Stainless steel alloy casting services are typically used for the production of die-casting molds.

It performs well in liquid environments and provides heat resistance at high temperatures. There are numerous types of stainless steel and each contains a different chemical composition.

The composition affects mechanical properties and determines whether the material can be further strengthened through heat treatment.

For investment casting applications requiring corrosion resistance and high strength, stainless steel casting is an ideal choice.

People use the stainless steel investment casting process to create components for a range of industries including aerospace, petrochemical, medical, automotive, and food and dairy.

Some of the parts and components commonly produced through stainless steel casting include:

Stainless steel alloy casting services are a manufacturing process by injecting molten stainless steel alloy into a mold and cooling it into precision parts.

Stainless Steel Alloy Casting Types

- Corrosion-resistant castings (C series)

- Heat-resistant castings (H series)

Corrosion-resistant castings (C series)

Carbon content ≤ 0.08% (such as CF-8M), suitable for chemical, marine and other corrosive environments.

Corrosion-Resistant Castings (C series for short) is a core category in stainless steel alloy casting.

Which is designed for long-term stable operation in corrosive environments.

Heat-resistant castings (H series)

We design Heat-Resistant Castings (H series) for high-temperature environments (typically > 650°C).

They have excellent oxidation, creep and thermal fatigue resistance, and we widely use them in petrochemical, energy and heat treatment equipment.

Carbon content up to 0.75% (e.g. HK-40) for high temperature environments (>650°C) such as boiler components.

The classification system uses the American Iron and Steel Foundry Association (SFSA) nomenclature convention, e.g. CF-8M denotes a 19Cr-9Ni type corrosion-resistant alloy containing molybdenum.

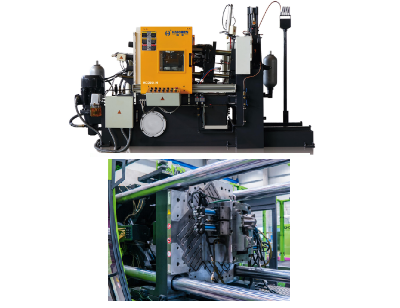

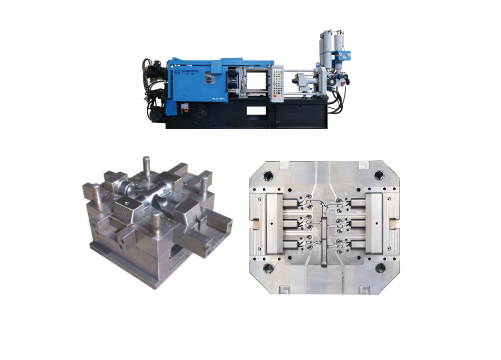

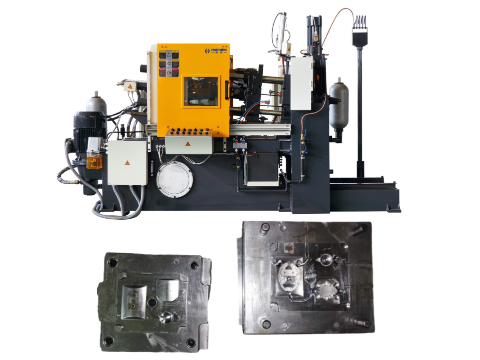

Stainless Steel Alloy Casting Molds

As a manufacturer of die-casting machines and related molds, Haichen attach great importance to customer satisfaction and excellent customer service.

We take high-quality customer service, supply capacity, highly competitive prices, fast delivery cycles and an experienced workforce as the foundation to ensure product quality.

Our success in the steel casting die-casting mold industry stems from our possession of exquisite technology, our full participation in the project, and our maintaining good communication with customers during the casting process.

Our professional team will work closely with customers. By understanding their goals and offering improvement suggestions, we will help them create high-quality molds without sacrificing quality and performance.

Key points of the manufacturing process

- Melt control

- Casting process

- Post-processing

Melt control

AOD/VOD refining is used to ensure ultra-low carbon (C≤0.03%) and reduce Cr carbide precipitation.

The oxygen activity at the end of smelting is ≤5ppm to avoid oxide inclusions.

Casting process

Investment casting: suitable for complex thin-walled parts (e.g. valve cavities) with a surface accuracy of CT6 (ISO 8062).

Sand casting: Large castings (such as pump bodies) need to use chromite to prevent metal-mold reactions.

Post-processing

Solution treatment: 1050-1100°C water quenching to dissolve carbides and restore austenite homogeneity.

Pickling passivation: Nitric acid and hydrofluoric acid mixture removes the oxide scale and activates the passivation membrane.

The production process of stainless steel alloy casting

- Raw material preparation

- Smelting

- Refining

- Pouring

- Cooling & Post-Processing

- Heat treatment

- Finished product inspection and packaging

Raw material preparation

According to the product requirements, select the appropriate stainless steel alloy composition.

And prepare scrap steel, ferroalloys (such as ferrochrome, ferronickel) and other raw materials.

Smelting

First, we heat the raw material to 1480°C–1500°C in an electric arc furnace or induction furnace to form liquid metal.

Then, during the melting process, we add desulfurizers, slag removers, etc., to remove impurities and stabilize the ingredients.

