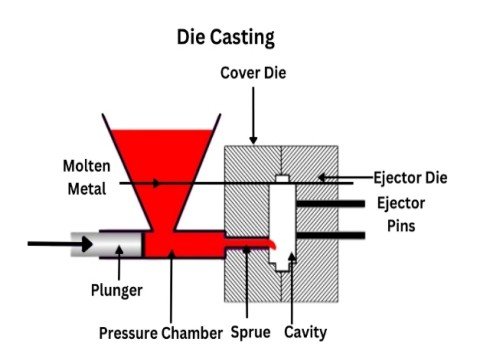

Die casting heating bush types includes high-frequency induction heating bush, electric Heating bush, hot runner heating bush and so on.

In a die casting machine, a heating bush is a device uses to increase the temperature of the mold. It ensures that the molten metal reaches the appropriate temperature when it is injected into the mold.

Depending on different application requirements and material properties, heating bushes have following 5 main types:

High-frequency induction heating bush

This type of heating bush uses a high-frequency electromagnetic field to heat the mold.

For example, in some die-casting machines, a high-frequency induction coil places on the outside of the metal plunger. It uses to heat the plunger through electromagnetic induction, thereby indirectly heating the mold.

Temperature Control and Uniformity

The heating sleeve (heating bushing) maintains consistent mold temperature, ensuring uniform solidification of the molten metal, reducing casting defects (such as porosity) and improving surface quality.

Applicable Metals

Particularly suitable for aluminum die casting, but also for high-melting-point alloys such as copper.

Preheating and Localized Heating

Used for preheating the mold (such as the nozzle area) before die casting, or for locally heating specific components (such as pins) to assist in processes such as riveting.

Technical Advantages

- Efficient and Energy-Saving: Heat is generated directly within the workpiece, resulting in high thermal efficiency and rapid temperature rise.

- Precise Temperature Control: Avoids the temperature fluctuations associated with traditional heating (gas/resistance heating). Cooling can be combined with compressed air or water cooling systems.

- Automation Compatibility: Easily integrated into automated production lines

Electric Heating bush

These heating bushes usually heat by resistive heating elements such as heating rods or tubes. The heating elements can embed inside or outside the mold to evenly heat the mold surface.

Cast Aluminum Heating Jacket

- Material and Process: Made of a high-purity aluminum alloy shell with an embedded heating element, formed via die-casting or casting.

- Operating Characteristics:

- Temperature Range: 150–450°C.

- Advantages: Long life, excellent heat retention, high mechanical strength, and resistance to magnetic field interference.

- Applications: Plastics machinery, cable equipment, chemical, and petroleum industries.

Cast Copper Heating Jacket

- Material and Process: Die-cast from a high-purity copper block with embedded heating elements.

- Operating Characteristics:

- Higher Temperature Resistance: Up to 650°CTemperature Uniformity: Precision machining ensures a tight fit with the mold, minimizing heat loss.

Hot runner heating bush

In some hot chamber die casting machines, heating bushes may be integrated into the hot runner system to heat the melt channel. And the mold entrance area to ensure that the melt reaches the appropriate temperature before entering the mold.

Externally Heated

A heating element (such as a coil or band heater) is wrapped around the outside of the runner sleeve and heats the molten metal through heat conduction.

The application of coil and band heaters is described as suitable for hot runner tips in magnesium alloy die casting.

A heater design with a copper alloy and stainless steel housing is mentioned, which optimizes heat transfer and withstands temperatures up to 649°C.

Internally Heated

A resistance heater is embedded directly into the melt channel (commonly seen in plastic injection molding).

This design states that the material is heated by internal resistance, but does not explicitly mention its application in metal die casting.

Water Cooling/Heating bush

This type of heating bush regulates the mold temperature through a water circulation system.

In some cases, cooling water can also be used to cool the mold, thereby achieving precise temperature control.

Water Cooling System

Mechanism: Cooling water circulates through channels within the mold (typically maintained at a temperature of 10–30°C using a chiller), directly absorbing heat from the bushing and mold.

- Applications:

High-volume die casting (e.g., automotive parts) where water’s high heat transfer efficiency allows for rapid temperature reduction. - Applications requiring uniform cooling, such as preventing overheating of plunger tips or spool bushings.

Oil Heating System

Mechanism: Circulates thermal oil (up to 350°C) through the mold channels, providing a stable high-temperature environment.

- Applications:

High-temperature alloy die casting (such as magnesium alloys, which require temperatures of 200–300°C). - Differentially heated parts are locally adapted to meet specific casting structural requirements.

Advantages and Limitations:

Excellent high-temperature stability, reducing the risk of mold cracking, but presents a fire hazard and is complex to maintain.

Laser heating sleeves

Although less used at present, laser heating technology has also been studied for local heating of mold surfaces. This method can achieve fast and precise temperature control.

Resistance Heating (Heating Tubes)

Composite sleeves (such as beryllium copper-H13 material) achieve zoned temperature control through built-in heating tubes (cartridge heaters). Due to their compact size and wide compatibility, they are considered the preferred solution.

Potential Challenges of Laser Heating

Technical Compatibility:

The sleeve must withstand high-pressure injection (the thrust must be borne by the fixed platen) and concentric components must be prevented from contacting the molten metal.

Direct laser heating of the sleeve could result in heat concentration, leading to deformation or material failure.

The design and selection of these heating jackets depends on the specific needs of the die casting machine, the type of metal used, and the thermal properties of the mold material. For example, for high-temperature metals (such as magnesium alloys), it may be necessary to use a heating jacket made of high-temperature resistant alloy steel or special materials to ensure the stability and life of the mold at high temperatures.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine.They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts. When you have any demand, feel free to contact us.