Thermocouple Life Extension Solutions in die casting includes optimize design and install, select material and protect measures, and so on.

By optimizing the design and installation of thermocouples, selecting appropriate materials and protection measures. Moreover, properly managing temperature ranges and thermal cycles, improving cooling systems.

Reducing the impact of mechanical stress, and performing regular maintenance. Thus the service life of thermocouples in the die casting process can extend significantly. Thereby improving the overall life of the mold and production efficiency.

In the die casting process, extending the life of the thermocouple is an important means to improve the mold life and production efficiency.

Optimize design and installation of thermocouples

The design and installation of thermocouples directly affect their life. For example, by improving the support structure of the thermocouple, such as using a shorter support rod (3.2 mm diameter mild steel) to reduce fluid interference and fixing the thermocouple in the center of the mold cavity. It can improve its stability and reduce wear.

In addition, the use of embedded thermocouple design, such as forming micro grooves on the mold surface to fix the thermocouple. That can protect the thermocouple from cutting and wear, while achieving fast response.

Select high-temperature and wear-resistant materials

- Sheath: Inconel 600, Inconel 625, Stainless Steel 316/310, or high-temperature ceramics (alumina, silicon nitride Si₃N₄) significantly improve corrosion and wear resistance.

- Protective tube: Silicon nitride or silicon carbide composite tubes are virtually non-wetting in molten non-ferrous metals such as aluminum and zinc, and have a service life of 3-6 months or longer.

- Thermocouple body: Mineral insulated (MI) or ceramic insulation maintains stability in high-temperature and high-vibration environments.

Appropriate contact and grounding methods

- Contact type: In high-temperature and high-electromagnetic field environments, ungrounded contacts are recommended, along with shielded sheaths and grounded shielding to minimize inductive errors.

- Connector material: Use high-temperature-resistant alloys or ceramic connectors to prevent loosening or failure due to differential thermal expansion. Protective Head and Seals

- The IP65/IP67-rated die-cast aluminum or stainless steel housing, with O-ring seals and a dust- and water-resistant threaded cap, protects against the intrusion of coolant and dust.

Protective Head and Seals

IP65/IP67-rated die-cast aluminum or stainless steel housing with O-ring seals and dust- and water-resistant threaded caps prevents the intrusion of coolant and dust.

Material selection and protection measures

Using high-quality thermocouple materials (such as K-type thermocouples). And using appropriate protective sleeves (such as alumina protection tubes or PTFE sealing sleeves). These can significantly extend the life of the thermocouple.

Use a closed metal protection tube

A closed-end metal tube (Inconel, CrNi-steel) with an inner, airtight ceramic tube significantly reduces oxidation and chemical attack.

Create a thermal well

Preserve a metal or ceramic well on the mold surface and place the thermocouple inside to avoid direct contact with the molten metal.

Radiation shielding

Add a highly reflective metal or ceramic shield to the hot end of the thermocouple to reduce the rate of thermal shock.

Avoid thermal cycling

If the process allows, use a preheat-soak-slow-cool profile to reduce temperature gradients; or use mineral-insulated thermocouples, which are more resistant to thermal shock.

Temperature Range and Thermal Cycle Management

The life of a thermocouple affectes by the operating temperature range and thermal cycles. Studies have shown that the life of a thermocouple is significantly reduced when the temperature is increased or when thermal cycles are frequent.

Therefore, it should minimize the number of thermal cycles in the design. And it should select a thermocouple type that can work stably under high temperature conditions (such as S-type or R-type thermocouples).

Typical temperature ranges for thermocouples in die casting

- Melt temperature: 650-720°C for aluminum alloys, 900-1150°C for zinc alloys.

- Mold surface temperature: 150-300°C (typically 200-250°C) at steady state.

Choose high-temperature, thicker compensation wire

- For example, 24AWG fiberglass-insulated Type E wire has an operating temperature of up to 400°C.

- Using 19-strand or thicker conductor construction improves mechanical strength and thermal resistance.

Using specialized protective tubing

- Ceramic or metal sheaths resist thermal shock and chemical corrosion, significantly increasing service life.

- Extension cables with ETFE cross-linked insulation and metal sheaths have an operating temperature range of –65°C to +200°C and are suitable for mold surface monitoring.

Optimize the thermal cycle

- Preheating: Preheat the mold to the target temperature before injection to avoid sudden temperature rise.

- Controlled cooling: Use embedded cooling channels or localized cooling blocks to maintain a temperature drop rate within 5-15°C/s to reduce thermal shock.

- Temperature gradient control: Real-time monitoring via a PLC allows for upper and lower limit alarms to prevent overheating or undercooling.

Cooling system and mold temperature management

Lowering the mold surface temperature is one of the key measures to extend the mold life. By optimizing the cooling system, such as increasing the number of cooling channels or improving the coolant flow path. It can effectively reduce the mold temperature, thereby reducing the impact of thermal stress on the thermocouple.

In addition, the reasonable distribution of the temperature of different areas of the mold (such as the top cover and the ejection side) helps to extend the overall life of the mold and the thermocouple.

Mechanical stress and vibration management

Thermocouples may be subject to mechanical stress or vibration during use, which will accelerate their aging.

Therefore, it should minimize the design in the design, such as by improving the design of the thermocouple bracket or using a flexible protective sleeve to absorb vibration.

Regular maintenance and calibration

Regular inspection and calibration of thermocouples is an important step to ensure their long-term reliable operation.

By comparing the performance differences between old and new thermocouples and replacing aging probes in time, it can avoid the measurement problems caused by error accumulation.

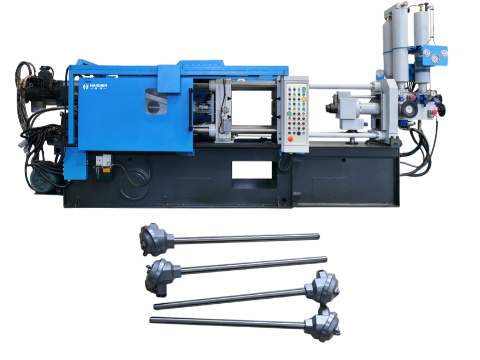

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. At the same time, we produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.