There are three platen types of Die casting machine:

- Fix platen: the first platen

- Movable platen: Open and close the mold

- Third platen: platen to adjust the mold thickness

A die casting machine platen is a large, thick, flat steel plate that holds the two halves of a die in place during the die casting process. We focus on the movable platen and the fixed platen.

Total 3 platen types of Die casting machine on the clamping unit.

The movable platen for die casting machine

It fixes on the die-casting machine’s die-opening mechanism and can move horizontally with the drive of the die-opening mechanism, thereby realizing the closing and opening of the mold. The movable platen is usually equipped with a cavity and a core, which are used to form the outer contour of the casting.

Definition and location

The movable platen is a thick steel plate that can be moved in the die casting machine. It is usually located at the rear of the machine and connected to the ejector die. It works with the stationary platen and slides through tie bars to open and close the die.

Drive mode

The movement of the movable platen is driven by a hydraulic system or a servo motor:

Hydraulic drive

Driven by a hydraulic cylinder (such as a traverse cylinder), which is common in traditional die casting machines.

Core function

- Mold opening and closing:The reciprocating motion of the movable platen realizes the closing (molten metal injection) and opening (casting ejection) of the mold.

- Clamping force maintenance: During the injection stage, the movable platen and the fixed platen are tightly closed, bearing the high-pressure clamping force to prevent the mold from being opened by the pressure of the molten metal.

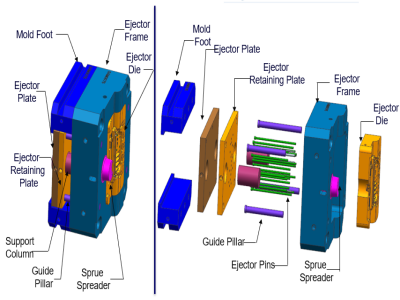

- Ejector mechanism carrier: The movable platen is usually integrated with the ejector pins/plate, which is used to eject the casting from the mold after the mold is opened.

Maintenance and safety requirements

Cleanliness and parallelism: The mounting surface of the movable template must be kept clean and parallel to the fixed template to avoid mold deflection affecting casting quality and heat conduction.

Safety protection: There is a risk of extrusion in the toggle mechanism area, and protective devices must be equipped and the energy source must be locked during maintenance (Zero Energy State).

Wear management: The movable template slides on the wear-resistant plate through “shoes”, and wear parts must be replaced regularly to ensure movement accuracy.

The movable platen is the core moving part of the die-casting machine, and its design directly affects production efficiency, casting accuracy and equipment reliability.

The fixed platen for die casting machine

This platen fixes on the fixed die plate of the die casting machine and is the part where the molten metal enters the die casting mold cavity. It provides with a cavity to form the outer contour of the casting and complete the overall shape of the casting together with the cavity on the movable platen.

Definition of fixed platen

The fixed platen is a large rectangular steel plate, usually mounted on the die endpiece of the die casting machine frame, used to fix the cover die/fixed die half of the die.

Main function

Mold fixation: The cover die is firmly mounted on its surface by bolts or T-slots to ensure that the mold remains stable during high-pressure injection.

Maintain closing pressure: Cooperate with the movable platen, withstand high pressure (usually thousands of pounds per square inch) under the action of the hydraulic clamping mechanism to prevent the mold from opening when the molten metal is injected.

Precision alignment: Ensure the dimensional accuracy of the mold cavity and the quality of the casting by aligning it parallel to the movable platen.

Injection channel: The fixed platen is usually designed with a shot hole for connecting the injection sleeve or pressure chamber to allow the molten metal to be injected into the mold.

Position and structural design

Position

Located at the die end of the die casting machine frame, opposite to the movable platen. The movable platen is guided by tie bars and slides along the tie bars to open and close the die.

Structural features

- Material and strength: Made of high-rigidity medium carbon steel or alloy steel to withstand clamping force and injection pressure.

