The Role of Robots in Die Casting: Robots handle parts, increase accuracy, and maintain safety in harsh and hot production environments.

With die casting, sharp and detailed metal parts can be produced in an accurate and consistent manner.

In contemporary die casting, robots are employed. They have the ability to boost efficiency, quality, and safety. This article will look into the different responsibilities of robots in die casting.

We will observe how they assist in the general success of the entire manufacturing process.

Improvement of Production Efficiency

Robots are the single most important reason for the continuous improvement of productivity in die-casting processes. Robots perform repetitive actions like spraying molds with the utmost accuracy and speed, which leads to a decrease in cycle time.

They are also able to perform removal of parts from the mold and trim the extra materials. Automation ensures every cycle is executed faultlessly. Due to the staggering amount of tasks that need to be performed, the financial costs go down, and production rates rise. This precision and efficiency are helpful in cases where volumes of goods are produced.

Enhancement of Casting Quality

Casting quality is heavily influenced by robotic technology. For accuracy and consistency, robots must be able to apply processes uniformly, for instance, the spraying of mask and trim.

With robots, release agents can be applied to the whole surface of the mold for casting, leading to improved quality. This prevents various defects like sticking or uneven surface finish. Sufficiently delicate parts can be gripped without the risk of damage during handling.

This leads to better quality castings due to fewer defects. Consequently, manufacturers are able to control quality in a better way. They are also able to meet strict requirements of the industry more efficiently.

Improving Safety At Work

In the die casting industry, the safety of the workers is always a priority. A great deal of risk can be alleviated with the use of robots which can undertake tedious and perilous tasks such as maintaining molten metal or controlling super-hot molds.

Since robots can work without breaks, the constant need for human attention is eliminated, and human error is reduced.

Customization and Programming Adaptable, Efficient And Specific To Die Casting

Robots are extremely versatile and flexible. They are able to accommodate to varying die casting operations such as differing part configurations and sizes for molds and production needs.

This ultimately allows for rapid response to fluctuations in the scope of work. The ever-changing world of manufacturing makes adaptability a necessity.

Integration of Advanced Technologies

In die casting operations, modern robots are alwasy coupled with the latest tools such as data analytics, sensors, and vision systems. These augment the efficiency with which robotic arms preform casting.

These technologies enable robots to perform tasks with even greater precision and accuracy. For instance, vision systems can guide robots to precisely place parts.

They can also detect defects in real-time. Relevant data can be collected with regards to the condition of the mold and the casting process. They help in optimizing the processes.

With the use of these modern technologies, manufacturers can attain higher levels of automation and control over processes. This guarantees enhanced efficiency and quality.

Lowering Labor Expenditures

Incorporating robots in die-casting can significantly reduce labor costs. Although the robots may be expensive now, the savings in the long run, especially in labor cost-s associated with constant work without breaks or overtime, can be clubbed together for a major saving.

The reliance reduction on manual work not only alleviates the shortage in workforce but promotes healthy balance in the workforce. This competitive advantage can have increased savings for manufacturers facing competition on a global scale.

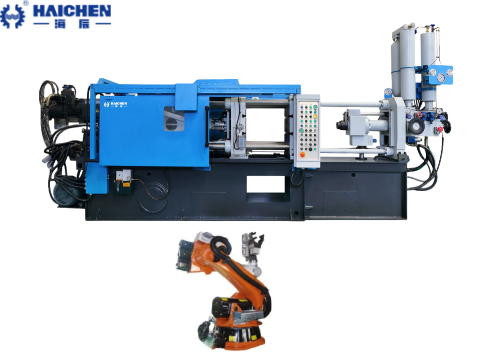

HAICHEN Robot Solutions: Technical Specifications and Applications

As a supplier of die casting equipment and automation solutions, HAICHEN provides a dedicated series of robots that integrate deeply with die casting machines. They aim to achieve full automation from part extraction to post-processing, enhancing overall production line efficiency.

- HAICHEN Robot Product Line and Core Technical Features

- Key Performance Specifications

- Application Case: Integrated Cell Boosts Production Efficiency

HAICHEN Robot Product Line and Core Technical Features

HAICHEN’s robot product line covers the main requirements for post-casting operations. Its Horizontal Type Manipulator and Single-Axis Servo Manipulator are core products. The Horizontal Type uses a rigid bridge structure for stable operation, suitable for large-range, heavy-load part extraction and transfer tasks. The Single-Axis Servo Manipulator features high speed and high repeatability positioning precision, driven by a servo motor. It is particularly suited for precise spraying, insertion, or fast extraction of lightweight parts. These devices are designed for seamless communication with HAICHEN die casting machine control systems, enabling precise synchronization of the production cycle.

Key Performance Specifications

According to HAICHEN product documentation, its robots are designed to meet the high demands of die casting production:

- Stroke and Load: For example, its Single-Axis Servo Manipulator offers various stroke specifications (e.g., Horizontal Stroke: 485mm/750mm, Vertical Stroke: 510mm), with a maximum load (including gripper) of up to 3kg, meeting the handling needs of most small to medium-sized castings.

- Speed and Cycle Time: The dry cycle time (without load) can be as short as 9 seconds. Combined with fast pneumatic or servo drives, it significantly reduces non-productive time, directly improving the effective utilization rate of the die casting machine.

- Structural Rigidity: Constructed from materials like high-strength aluminum alloy, ensuring long-term stable operation in the harsh environment of a die casting shop (high temperature, dusty) with low maintenance requirements.

Key Specifications Table (Example: Single-Axis Servo Manipulator)

| Parameter / Specification | Unit | Model A (Standard) | Model B (Long Stroke) |

|---|---|---|---|

| Horizontal Stroke | mm | 485 | 750 |

| Vertical Stroke | mm | 510 | 510 |

| Rotation Stroke | ° | 180 | 180 |

| Drive Type | – | Servo Motor | Servo Motor |

| Max. Load (with gripper) | kg | 3 | 3 |

| Dry Cycle Time (without load) | sec | ≤ 9 | ≤ 9 |

| Working Air Pressure | MPa | 0.5 – 0.7 | 0.5 – 0.7 |

| Power Supply | – | 220V / 50Hz | 220V / 50Hz |

| Net Weight | kg | ~250 | ~250 |

Application Case: Integrated Cell Boosts Production Efficiency

An automotive parts manufacturer in Thailand integrated a HAICHEN die casting machine with a matching Single-Axis Servo extraction robot. The robot is tasked with extracting large aluminum steering knuckle castings from a 650-ton die casting machine. Following a pre-set, precise trajectory, the robot reliably avoids ejector pins and complex mold features, grasps the casting, and places it onto a conveyor belt. Compared to traditional manual extraction, this automated cell reduced the production cycle time by approximately 15%. It completely eliminated safety hazards for workers and product damage caused by the hot environment or operational fatigue, ensuring stable production efficiency and delivery quality for this workstation.

HAICHEN’s Commitment to Innovation

As one of the die casting machine manufacturers for robotic technologies, HAICHEN is integrating world technologies to enhance efficiency, safety, and production of quality single and multi-station die casting machines.

With robotic technology added to die-casting, our innovations enhance the reliability and efficiency for die-casting customers. HAICHEN remains devoted to help manufacturers improve their productivity, control the quality optimally, and most importantly have a safe workspace.

We are also exploring other methods to reduce costs and increase eco-friendliness.

In summary, robots have a significant impact on operations related to die casting.They help improve productivity, maintain casting quality, ensure workplace safety, provide flexibility and customization, integrate with new technologies, and simplify the workforce.