In the die-casting process, Connecting Rods are key connecting components, mainly used to transmit motion forces and withstand high loads.

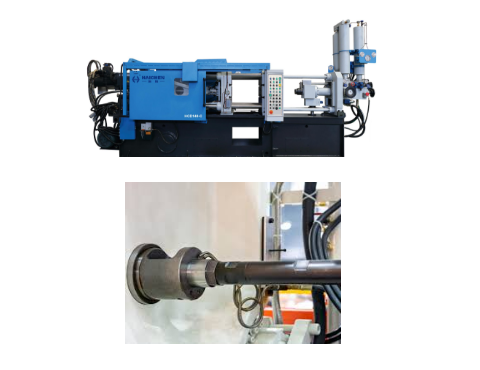

For instance, they connect the injection rod and the hammer head in the injection system of a die-casting machine, or the piston and the crankshaft in an engine.

Connecting rods in die casting needs to integrate material properties, process parameters, application scenarios.

And industry standards, and balance performance and cost through optimized design and quality control.

What Is Connecting Rod?

The connecting rod, often referred to as the “common rod”, is a crucial component in the Haichen die-casting machine.

The connecting rod plays a role in transmitting force and motion in the die-casting machine, converting the rotational motion of the drive system into the linear motion required for injection, ensuring the smooth progress of the die-casting process.

As a key structural component, the connecting rod needs to withstand high pressure and cyclic stress, and the material must have sufficient strength and toughness.

The connecting rod type of the Haichen die-casting machine

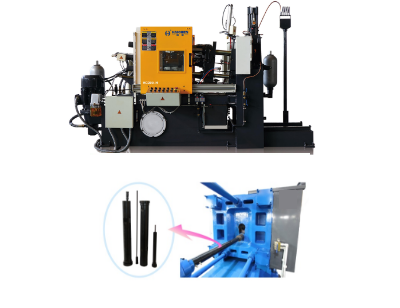

- Quenched and tempered steel connecting rod

- Non-quenched and tempered steel connecting rod

Quenched and tempered steel connecting rods refer to connecting rods that, after being forged, need to undergo quenching and high-temperature tempering treatment to ultimately meet the performance requirements.

Non-quenched steel connecting rods refer to connecting rods that are forged and then cooled at a controlled rate after forging to meet the performance requirements.

Connecting rods in die casting commonly used die-casting materials

- Aluminum alloy

- Magnesium alloy

- Zinc alloy

- High-strength titanium alloy

- Powder metallurgy materials

Aluminum alloy

Lightweight preferred (density 2.7g/cm³), high mechanical strength (tensile strength 245-371MPa).

Excellent thermal/electrical conductivity, good high temperature resistance, suitable for automotive engines, new energy battery shells and other scenarios.

Typical grades include ADC12 (extrusion casting tensile strength 371 MPa and elongation 7.1%).

Magnesium alloy

The lightest die-cast metal (density 1.8g/cm³), suitable for 3C products and lightweight automotive parts, but sensitive to corrosion and requiring surface treatment.

Zinc alloy

Easy die-casting (melting point 385°C), high toughness (impact strength >100J/cm²), excellent electroplating performance, mostly used in small mechanical parts and low-load scenarios.

High-strength titanium alloy

Density 4.5g/cm³ (40% lighter than steel), tensile strength 900-1200MPa, insensitive to stress concentration, suitable for aviation and high-end racing engines.

Powder metallurgy materials

Such as Fe-0.5C-2.0Cu alloy, density 7.2g/cm³, fatigue performance close to forged steel, cost reduction of 15%-20%.

The choice of materials will affect the strength, weight and cost of the connecting rod. When selecting materials.

Haichen will take into account the type of die-casting machine, expected performance and load conditions.

Core Design Parameter Specifications

- Mechanical property index

- Geometric accuracy requirements

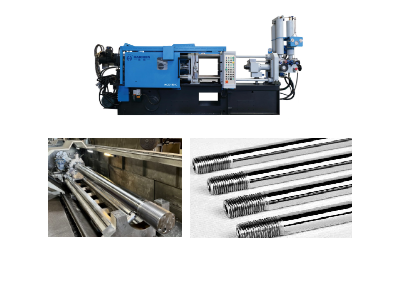

Mechanical property index

Tensile strength: aluminum alloy die-casting ≥ 245MPa (conventional die-casting), extrusion casting up to 371MPa.

Fatigue strength: The ductile iron connecting rod needs to be ≥ 300N/mm², and it will be increased by 30%-50% after shot peening.

Hardness control: cast iron HB210-250, steel connecting rod HB223-280, the hardness difference of the same group connecting rod ≤ 40HB.

Geometric accuracy requirements

Hole position accuracy: After multi-station machine tool processing, the hole distance tolerance is ±0.025mm, and the hole cylindricity is ≤ 2.5μm.

Flatness: The flatness of the end face of the big head hole is ≤0.1mm, and the flash height of the parting surface is ≤0.8mm.

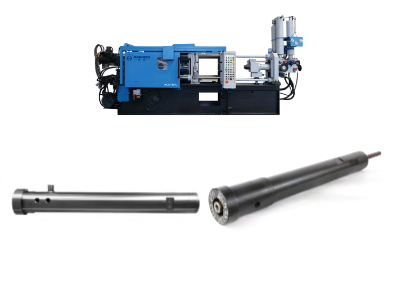

Lightweighting and structural optimization

- Quality matching

- Finite element analysis

Quality matching

The weight difference of the paired connecting rods is ≤8g, and the weight of the aluminum alloy connecting rods is reduced by 60%-70% compared with steel.

Finite element analysis

Multi-body dynamics is used to optimize the cross-sectional shape of the rod and increase the bearing area by 20%-30%.

Industry standards and quality control

The steel connecting rod shall comply with GB/T 699 (45 steel) or GB/T 3077 (40Cr, etc.).

With a hardness of 230~320HBW, and the hardness difference of the same group ≤35HBW.

Aluminum alloy die castings need to meet the tensile strength of ≥ 245MPa and the elongation of ≥2%.

Testing requirements

- Non-destructive testing

- Cleanliness

- Common failure modes

Non-destructive testing

Magnetic particle testing (JB/T 6721.2) to check for cracks/folding, X-ray (ASTM E446) to detect internal shrinkage.

Cleanliness

Control the content of impurities according to GB/T 3821 standard to avoid blockage of lubricating oil channels.

Common failure modes

Fatigue fracture

Optimization of material tensile strength and surface reinforcement (e.g., shot peening).

Error/trimming and stretching

Improve the mold locking structure and optimize the ejection mechanism to reduce deformation.

Future development trend

- Lightweight

- Intelligent manufacturing

- Green process

Lightweight

Titanium alloy/carbon fiber composite material application, combined with topology optimization design to further reduce weight.

Intelligent manufacturing

High-precision multi-station machine tools (hole line parallelism 0.02/100mm) and AI process optimization to improve yield.

Green process

Promote semi-solid squeeze casting, reduce energy consumption and defect rate, and adapt to the goal of carbon neutrality.