Shrinkage defects are those cavities inside the parts that reduce strength; if they are on the surface, they reduce aesthetics and corrosion resistance. It is also very important to be able to differentiate between shrinkage cavities and gas bubbles: cavities from gas bubbles are always round, whereas shrinkage cavities due to lack of material have a very sharply defined surface. The size and shape of the cavity, as well as what its surface looks like.

Distinguishing shrinkage cavities from gas bubbles is also crucial: cavities caused by gas bubbles appear circular, whereas shrinkage cavities resulting from insufficient material exhibit sharply defined surfaces.

Identifying the size, shape, and surface characteristics of cavities is essential for recognising defect types and determining their causes.

The manifestation and control measures of aluminum alloy die casting Shrinkage porosity

- Definition and Causes

- Detection Methods

- Prevention and Solutions

- Additional Considerations

- Key Takeaways

Definition and Causes

Shrinkage porosity refers to voids or pores formed in a die-cast part due to inadequate compensation for metal contraction during solidification. Key causes include:

- Inadequate Feeding: Poor gating/runner design or premature freezing of gates, preventing sufficient molten metal from reaching shrinking areas.

- Process Parameters: Insufficient holding pressure or time, incorrect injection speeds, or suboptimal temperatures (molten metal and die).

- Alloy Characteristics: Metals with high shrinkage rates (e.g., aluminum alloys) are more prone.

- Part Geometry: Thick sections solidify last, creating isolated pools if not properly fed.

- Cooling Inconsistencies: Non-uniform die cooling leads to varied solidification rates.

Detection Methods

- Non-Destructive Testing (NDT): X-ray, CT scans, and ultrasonic inspection identify internal voids.

- Destructive Testing: Sectioning parts to visually inspect porosity.

Prevention and Solutions

- Mold Design Optimization:

- Ensure proper gate/runner sizing and placement to maintain feeding until solidification.

- Use simulation software to predict shrinkage and adjust designs (e.g., adding ribs, reducing thick sections).

- Implement controlled cooling channels for uniform solidification.

- Process Adjustments:

- Increase holding pressure/time to enhance feeding during solidification.

- Optimize injection speed and temperature profiles (molten metal and die).

- Consider multi-stage injection to maintain pressure post-filling.

- Material Selection: Use alloys with lower shrinkage tendencies (e.g., zinc alloys over aluminum).

- Post-Processing: Apply Hot Isostatic Pressing (HIP) to close voids, though this adds cost.

Additional Considerations

- Vacuum Die Casting: Reduces gas porosity, indirectly aiding shrinkage management by improving pressure effectiveness.

- Part Design: Simplify geometries, avoid abrupt thickness changes, and use simulations to guide modifications.

Key Takeaways

Shrinkage porosity arises from interplay between material properties, process parameters, and design. Mitigation requires a holistic approach combining optimized mold design, precise process control, and strategic material selection. Advanced simulations and NDT are critical for proactive detection and resolution.

How to reduce porosity in die casting?

To reduce porosity in die casting, a systematic approach involving design optimization, process control, material selection, and auxiliary technologies is required. Below are detailed strategies:

- Design Stage Optimization

- Process Parameter Control

- Mold Cooling and Lubrication

- Additional Critical Measures

- Case Studies & Validation

Design Stage Optimization

- Mold Design and Simulation

- Use simulation software (e.g., MAGMA, Flow-3D) to analyze metal flow and optimize gate systems, overflow channels, cooling channels, and vents. Adjust runner designs to minimize turbulence and gas entrapment.

- Position overflow wells and vents strategically in critical areas to evacuate trapped gases.

- Haichen is exceptional in its attention to detail in mold structure, runners, and internal mechanisms.

- Vacuum-Assisted Die Casting (VPDC)

- Employ vacuum systems to evacuate air from the mold cavity before injection. Studies show VPDC reduces porosity by 24.4% on average, with porosity decreasing by 57% at 70 mbar vacuum levels.

- Vacuums also remove gas residues from mold lubricants, preventing pore formation during solidification.

Process Parameter Control

- Injection Speed and Pressure

- Reduce injection speed to minimize turbulence-induced gas entrapment, but balance with solidification front formation.

- Increase holding pressure to compensate for shrinkage and reduce shrinkage porosity.

- Temperature and Material Management

- Maintain optimal melt temperature: Excessive heat increases gas solubility, while low temperatures cause premature solidification.

- Use high-purity alloys and degassing agents (e.g., argon purging) to remove dissolved gases during melting.

Mold Cooling and Lubrication

- Integrate cooling channels (e.g., in core pins) to control solidification rates, redirecting porosity to non-critical areas and reducing pore density.

- Minimize lubricant application to avoid excessive gas generation from vaporization.

Additional Critical Measures

- Early Collaboration and Testing

- Collaborate with engineers during design-for-manufacturability (DFM) to identify porosity-prone zones. Optimize part geometry (e.g., uniform wall thickness, rounded corners).

- Use X-ray, CT scans, or microscopy to detect porosity and adjust processes accordingly.

