The landscape of Die Casting Technology is undergoing a transformative shift, rapidly advancing towards unprecedented levels of efficiency, precision, and sustainability. This evolution is largely driven by the sophisticated integration of advanced materials, intelligent process controls, and cutting-edge data analytics.

Die casting is a high-precision primary forming process that uses high pressure to shape lightweight metal materials within a steel mold. This process has extremely wide applications, found in almost all capital goods and consumer products.

The automotive industry accounts for over 70% of the global die casting market, making it a major customer. Furthermore, many aerospace electronic products, as well as important components for everyday consumer goods and home improvement equipment, are also produced using this Die Casting Technology.

Below is a detailed analysis across multiple dimensions:

Research and development direction of precision die casting

- Material Innovation and Lightweighting

- Large-Scale Integrated Die Casting

- Intelligent and Digital Transformation

- Green Manufacturing and Sustainability

- Industry Applications and Expansion

Material Innovation and Lightweighting

- Advanced Alloys and Composites: Traditional aluminum and zinc alloys are expanding into magnesium alloys and hybrid composites. Magnesium alloys offer superior strength-to-weight ratios, ideal for lightweighting in aerospace and NEVs. For example, Tesla’s use of integrated die casting consolidates 70+ car body parts into a single aluminum casting, reducing weight while enhancing structural rigidity.

- Performance Enhancement: Improved alloy formulations and heat treatment techniques (e.g., cold-chamber die casting to minimize oxide inclusions) enhance mechanical properties and corrosion resistance. Cold-chamber machines enable high-melting-point aluminum alloys for complex thin-walled components.

Large-Scale Integrated Die Casting

- Mega Die Casting Machines:9000T die casting machine produces integrated car frames and rear chassis components, shifting automotive manufacturing from “multi-part assembly” to “fewer integrated parts.” This reduces assembly steps and costs, with applications in automakers like FAW. Future expansion may include battery housings.

- Challenges: While integrated casting reduces weight by over 30%, high mold costs (up to millions per set) and post-collision repair challenges persist. Modular mold design and quick mold-change technologies are being adopted to address these issues.

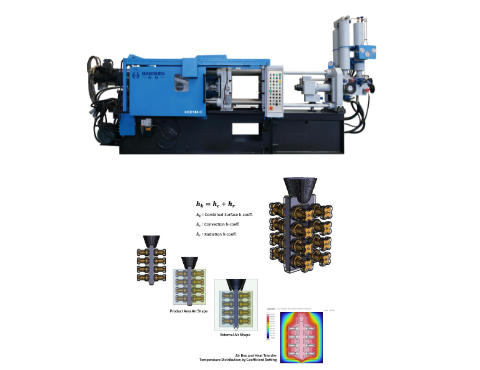

Intelligent and Digital Transformation

- AI and Machine Vision: AI-powered real-time defect detection (e.g., porosity analysis) combines high-resolution imaging and high-speed processing to improve quality control. Machine vision systems monitor melt flow dynamics to optimize filling.

- Simulation and Industry 4.0: CAE (Computer-Aided Engineering) simulations predict deformation and stress distribution, reducing trial-and-error cycles. Industrial IoT enables remote monitoring and smart scheduling for higher automation.

Green Manufacturing and Sustainability

- Circular Economy: Recyclable alloys (e.g., recycled aluminum) and closed-loop material systems minimize waste. Haichen collaborates with partners to develop low-carbon solutions.

- Energy Efficiency: Thermal management innovations (e.g., vacuum technology to reduce melt oxidation) and energy recovery systems lower energy consumption. The LEAP series uses smart controls to boost efficiency.

Industry Applications and Expansion

- NEV-Driven Growth: Die Casting Technology extends from vehicle bodies to electric drive systems and battery components. Changan Auto is exploring integrated casting for battery trays to improve safety and cost-effectiveness.

- Cross-Sector Potential: High-precision medical devices (e.g., imaging equipment housings) and complex 5G base station heat sinks increasingly adopt die casting, driving industry diversification.

