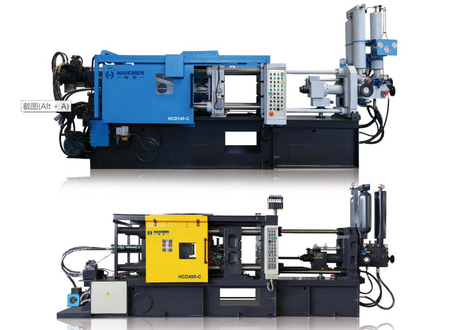

High Pressure Die Casting Machine supplier: Haichen Machinery

Haichen Machinery is a Chinese company specializing in the manufacturing and supply of high pressure cold chamber die casting machines, hot chamber die casting machines and related equipment. We offer a range of die-casting solutions, particularly for aluminum, magnesium, and zinc alloys.

Selection of high-pressure die-casting machine need to consider the technical parameters, material characteristics, equipment performance, economy, environmental impact and supplier support and so on many aspects.

Through scientific evaluation and rational decision-making, can ensure that the selected equipment can meet the production demand and realize the high efficiency, high quality production target.