- Mold Maintenance and Process Monitoring

- Regularly maintain equipment to ensure consistent pressure and temperature stability.

- Apply vacuum impregnation (e.g., secondary impregnation) to seal unavoidable micro-pores in critical components.

Case Studies & Validation

- Copper Rotor Die Casting: Simulation-guided optimization reduced porosity from 25% to 8–10%.

- Aluminum Alloy (AlSi9Cu3): VPDC increased tensile strength by 10% and elongation by 50% compared to conventional die casting.

Reducing porosity demands a holistic strategy:

- Design: Simulation and vacuum systems are key.

- Process: Fine-tune injection parameters, temperature, and pressure.

- Materials: Use high-quality alloys and degassing techniques.

- Validation: Leverage testing and real-time monitoring for continuous improvement.

By combining these methods, porosity can be systematically minimized while enhancing mechanical properties and part reliability.

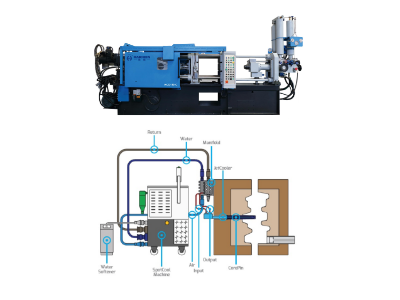

Haichen die casting machine can help you solve the porosity problem in production

Haichen Die Casting Machines Address Porosity Issues with Advanced Solutions:

- Precursive Injection Control Technology

- Enhanced Mold Clamping Stability

- Servo-Driven Intelligent Control

- Mold Design Integration & Process Support

- Energy Efficiency & Process Consistency

Precursive Injection Control Technology

Haichen’s C-series cold chamber die casting machines utilize magnetic ruler-controlled four-stage injection positioning, directly regulated via computer PLC. This precision ensures optimized injection speed and pressure switching points, minimizing turbulence and gas entrapment during mold filling. For instance, adjusting high-speed switching points and injection pressure ratios reduces gas entrapment), aligning with process parameter optimization requirements.

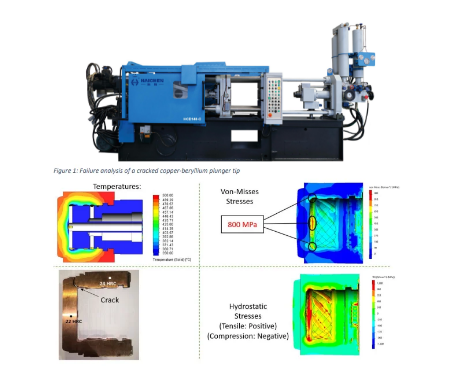

Enhanced Mold Clamping Stability

The inclined five-point toggle clamping mechanism outperforms traditional straight-row designs by offering higher clamping force and stability. Finite element analysis (FEA) optimizes stress distribution on templates and critical components, ensuring mold closure accuracy. This reduces gas retention caused by mold deformation or poor venting, complementing mold thermal management and runner design principles.

Servo-Driven Intelligent Control

Haichen’s next-gen machines integrate servo systems and smart PLCs for real-time process visualization and parameter precision. The servo system dynamically adjusts injection speed and intensification time to suppress turbulence (a key porosity trigger). PLCs support multi-language interfaces and mold parameter storage, enabling rapid optimization for diverse products.

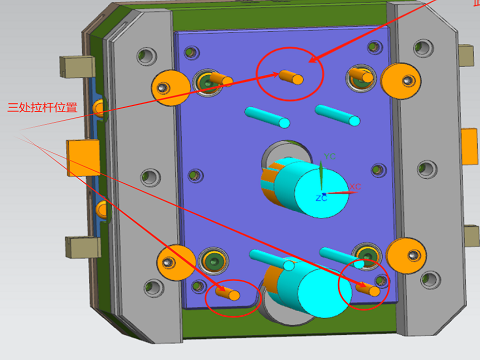

Mold Design Integration & Process Support

Haichen provides end-to-end solutions from mold design to machine configuration. Techniques include:

- Extending sprue/runner lengths (>50mm) to enhance gas escape.

- Adding overflow/vent channels (as referenced in technical guidelines).

- High-pressure spot cooling systems to stabilize mold temperatures and mitigate gas pressure effects.

Energy Efficiency & Process Consistency

Energy-saving designs reduce thermal fluctuations, preventing excessive mold temperatures that exacerbate gas (outgassing). High machine stability and low failure rates (comparable to industry leaders ) ensure parameter consistency, minimizing porosity from process variations.

By the end

While Haichen’s machines may not explicitly incorporate vacuum-assisted die casting (e.g., HCD400-C vacuum feature), their precision injection control, robust clamping, intelligent process management, and mold design collaboration systematically address porosity root causes (gas entrapment, venting inefficiency, parameter mismatch). Users can leverage these solutions for targeted improvements, achieving higher-quality castings with reduced defect rates.

Contact Haichen via e-mail anytime for more Die Casting Technical Support.