Challenges and Future Directions

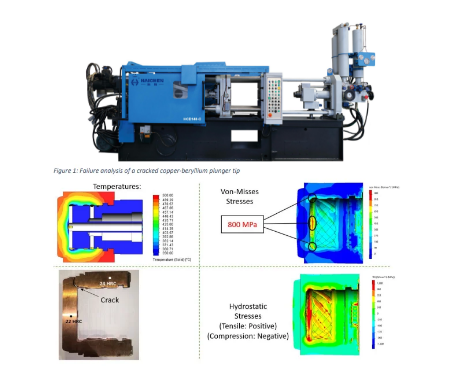

- Technical Bottlenecks: Mold longevity and thermal fatigue in large castings require breakthroughs in coatings and tool steels (e.g., wear-resistant hard alloys).

- Cost and Standardization: High upfront investments (e.g., mega die casting machines) demand industry collaboration and policy support. A lack of standardized design guidelines hinders large-scale adoption.

Future die casting machine design

The evolution of die casting machines will focus on integrating advanced technologies and addressing industrial demands, with key directions including:

- Large-Scale Machines & High Clamping Force

- Smart Manufacturing & Automation

- Sustainability & Environmental Innovation

- Ultra-Precision & Reliability

- Modular & Flexible Architecture

- Material-Mold Synergy

- Global Competition & Tech Breakthroughs

Large-Scale Machines & High Clamping Force

To meet automotive “megacasting” needs (e.g., Tesla’s 6,000-ton GIGAPRESS for Model Y rear underbody), die casting machines are scaling up to 9,000–12,000 tons. Challenges include:

- Structural optimization for ultra-high clamping forces to prevent mold deformation.

- Hydraulic system upgrades to balance power efficiency and stability.

- Cost reduction through simulation-driven design and modular components.

Smart Manufacturing & Automation

AI, IoT, and robotics will redefine production workflows:

- Real-time monitoring: Sensors track parameters (pressure, temperature) to auto-adjust processes.

- Predictive maintenance: Machine learning identifies wear patterns, cutting downtime by 20–30%.

- Robotic integration: Autonomous systems handle mold changes, part removal, and recycling (e.g., IDRA’s DCM software).

Sustainability & Environmental Innovation

Green technologies will dominate:

- Closed-loop systems: Regenerative injection (e.g., GIGAPRESS 5S© tech) reduces energy waste.

- Material efficiency: Recyclable alloys (e.g., heat-treatment-free aluminum) lower CO₂ emissions.

- Emission control: Advanced filtration captures particulates and volatile organic compounds (VOCs).

Ultra-Precision & Reliability

Demand for defect-free parts drives innovation:

- CNC-controlled injection: Nanoscale accuracy in filling speed/pressure minimizes porosity.

- Thermal management: Adaptive mold cooling ensures dimensional stability for complex geometries.

- Durability: High-performance alloys (e.g., tungsten carbide coatings) extend component lifespan.

Modular & Flexible Architecture

Adaptability for diverse industries (EVs, 3C, aerospace):

- Plug-and-play modules: Quick reconfiguration for multi-material casting (e.g., Mg-Al hybrid parts).

- Rapid mold swapping: Automated systems reduce changeover time to <10 minutes.

- Scalability: Compact designs for SMEs vs. gigacasting systems for OEMs.

Material-Mold Synergy

Advancements in alloys and tooling:

- High-strength lightweight alloys: Compatibility with Al-Si-Cu/Mg-RE alloys for thin-wall castings.

- Smart molds: Embedded sensors monitor stress and thermal gradients in real time.

- Topology-optimized dies: AI-driven designs reduce weight by 15% while maintaining rigidity.

Global Competition & Tech Breakthroughs

China’s rise (e.g., LK Group, Haichen) challenges EU/US dominance:

- Core tech gaps: Precision hydraulics and control software still rely on imports (e.g., Bühler, Frech).

