While diecast tooling suffers from wear and fatigue, erosion or washout is the main failure mode of tooling in aluminum diecasting. Aluminum has relatively high chemical reactivity and solubility in iron.

While in contact with iron, molten aluminum atoms diffuse into the iron matrix and form intermetallic compounds, such as Fe2Al5. These intermetallic phases melt at above 1000°C.

This is in contrast to molten aluminum, which is 700°C at most when poured onto steel tooling.

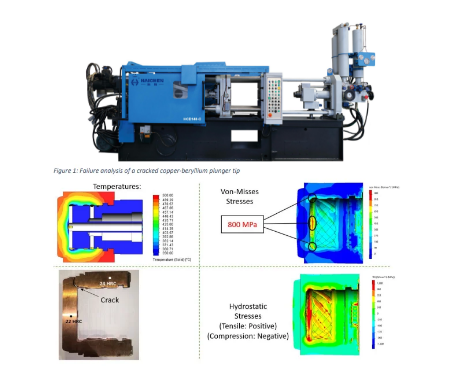

The main mechanism causing shot sleeve washout is when the plunger tip gets in contact with the sleeve surface, and the brittle phases formed at the surface break apart.

Once the intermetallic particles are removed from the tool surface and go into the melt.

They may not get enough time to dissolve into molten aluminum before solidification.

The result is that they end up in the part and degrade mechanical properties.

Failure Analysis in Die casting

- Fracture failure

- Corrosion failure

- Thermal fatigue crack damage failure

Fracture failure

Under the action of injection pressure, the mold will initiate cracks in the most fragile place.

Especially the surface where the traces of the molding line or the traces of electrical machining are not completed, or the place where a clear angle is formed will be the first small crack.

The presence of brittle phases or coarse grain boundaries is easy to fracture.

The rapid growth of cracks, brittle fracture, and mold fracture are the risk factors for failure.

Therefore, on the one hand, scratches on the surface of the mold, electrical machining marks must be polished, even if it is in the pouring system, it must be illuminated.

It also requires high strength, good plasticity using advanced materials, and good impact toughness and fracture toughness.

Corrosion failure

Commonly used molds and zinc alloys, casting alloys, aluminum alloys, magnesium alloys and copper alloys.

There are also pure aluminum alloy die-casting, zinc metal elements, aluminum and magnesium are a kind of lively, they have a good affinity, mold materials, especially aluminum sheet.

When the mold hardness is high, it has good corrosion resistance.

If there are soft spots on the molding surface, it is anti-corrosion.

Thermal fatigue crack damage failure

In the process of die casting mold production, the quenching effect of the hot forming surface and its internal deformation occur repeatedly.

And the repeated thermal stress interacts, resulting in structural damage and elastic loss, leading to the appearance of micro-cracks.

And causing the surface structure and internal structure of the casting to occur fracture.

When the crack propagates, stagnation and melting of the fluid and repeated mechanical stress accelerate the crack propagation.

Therefore, on the one hand, the die casting mold must be fully preheated before it can start.

In addition, in order to avoid early cracking and failure during the production of die-casting molds, a certain operating temperature range must be maintained.

At the same time, it is not a problem to ensure the production and internal reasons before the mold is put into production.

In actual production, mold failure is the most common failure of thermal fatigue cracks.

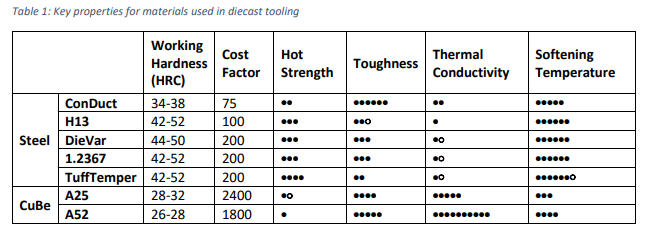

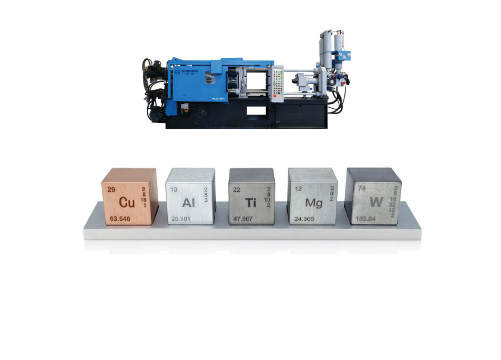

Failure Analysis in Die casting–Tooling materials

- Aluminum alloy

- Zinc alloy

- Magnesium alloy

- Copper alloy

- Steel

- Cemented carbide

- Tool steel

- Special steel

- Cast steel

- Other materials

Aluminum alloy

Commonly used grades are ADC12, YL113, YL102, A380, A360, etc.

Among them, ADC12 is the most commonly used aluminum alloy.

Which has good die-casting formability, machinability and mechanical properties,Other commonly used grades include ALSi10Mg, ALMg5, etc.

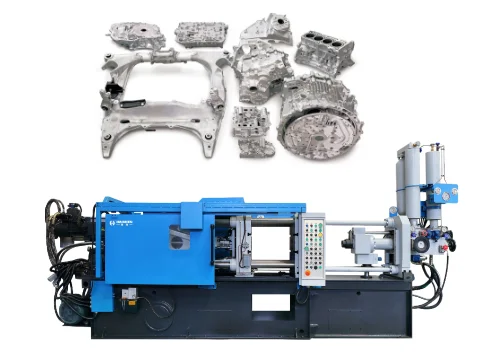

Haichen’s die casting machines can process all types of aluminum alloys, and we test the mold after designing the die casting until the customer is satisfied.

Different die castings use different alloys, if you can’t confirm, you can contact Haichen to help you make a decision.

