Top 10 Die Casting Companies in South Africa:

- Cape Metal Pressings

- Wahl Industries

- AG Die Casting

- Kingfisher Metal Pressings Cc

- Reliable Pressings & Engineering

- Alternative Structurers (Pty) Ltd

- Unilam Pressings (PTY) Ltd

- Yenza Manufacturing (PTY) Lt

- Copalcor (Pty) Ltd

- ArcelorMittal South Africa Ltd

South Africa is located at the southernmost tip of Africa, with an area of approximately 1.219 million square kilometers and a population of about 60 million.

Its economic structure is dominated by the service industry, accounting for 61% to 65% of GDP, followed by manufacturing and mining.

Mining is a traditional pillar industry, but its proportion has declined in recent years.

The manufacturing industry, especially the automotive industry, is relatively developed.

Furthermore, South Africa has good infrastructure, but its power supply is unstable and there is a significant economic polarization.

Die casting is a part of manufacturing, especially in the automotive industry.

The automotive industry in South Africa holds an important position in Africa, accounting for 80% of the total output in Africa.

International companies such as Toyota have production bases in South Africa, and the government promotes an increase in the proportion of local procurement.

For example, the “South African Automotive Master Plan” plans to raise the proportion of local procurement from 39% to 60%.

The upstream of the die-casting market involves raw materials.

South Africa is rich in mineral resources, especially platinum group metals, chromium, manganese, etc.,

Which may be helpful for the supply of metal materials required for die-casting, such as aluminum and magnesium alloys.

In addition, magnesium alloy die-casting has potential in lightweighting.

Although the output of brucite in South Africa is not high, the application of related technologies.

Such as semi-solid die-casting technology may bring about efficiency improvements.

Cape Metal Pressings

Cape Metal Pressings is a well-known local metal die-casting and stamping manufacturing enterprise in South Africa.

Its headquarters is located in Cape Town, Western Cape Province.

And it focuses on the production of automotive parts, industrial equipment components and customized metal products.

For example, engine mounts, transmission cases, hydraulic valve bodies, precision hardware parts, etc.

As an important player in the local die-casting field in South Africa, CMP, together with enterprises.

Such as UNILAM PRESSINGS, jointly supports the localization demands of the domestic manufacturing industry, especially occupying a position in the automotive industry chain.

Benefiting from the South African Automotive Master Plan (SAAM) policy, the company has participated in increasing the localization rate of automotive parts (target 60%), reducing its reliance on imports.

Wahl Industries

Wahl Industries is one of the leading metal processing and die-casting enterprises in South Africa.

Its headquarters is located in Gauteng Province (the industrial core area of South Africa).

It was established in the 1970s and focuses on precision die-castings, metal stamping parts and component assembly.

Its service areas cover automotive manufacturing, electronic equipment, household appliances and industrial machinery.

Including local South African automakers (such as Ford and Nissan), international electronics brands (such as Samsung South Africa), mining equipment suppliers (such as Sandvik), and home appliance enterprises.

AG Die Casting

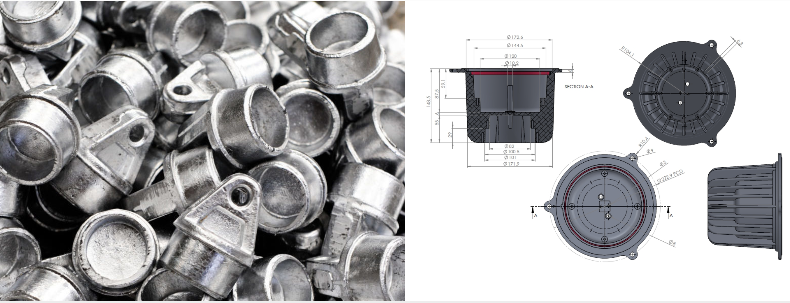

Established in 1980 and located in Gauteng Province, South Africa, AG Die Casting is equipped with medium and large-sized die-casting machines.

Support full-process services from prototype development to mass production, with an annual production capacity of up to hundreds of thousands of pieces.

In fact, AG Die Casting focuses on the manufacturing of die-castings in the fields of automotive parts.

And mining equipment and is a key player in the local die-casting industry in South Africa.

We provide die-castings made of materials such as aluminum alloy and zinc alloy to meet the requirements of lightweight and high strength.

It includes post-processing services such as TIG welding, heat treatment (such as age hardening).

And surface treatment (spraying, electroplating), forming a “one-stop” solution.