- R&D priorities: High-speed shot control (<50 ms fill time) and multi-stage injection for hybrid components.

Outlook

Future die casting machines will merge scale, intelligence, and eco-efficiency to enable:

- EV lightweighting: Single-piece castings reduce vehicle weight by 10–15%.

- Zero-defect production: AI-powered quality assurance for critical components (e.g., battery housings).

- Circular ecosystems: Closed-loop material reuse and carbon-neutral operations.

Companies that prioritize R&D in automation, material science, and energy efficiency will lead the next industrial revolution in die casting.

The future of Haichen die casting machines

Future Development of Haichen Die-Casting Machines

The future development of Haichen die-casting machines will focus on technological innovation, market expansion, and adaptation to industry trends, as outlined below:

- Technological Innovation and Intelligent Upgrades

- Market Expansion and Industry Diversification

- Industry Trends: Integrated Die-Casting and Globalization

- Challenges and Strategies

Technological Innovation and Intelligent Upgrades

- Smart Manufacturing: Haichen Die Casting Technology has integrated servo-controlled hydraulic injection, vacuum die-casting, and squeeze casting technologies. Plans include advancing intelligent control systems (e.g., full PLC automation and real-time injection curve monitoring) to enhance precision and efficiency.

- Large-Tonnage Machines: While current models max out at 3,000 tons (30,000 kN), rising demand for 6,000+ ton ultra-large machines (e.g., for automotive integrated die-casting) requires accelerated R&D to stay competitive.

- Energy Efficiency & Sustainability: Servo-driven energy-saving systems, low-noise hydraulics, and alloy recycling technologies will reduce energy consumption and align with global sustainability goals.

Market Expansion and Industry Diversification

- Automotive Sector Focus: Emerging markets like Mexico and India show strong demand for integrated die-casting solutions. Haichen can leverage customized offerings (e.g., high-precision aluminum alloy machines) to strengthen its foothold. Emphasis on NEV (New Energy Vehicle) components (e.g., lightweight chassis, battery housings) is critical.

- Multi-Industry Applications: Beyond automotive, Haichen machines are used in home appliances, 3C electronics, and hardware tools. Future expansion into aerospace and construction will capitalize on adaptable designs for diverse needs.

Industry Trends: Integrated Die-Casting and Globalization

- Integrated Die-Casting: Align with the trend toward large-scale, integrated production (e.g., Tesla-style single-piece body casting). Collaborate with clients to develop molds, automation, and end-to-end solutions.

- Global Strategy: Leverage multilingual interfaces (English, Spanish) and CE certification to penetrate Europe and Latin America. Boost brand visibility through international exhibitions (e.g., Shanghai Die-Casting Expo).

Challenges and Strategies

- Competition: Global leaders like Bühler (Switzerland) and Haichen have launched ultra-large machines. Haichen must increase R&D investment to bridge technological gaps.

- Supply Chain Collaboration: Partner with machine tool manufacturers (following Haitian Group’s model) to offer integrated die-casting-machining solutions, improving customer retention.

Haichen’s future Die Casting Technology lies in smart, large-scale, and eco-friendly die-casting solutions. By prioritizing innovation, global expansion, and alignment with integrated die-casting trends, it aims to solidify its position in automotive and emerging industries while capturing growth in new markets.

By the end

This powerful evolution, particularly its widespread adoption within the burgeoning New Energy Vehicle (NEV) sector and other diverse industrial manufacturing applications, is poised to fundamentally redefine modern production paradigms. Expect significant impacts across industries relying on high-quality, lightweight components.

Looking ahead, key drivers for continued innovation in die casting and future breakthroughs are anticipated in areas such as the development of ultra-large-scale equipment for complex parts, AI-powered optimization of the entire casting process from design to production, and the seamless integration of circular economy principles for enhanced sustainability and resource efficiency. These advancements promise a more robust, environmentally friendly, and cost-effective future for metal component manufacturing.