We have a lot of experience in the design and production of a variety of die castings, such as road studs or heater heat sinks.

Zinc alloy

Commonly used grades are 3#Zn. Zinc alloy die material is suitable for small die casting production, but the toughness is poor.

Magnesium alloy

Magnesium alloy die materials are suitable for precision die casting molds and mass production, with low density, high strength and good thermal conductivity.

Copper alloy

Copper alloy die material is suitable for high-precision die production, with high hardness and good wear performance.

Steel

Commonly used grades are 45# steel, 50# steel, Cr12MoV steel, etc. Steel die materials with high strength, good toughness and excellent processing properties, suitable for manufacturing large and heavy die-casting molds.

Cemented carbide

Brands are WC-Co, TiC-Ni and so on.

Cemented carbide is used to manufacture surface coatings for cavities and cores to improve wear and corrosion resistance.

Tool steel

Commonly used brands are SKD61, DH-31, 8407, 8418, H13, 3Cr2W8V, 4Mo5CrSiV and so on.

Tool steel mold material has high hardness, wear resistance and fatigue resistance, suitable for the production of high requirements of the mold.

Special steel

Including chromium-molybdenum steel, chromium-vanadium steel, etc., with high hardness and good wear resistance, suitable for manufacturing cold stamping dies.

Cast steel

Commonly used grades are QT550, QT600, S50C, etc.

The casting steel mold material has good wear resistance and corrosion resistance, which is suitable for manufacturing large die casting molds.

Other materials

Including ductile iron, medium carbon steel, etc.

These materials have low manufacturing costs and good compressive properties, making them suitable for making smaller die casting molds.

Failure Analysis in Die casting–Die casting process

- Melting metal

- Injection of metal into the mold

- Curing

- Demolding

- Trimming

Melting metal

Heating the metal to its melting point, making it liquid.

This step is usually performed in a furnace to ensure that the metal is heated evenly.

Injection of metal into the mold

Molten metal is injected into the mold cavity under high pressure.

The injection process requires precise control of pressure and speed to ensure that the metal completely fills the mold and forms the desired shape.

High pressures typically range from 1500 to 25000 psi.

Die casting molds are the core of the die casting process, and their design, manufacturing, and application directly impact product quality and production efficiency.

Haichen uses professional software and a professional design team to customize molds for each customer.

Curing

The metal is rapidly cooled and solidified into a solid in the mold.

This process requires maintaining a certain amount of pressure to ensure that the metal is fully cured and formed into the desired shape.

Demolding

When the metal is fully cured, the mold is opened and the casting is removed from the mold.

This step is usually accomplished using a thimble or other mechanical device.

Trimming

Castings may be removed with excess material such as gates, risers, flashes, and trachomets, which need to be cleaned by dressing tools (e.g., dressing knives) or by hand.

Together, these steps ensure the production of high-quality and precise die castings.

Failure Analysis in Die casting–Failure Analysis Types

- Thermal fatigue cracking

- Integral brittleness

- Erosion

- Dissolution

- Sticking mold

- Deformation

- Cracking

- Corrosion

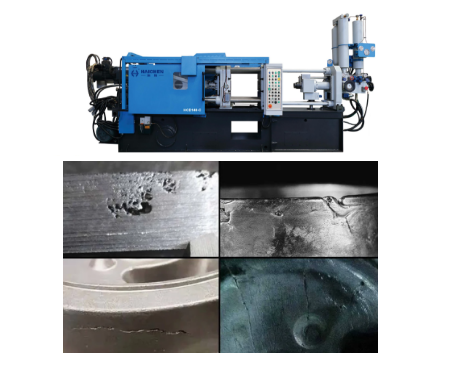

Thermal fatigue cracking

This is one of the most common forms of failure and typically occurs in areas of thermal stress concentration on the surface or inside the mold cavity.

As the number of cycles increases, small holes appear near the crack tip and microcracks gradually form, eventually leading to mold failure.

Integral brittleness

This form of failure is usually catastrophic fracture because of a defective material or improper handling. Integral brittleness often occurs when mechanical or thermal loads are suddenly excessive.

Erosion

The friction and impact of high-speed and high-pressure molten metal and the mold surface will cause the mold surface to wear.

Forming a pit-like irregular surface, and the aggregation is distributed in a granular irregular manner.

Erosion usually occurs at sites where the near-gate temperature is high and the metal hydraulic injection rate is fast.

Dissolution

When the mold comes into contact with the molten aluminum alloy, the chemical reaction produces brittle iron-aluminum compounds, resulting in mechanical abrasion on the mold surface.

Dissolution usually occurs at the point where the mold comes into contact with the molten metal.

Sticking mold

Due to the large temperature fluctuation of the mold surface, the phenomenon of mold sticking, erosion, thermal fatigue and so on is more obvious.

Sticking usually occurs at a higher temperature on the surface of the mold and a slower cooling rate.

Deformation

When the mold is working under high pressure, it is easy to deform due to extrusion and friction. Deformation usually occurs in the weak parts of the mold, such as the gating system, the overflow system, etc.

Cracking

Cracking is usually because impact loads, with mold processing defects and insufficient material properties being the main causes.

Usually occurs in weak parts of the mold, such as gate lines, unpolished parts of the electromachining marks.

Corrosion

When the mold comes into contact with different metal materials, it causes corrosion due to chemical reactions.

Corrosion usually occurs in places where there are soft spots on the surface of the mold.

Such as when the aluminum alloy mold comes into contact with materials such as zinc alloy, magnesium alloy, copper alloy, etc.

Through failure analysis, we can better understand the failure mechanism of molds and castings in the die casting process.

So as to take effective prevention and improvement measures to improve the service life of molds and the quality of castings.