Kingfisher Metal Pressings Cc

Kingfisher Metal Pressings Cc is a regional metal die-casting and stamping parts manufacturing enterprise in KwaZulu-Natal Province, South Africa.

It focuses on providing customized metal processing services for the local industrial market and its operation history may exceed 20 years.

It belongs to the backbone of South Africa’s domestic manufacturing industry.

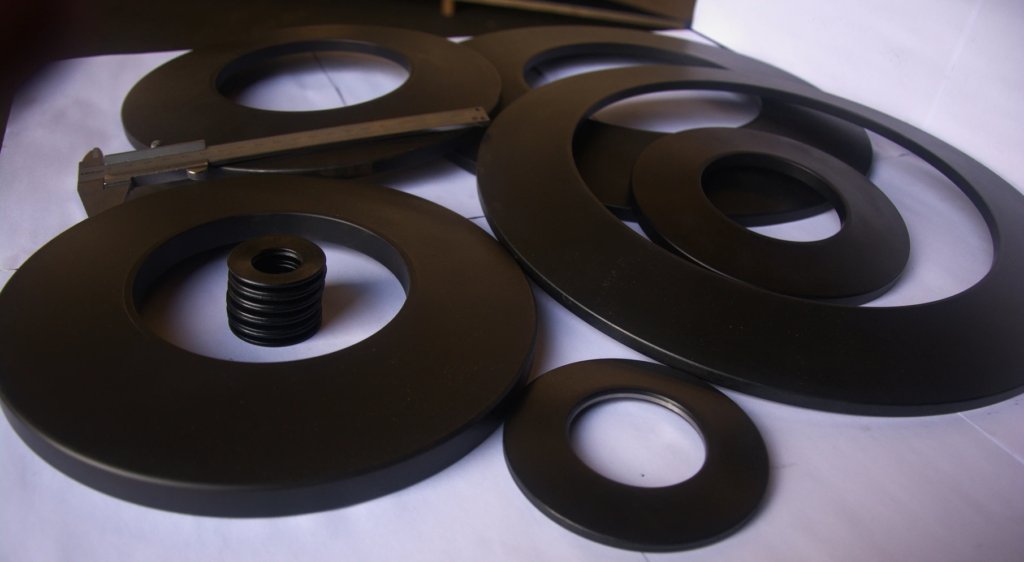

The main business includes metal stamping parts such as automotive components (such as brackets, connectors), home appliance components (such as casings, heat sinks), and general industrial metal parts.

Among them, the die-casting business mainly focuses on die-casting of aluminum alloys and zinc alloys.

And may involve the production of small and medium-sized die-castings (clamping force range: 100-1000 tons).

Reliable Pressings & Engineering

It is a long-established metal processing enterprise in South Africa, founded in the 1980s, with its headquarters located in Durban, Kwazulu-Natal Province.

The company focuses on medium and large-sized metal die-casting parts, structural parts stamping and engineering solutions.

Mainly serving the fields of heavy machinery, mining equipment, agricultural machinery and construction engineering.

In the field of die-casting, we mainly provide wear-resistant parts for mining machinery.

Such as crusher liners, structural parts for engineering vehicle chassis, and die-cast parts for large hydraulic cylinder blocks, etc.

The core customers include local mining giants in South Africa (such as Sibanye Stillwater and AngloGold Ashanti), construction Equipment manufacturers (such as Bell Equipment), and agricultural machinery enterprises (such as the South African branch of John Deere).

RPE is a leading supplier of heavy equipment die-casting parts in South Africa.

With its R&D capabilities in large-tonnage die-casting equipment (such as die-casting machines with a capacity of over 2500T) and anti-wear materials.

It holds approximately 20% of the market share in the mining equipment parts market.

In response to South Africa’s “local procurement” policy (such as the requirement of the Mining Charter that mining companies purchase 60% of local products), become a key player in the mining supply chain.

Alternative Structurers (Pty) Ltd

Alternative Structurers (Pty) Ltd is one of the registered enterprises in the metal die-casting industry in South Africa, with its headquarters located in the Centurion District of Gauteng Province.

Centurion is an emerging technology and industrial center in Gauteng Province, gathering enterprises in automotive parts, mechanical manufacturing and engineering services.

Serve the vehicle manufacturers or Tier 1 suppliers in the neighboring Pretoria (a major automotive manufacturing hub in South Africa).

Alternative Structurers adopt domestic or second-hand imported equipment and support multi-variety and small-batch production.