- Mounting interface: The surface is machined with T-slots or threaded holes for fixing the die and shot block adapter

- Special design: Some fixed platens are equipped with removable parts to facilitate the installation of die units with side core pulling cylinders. Some models are also equipped with calibration targets for optical alignment of the shot unit and the platen channel

Role in the die casting process

Mold closing stage: The hydraulic clamping mechanism pushes the movable die plate toward the fixed die plate, closes the mold and applies clamping force.

Injection stage: The molten metal is injected into the mold cavity through the injection sleeve of the fixed die plate, and the die plate needs to resist the injection reaction force.

Mold opening stage: After the casting solidifies, the clamping mechanism is released, the movable die plate retreats, and the casting usually remains on the ejector side of the movable die plate (ejector die), and the fixed die plate remains stationary.

Maintenance requirements: The die plate surface needs to be cleaned regularly to ensure that the die mounting surface is flat to maintain heat transfer efficiency and die parallelism.

The fixed platen is a key component for load bearing, positioning and metal injection in the die casting machine. Its design directly affects the die life, casting accuracy and equipment stability.

The third platen of die-casting machine

The third platen is the last type platen types of Die casting machine.

Function of core components

The clamping unit of a die-casting machine usually contains three main templates (three-plate design):

- Fixed template (Cover platen): Install the fixed mold and connect to the injection system.

- Moving template (Ejector platen): Install the movable mold and connect the ejection mechanism.

- The third template (Rear platen): Located at the rear end of the machine, it serves as the support point of the toggle clamping mechanism or the tie rod and bears the clamping force.

Main functions

- Adjusting the mold template by adjusting the thickness and position of the mold

- Ensure stable clamping force of the mold,To avoid production problems caused by improper installation or inaccurate adjustment of molds.

- In addition, adjusting the mold template can also shorten the installation time of the mold, improve production efficiency. And optimize the design to make the stress distribution of the template uniform. Thereby improving the durability and service life of the mold.

Technical advantages of the third template

Stability and precision: The three-template structure ensures mold parallelism and reduces deformation through a mechanical toggle clamping mechanism, which is especially suitable for high-precision parts. The thickened three-template design improves strength and wear resistance, and the middle plate reinforcement rib structure further suppresses deformation.

Production efficiency optimization: Electric servo drive achieves high-speed positioning and programmable control of the third template, shortening the cycle time.

Maintenance and energy efficiency: The mechanical toggle structure has been verified for decades, with a low failure rate and lower maintenance costs than hydraulic systems.

Eliminating the hydraulic oil tank (such as the E series) reduces floor space and energy consumption.

The third template is the core load-bearing component of the traditional three-template die-casting machine. It ensures stability and precision through a mechanical toggle mechanism and is particularly suitable for high-precision, large-scale production.

Optimize design

- Topology optimization: In order to reduce the weight of the die casting machine platen and improve its performance, topology optimization techniques are often used in the design of modern die-casting machine platens. Through software simulation and calculation, optimize the material distribution of the template, reduce unnecessary material usage, while maintaining or enhancing the strength and stiffness of the structure.

- Material selection: The selection of die casting machine platen materials is also crucial, and commonly used materials include ductile iron, which has good mechanical and processing properties.

- Precision machining: The manufacturing of die casting machine platen usually requires high-precision mechanical machining to ensure the smoothness and dimensional accuracy of the template surface, which is crucial for ensuring the quality of die-casting parts.

Summary

A die casting machine platen type mainly includes stationery platen and movable platen, which work together through precise mechanical structures and hydraulic systems to achieve efficient casting processes. The design of these templates not only needs to consider the fluidity and cooling characteristics of the materials, but also the stability and durability of the molds to ensure product quality and production efficiency.The future trend will be the coexistence of the two: the three-template continues to dominate small and medium-sized precision parts, and the double-template gradually penetrates the large-tonnage market.