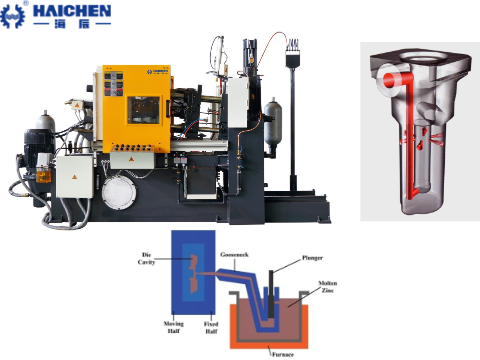

Hydraulic valves are critical components in die casting systems, enabling precise control of fluid flow, pressure, and direction.In die-casting equipment, hydraulic systems are an integral part of the process, ensuring high-quality part production within cost limits.

However, with increasing technology and automation, the way hydraulic circuits interact with electromechanical and PLC processes has become increasingly complex. Troubleshooting and maintaining hydraulic components are crucial to the successful daily operation of die-casting equipment.

This webinar is designed to help you understand and apply hydraulic principles.

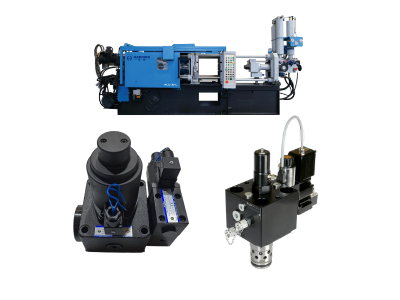

Common die casting system hydraulic valves

Haichen designed various VALVES for different functions to achieve precise control of the equipment.

Key valve types and their roles include:

- Directional Control Valves

- Pressure Control Valves

- Flow Control Valves

- Cartridge Valves

- Vacuum Valves

- Specialized Valves

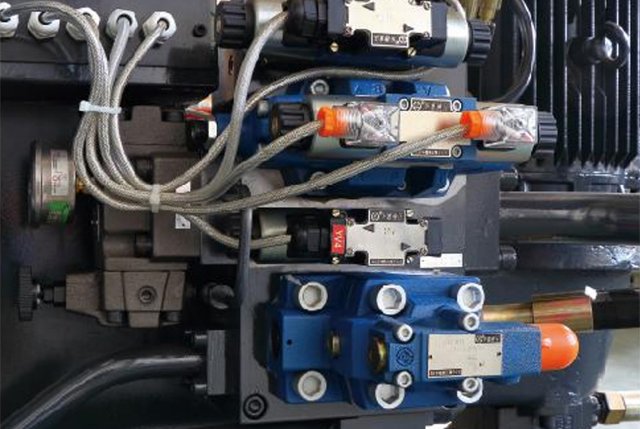

Directional Control Valves

- Function: Control the direction of hydraulic fluid flow to actuators (e.g., hydraulic cylinders).

- Types:

- Manual/Solenoid Valves: Such as 3-position/4-way solenoid valves (e.g., electrohydraulic valves for switching flow paths).

- Proportional Directional Valves: High-precision valves (e.g., Rexroth 4WR/4WRA series) that adjust flow and direction via electrical signals.

- Servo Valves: High-response valves (e.g., Moog servo valves) for closed-loop systems requiring dynamic control.

Pressure Control Valves

- Function: Regulate system pressure to ensure safety and meet process requirements.

- Types:

- Proportional Pressure-Reducing Valves: Adjust pressure dynamically via electrical signals (e.g., during injection stages).

- Accumulator Discharge Valves (e.g., TEA series): Release stored high-pressure fluid rapidly for fast injection.

- Safety/Relief Valves: Emergency pressure relief or flow cutoff (e.g., CV1-type valves).

- Sequence Valves (e.g., HAWE CDK series): Control the order of actuator movements.

Flow Control Valves

- Function: Adjust flow rate to control actuator speed.

- Types:

- Proportional Throttle Valves: Enable stepless flow adjustment via electrical signals.

- Needle Valves: Fine-tune small flows (e.g., in vacuum systems or auxiliary circuits).

Cartridge Valves

- Features: Modular design for easy integration and maintenance.

- Applications:

- High-Speed Injection Cartridge Valves: Large-diameter valves for rapid injection.

- Closed-Loop Servo Cartridge Valves: Combine sensors for precise flow/pressure control.

Vacuum Valves

- Function: Manage mold cavity vacuum to reduce porosity in castings.