Provide small and medium-sized aluminum alloy/zinc alloy die-castings for mining equipment (such as hydraulic valve bodies) or construction machinery.

Small and medium-sized die-casting enterprises in South Africa are usually equipped with medium-sized die-casting machines with a clamping force of 100 to 800 tons, and the materials are mainly aluminum alloys.

Unilam Pressings (PTY) Ltd

Unilam Pressings (PTY) Ltd is an influential local metal die-casting and stamping manufacturing enterprise in South Africa.

It was established in 1985 and its headquarters is located in Johannesburg, Gauteng Province.

The company focuses on automotive parts, industrial equipment components and customized metal die-castings.

With service areas covering automotive manufacturing, mining machinery, electronic equipment and consumer goods packaging.

As a backbone force in the die-casting industry of South Africa, Unilam Pressings plays a key role in the localization of the automotive industry chain.

The local procurement rate of its products has increased to more than 45% as required by South Africa’s “Automotive Master Plan (SAAM)”.

And it has been listed as a “Technology Demonstration Enterprise” by the National Foundry Technology Network (NFTN) of South Africa. Promote industry automation and skills training.

Yenza Manufacturing (PTY) Ltd

Yenza Manufacturing (PTY) Ltd is located at Comsec Complex, Old Grahamstown Rd, Sydenham, Port Elizabeth, Eastern Cape Province, South Africa, 6001.

Port Elizabeth is one of the core areas of the Automotive industry in South Africa, gathering vehicle manufacturers.

Such as Volkswagen and Ford, as well as Tier 1 suppliers (such as Continental Automotive).

The location advantage of Yenza Manufacturing is significant and it can respond quickly to local demands.

Metal Pressings of Yenza Manufacturing (PTY) Ltd is a midstream enterprise in South Africa’s manufacturing industry, serving the automotive, industrial equipment and regional supply chains.

Including automotive body structural components (such as brackets, chassis assemblies), industrial equipment casings, etc.

At the same time, flexible production involving small-batch orders, such as mining machinery parts or construction hardware.

Copalcor (Pty) Ltd

Copalcor (Pty) Ltd is a leading metal manufacturing group in South Africa, with business covering steel production, casting, processing and distribution.

It is one of the largest suppliers of cold-rolled steel, galvanized steel and stainless steel in South Africa.

We offer metal processing services, including stamping, extrusion, welding and other processes, providing metal semi-finished products and components for the construction, automotive and home appliance industries.

The casting business mainly focuses on sand casting and centrifugal casting, producing large industrial castings (such as pipes and valves).

ArcelorMittal South Africa Ltd

ArcelorMittal South Africa Ltd is one of the largest steel manufacturers in Africa, with its business core focusing on steel smelting and processing.

Affiliated with the global steel giant ArcelorMittal (the world’s largest steel enterprise).

The South African subsidiary was established in 2006, with its headquarters located in Johannesburg.

It operates major steel mills in South Africa (such as Vanderbijlpark and Newcastle plants), producing hot-rolled steel, cold-rolled steel, galvanized steel and long products (such as rails and sections).

Steel products are mainly carbon steel and stainless steel, and the casting types are mainly sand casting and centrifugal casting.

Which are used to produce wear-resistant parts for mining machinery or building structural parts.

Provide steel base materials (such as die steel) for die-casting enterprises for the manufacturing of die-casting molds.

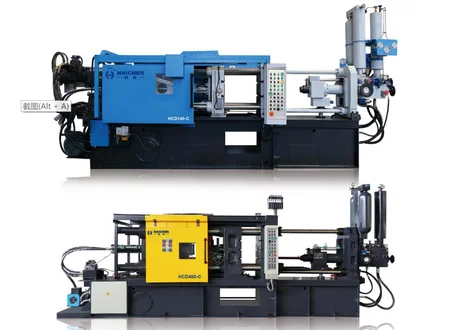

Ningbo Haichen machinery

Ningbo Haichen machinery was founded in 2005, Located in Ningbo, Zhejiang, China.

HAICHENspecializes in the production and sale of hot chamber die-casting machines, cold chambeldie-casting machines, servo die casting machines, magnesium alloy die casting machines and relative auxiliary equipment.

HAlCHEN always places more emphasis on the technology and management.

Because of its advanced technology, high quality and effective management, “HAlCHEN”‘s hot chamber as well ascold chamber die-casting machines has won the trust from our clients at home and abroad.