Finally, as needed, we perform decarburization, oxidation, reduction alloying, etc.

Refining

Vacuum degassing methods such as VOD or LF furnaces are used to further remove gaseous.

And non-metallic inclusions and improve the quality of the molten steel.

Residue washing or secondary refining may be performed to optimize composition and performance.

Pouring

Molten stainless steel liquid is poured into the mold, cooled and solidified to form a casting.

It should be noted that defects such as porosity and cracks should be prevented during the pouring process.

Cooling & Post-Processing

After the casting cools, we remove it by mechanical crushing or hydraulics.

We carry out surface treatments such as grinding, cutting, and shot blasting on castings to remove excess material and clean up surface defects.

Heat treatment

According to the demand, the castings are subjected to heat treatment processes such as annealing, quenching.

And tempering to improve their mechanical properties and corrosion resistance.

Finished product inspection and packaging

Finally, the quality inspection of the finished product is carried out to ensure that it meets the technical requirements and packaging.

Common material types and performance parameters of stainless steel alloy casting

- Austenitic stainless steel

- Ferritic stainless steel

- Martensitic stainless steel

- Duplex stainless steel

The types of materials commonly used in stainless steel alloy casting mainly include austenitic, ferritic, martensitic and duplex stainless steels.

Which have different chemical compositions and performance characteristics and are suitable for a variety of industrial fields.

Austenitic stainless steel

Common grades: 304, 316, 308, 310, etc.

Characteristics: High chromium content (usually more than 18%), high nickel content, good corrosion resistance and ductility, but low mechanical strength.

Application: Widely used in food processing equipment, chemical equipment, building decoration and other fields.

Ferritic stainless steel

Common grades: 201, 409, etc.

Features: High chromium content (about 12%-17%), nickel-free or low nickel content, lower cost.

But poor corrosion resistance and mechanical strength.

Application: Suitable for low requirements of corrosion-resistant environments.

Such as automobile exhaust systems, building structures, etc.

Martensitic stainless steel

Common grades: 410, 420, 17-4PH, etc.

Features: High chromium content (about 11%-25%), high carbon content, good strength and hardness, but poor corrosion resistance.

Application: Suitable for parts that require high strength and wear resistance, such as knives, springs, mechanical parts, etc.

Duplex stainless steel

Common grades: 321, 347, 2205, etc.

Features: Combining the advantages of austenite and ferrite, it has high strength and good corrosion resistance, especially strong resistance to pitting and crevice corrosion.

Application: Suitable for chemical equipment, marine engineering, food processing and other fields.

Precipitation hardening stainless steel

Features: Strength and corrosion resistance are improved by adding alloying elements.

Such as molybdenum, titanium, but it is difficult to process.

Application: Used in high-end fields such as aerospace and nuclear industry.

Effect of different casting methods on the properties of stainless steel alloys

- Sand casting

- Precision casting

- Investment Casting

- Pressure casting

- Other methods

Sand casting

Advantages: low cost, strong adaptability, suitable for mass production, molds are simple and easy to make, and products with complex shapes can be manufactured.

It is suitable for single-piece, small-batch manual molding and batch, large-scale machine molding production.

Disadvantages: The surface roughness of the casting is high, and it is easy to have defects.

Such as porosity and slag inclusion, which affects the mechanical properties and surface quality of the casting.

In addition, due to the slow cooling rate of the sand mold, it can lead to coarse grains and reduce the mechanical properties of the material.

Precision casting

Advantages: The casting has high precision and good surface quality.

Which is suitable for precision parts with complex shapes, especially for high-end products.

By controlling the casting process, such as risers, cold iron, subsidies and other measures, defects.

Such as shrinkage porosity and shrinkage porosity can be effectively reduced.

Disadvantages: the cost is high, the process is complex, the technical requirements are high, and the material fluidity requirements are high.

And the fluidity of stainless steel is poor, so special attention needs to be paid to the pouring temperature and process parameters.

Investment Casting

Advantages: It is suitable for manufacturing castings with complex shapes and high precision, with smooth surface and high dimensional accuracy.

Which is suitable for the production of large batches of precision parts.

Disadvantages: high cost, complex process, not suitable for mass production.

Pressure casting

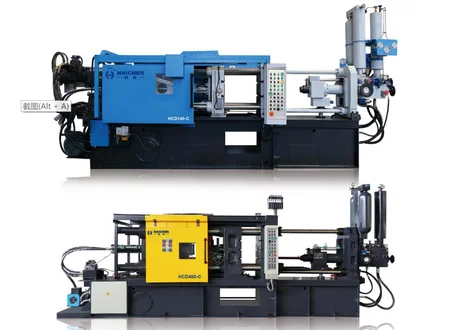

Haichen specializes in high-pressure die casting, including hot chamber die casting machines and cold chamber die casting machines.

Advantages: It is suitable for the production of thin-walled and complex-shaped castings.

With high casting density and good mechanical properties, and is suitable for mass production.

Disadvantages: high cost, high requirements for molds, not suitable for simple shapes or large castings.

Other methods

Shell casting: suitable for mass production, high dimensional accuracy of castings, low surface roughness, but high cost.

Centrifugal casting: suitable for the production of large castings, but the cost is high and the size and shape of the casting are limited.