Hot Chamber Die Casting Fundamental is an efficient and high-precision metal casting process that is mainly used for the forming of low-melting alloys such as zinc, tin, lead, and magnesium-based alloys.

Hot chamber die casting, a highly efficient and precise manufacturing process, is widely applied across various industries.

Furthermore, with a history spanning centuries, this method has continuously evolved to reliably produce intricate metal components for diverse applications, ranging from industrial machinery to household appliances.

In Haichen, we possess extensive hot chamber die-casting technology and can design various molds.

We ensure that the metal die-casting process achieves the best quality and speed, thereby meeting the highest performance standards and customer satisfaction.

Hot Chamber Die Casting Historical Milestones

- 1849

- 1915

- 1992

- 21st century

1849

J.J. Sturgiss builds the first manual piston hot chamber die casting machine for lead casting.

Laying the foundation for the process.

1915

The first commercial production of aluminum alloy die castings in the United States.

But due to the problem of material corrosion, the hot chamber machine mainly turned to zinc alloy.

1992

Toyo Machinery of Japan developed a hot chamber die-casting machine for vertical aluminum.

Breaking through the bottleneck of high melting point alloy application.

21st century

Popularization of automation and computer control technology to optimize cycle times (3000–7000 cycles/8 hours for small machines).

What is Hot Chamber Die Casting?

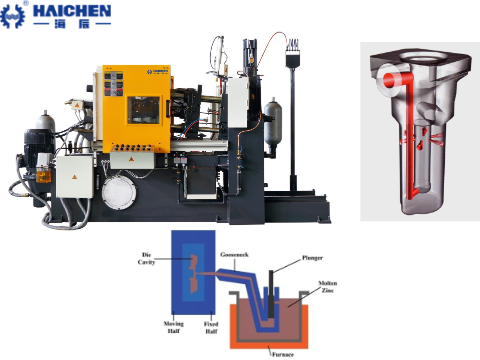

Hot chamber die casting is a manufacturing process where manufacturers create metal parts by injecting molten metal into a mold cavity at high temperatures.

Specifically, the term “hot chamber” describes machinery that stores molten metal directly within a container connected to the die casting machine .

In contrast, cold chamber die casting requires operators to ladle molten metal from an external furnace into the machine before injecting it into the die cavity, typically at higher pressures than the hot chamber process.

The Hot Chamber Die Casting Process

- Preparation

- Melting

- Injection

- Solidification

- Ejection

Preparation

The process commences with the preparation of the die, usually made from hardened steel, which is then securely mounted onto the die casting machine.

Melting

In the hot chamber, a crucible containing the metal, typically zinc, magnesium, or lead-based alloys with low melting points, is heated to a liquid state.

Injection

Once molten, a piston forces the metal into the die cavity under high pressure.

The pressure helps ensure that the liquid metal fully fills the mold, resulting in detailed and accurate parts.

Solidification

After the mold is filled, the molten metal rapidly cools and solidifies within the die cavity, taking the shape of the mold.

Ejection

Finally, the newly formed part is ejected from the mold, and excess material, known as flash, is trimmed off.

The advantages of Haichen hot chamber die casting

The die-casting process has numerous advantages, making it the preferred solution for manufacturing complex metal components:

- High precision

- Fast production

- Complex shapes

- Material diversity

High precision

Haichen’s hot-chamber die-casting technology can produce parts with high dimensional accuracy, excellent surface finish.

And narrow tolerance range, thereby reducing the need for subsequent processing procedures.

Fast production

Secondly, Haichen’s die-casting machines have high-speed production capabilities, making them highly suitable for mass-producing components in a short period of time.

Complex shapes

This process can easily achieve the production of complex shapes and maintain consistency across multiple components.

Material diversity

It can be compatible with various metals and alloys, allowing for flexible selection of materials based on specific application requirements.

Hot Chamber Die Casting Key Features

- Hot Chamber Integration

- Gooseneck Injection System

- Low melting point material adaptability

Hot Chamber Integration

The molten metal is always stored in the furnace connected to the die casting machine.

Without the need for external transfer, reducing heat loss and oxidation risk.

Gooseneck Injection System

A piston is used to drive liquid metal through a gooseneck tube into the mold, ensuring a fast, continuous flow of metal.

Low melting point material adaptability

Only suitable for alloys with melting point lower than 420°C to avoid corrosion of equipment components at high temperatures.

Hot Chamber Die Casting Fundamental

- Metal melting

- Injection stage

- Cooling & Demolding

Metal melting

The furnace is built into the die casting machine, and the metal remains liquid at a temperature below about 400°C generally.

Injection stage

In general,the piston sucks the molten metal into the chamber through the gooseneck and injects it into the mold at high pressure (7-35 MPa).

Cooling & Demolding

First, a cooling system inside the mold quickly solidifies the material.

Then, the ejector pin pushes out the molded part.

Moreover, with a cycle time of only about 20 minutes, this process is highly efficient for high-volume production.

Applicable material type

- Zinc alloy

- Magnesium alloy

- Applications

- Limitations

Zinc alloy

Melting point of only 380-390°C , excellent flowability, suitable for delicate small parts (e.g. electronic connectors) correspondingly.

Magnesium alloy

Density 1.8 g/cm³, high specific strength, excellent electromagnetic shielding performance eventually.

Applications

laptop shells, drone frames. Lead/tin alloy Uses: nuclear radiation shielding parts, battery plates (gradually replaced).

Limitations

Copper alloys (e.g., brass) are occasionally used, but furnace temperatures need to be controlled to prevent equipment corrosion.

Future Innovations and Sustainability

Furthermore, continual technological advancements drive innovations in die casting, while researchers and manufacturers actively improve energy efficiency, reduce production waste, and explore sustainable materials.

- Environmental Considerations

- Additive Manufacturing Integration

- Process Optimization

Environmental Considerations

Furthermore,there’s a growing emphasis on using recycled materials and developing eco-friendly alloys to minimize the environmental impact of the die casting process.

Additive Manufacturing Integration

Moreover, researchers are exploring how to integrate additive manufacturing techniques with die casting to enhance design flexibility and produce more intricate structures.

Process Optimization

Ongoing research focuses on optimizing the process parameters to reduce energy consumption and material waste while maintaining quality.