Die-cast parts sulotion

Haichen like to share the sulotion for Aluminium die casting, Zinc die casting, Lead die casting sulotions.

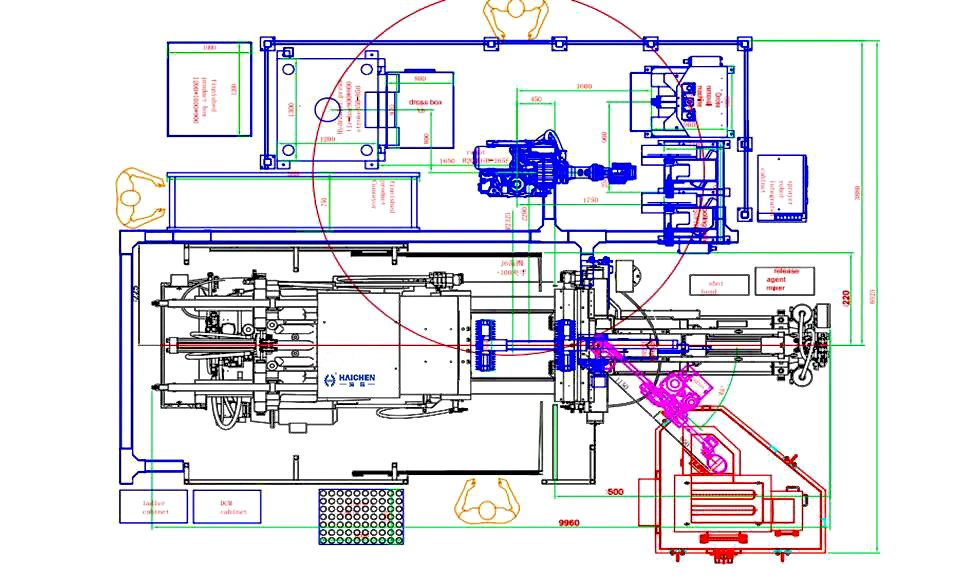

We will try to explain the production line in details, from the alloy material to die casting, die casting mold, fine machining, printing, till to packing. Including the whole production line of alloy casting parts, as the die casting example.

We’d like to explain the die casting solutions, to fix the problem during you useing the die casting machines.

Die Casting Aluminium Radiators

The die-casting process of aluminum alloy radiator is an efficient metal forming technology, which uses high pressure and high-speed force to press the melted aluminum alloy into the radiator mold, and then cools it to form solid metal parts. This process is particularly suitable for mass production of components with high precision, repeatability, and high surface finish.

In the production process of aluminum alloy radiators, the first step is to purchase raw materials aluminum. Then, these aluminum are melted in the furnace which at side of cold chamber die casting machine. Next, the molten aluminum alloy is pressed into the rediator mold under high pressure. In the mold, aluminum alloy fills the cavity under high pressure and high speed, and rapidly cools to form the final casting- radiator heater.

Zinc alloy medal, alloy coins die casting

Zinc alloy die casting is an efficient metal forming process widely used in the manufacture of metal crafts such as medals,badges,coins. Zinc alloy has become an ideal material for making medals due to its excellent casting performance and surface treatment ability.

The zinc alloy die-casting process involves injecting molten zinc alloy into a medal mold, filling the cavity with high pressure and speed, and then rapidly cooling to form a Zinc medal. This process can produce castings with complex shapes, thin walls, and high precision, with smooth surfaces and rich details.

Zinc alloy die cast medals typically have highly polished surfaces and smooth textures, making them suitable for creating badges and medals with intricate patterns and prominent three-dimensional effects. In addition, zinc alloy die-casting medals can further enhance their aesthetics and durability through various surface treatment processes such as electroplating and painting.

The production process of zinc alloy die-casting medals includes steps such as melting zinc alloy, injection molding, cooling molding, machining, and surface treatment. In the production process, it is usually necessary to spray release agent on the mold to facilitate demolding, and then polish and spray paint in subsequent steps.

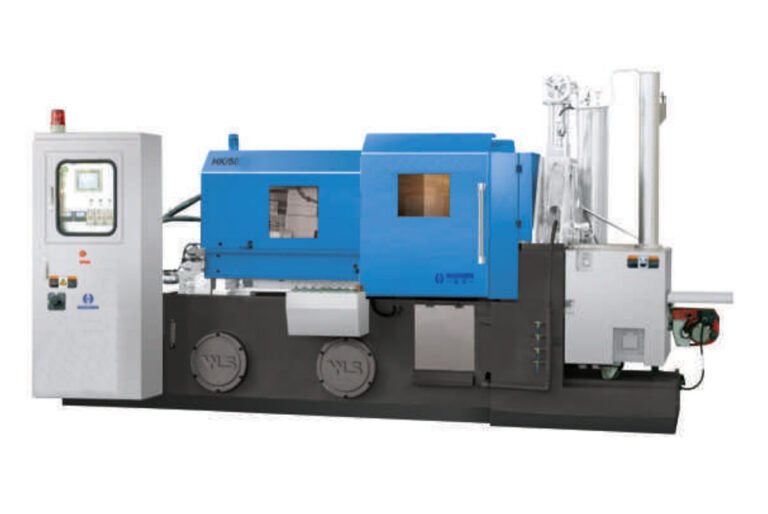

Haichen die casting machine

Haichen is the manufacturer of die casting machine, including cold chamber and hot chamber die casting machine.