- Types:

- Hydraulic Vacuum Valves: Synchronize with injection to prevent molten metal clogging.

- High-Vacuum Shutoff Valves: Rapidly seal exhaust channels for airtight reliability.

Specialized Valves

- Proportional-Servo Hybrid Valves: Combine pressure, flow, and directional control for complex processes.

- Miniature Pressure Valves (e.g., MVG/MVE series): Compact valves for harsh conditions (vibration, high temps).

Key Applications

- Injection Stage: Accumulator valves provide burst flow; proportional valves ensure speed accuracy.

- Pressure Holding Stage: Proportional pressure valves maintain constant pressure to prevent shrinkage.

- Vacuum Assistance: Vacuum valves evacuate air before injection, minimizing gas defects.

- Safety: Relief valves and shutoffs protect against overpressure.

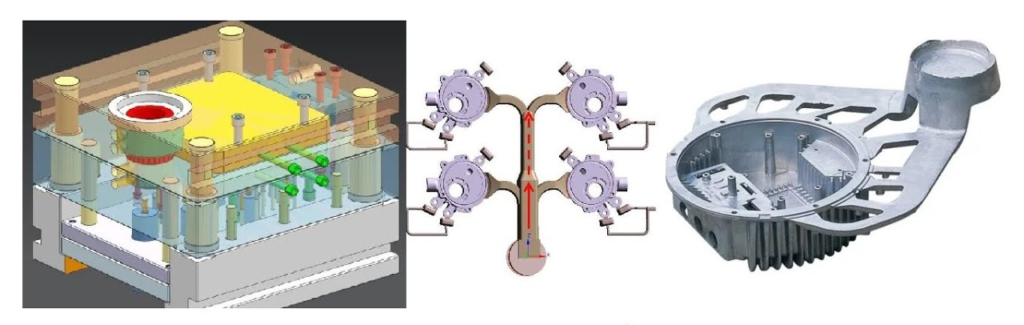

Materials & Manufacturing

- Valve Bodies: Aluminum alloys (e.g., ADC12, A390) for lightweight, corrosion-resistant designs.

- Process: Die casting ensures complex geometries and precise internal flow channels.

How does the hydraulic directional valve of a die casting machine work?

The hydraulic directional valves in die casting machines operate based on the relative movement between the valve spool and valve body. They use electromagnetic or hydraulic signals to control oil flow direction and on/off states, enabling critical actions like mold clamping and injection. The working principles are as follows:

- Basic Structure and Operation

- High-Flow and Rapid-Response Design

- Two-Stage Valves and Pilot Control

- Safety and Critical Functions

Basic Structure and Operation

- Core components: Valve spool and body.

- Neutral position: When the solenoid is de-energized, the spool remains centered under spring force (e.g., in an O-type neutral configuration), blocking all ports and keeping the system static.

- Activated state: When energized, the solenoid moves the spool to redirect oil flow. Examples:

- Mold Clamping: Energizing solenoid 3YA opens valve 21, allowing pressurized oil to enter the mold clamping cylinder’s rodless chamber, driving the piston forward. Oil in the rod chamber returns to the tank via cartridge valve 17.

- Injection Process:

- Slow injection: Energizing 8YA opens valve 19, directing high-pressure pump oil to the injection cylinder’s right chamber.

- Fast injection (two-stage):

- Stage 1: Energizing 9YA combines pump oil with accumulator 31 for rapid flow.

- Stage 2: Energizing 10YA further boosts speed via accumulator 22.

High-Flow and Rapid-Response Design

- Cartridge valves (e.g., valve 34 for fast injection) handle extreme flow rates (up to 4200 L/min), critical for quick mold filling.

- Accumulators (e.g., 31 and 22) supplement pump flow during peak demand, ensuring rapid oil delivery to the injection cylinder.

- Direct pilot control: Fast-acting valves eliminate large pilot valves, reducing response time.

Two-Stage Valves and Pilot Control

For high-pressure/high-flow applications:

- Pilot stage: Small solenoid valves (e.g., valve 35) control pilot oil to drive the main valve spool.

- Example: Energizing 11YA opens pilot valve 35, allowing accumulator 30 to pressurize the intensifier via main valve 42.

- Benefits: Reduces solenoid force requirements and enhances reliability.

Safety and Critical Functions

- Pressure retention: Check valves (e.g., valve 29) prevent core retraction during injection.

- Backpressure reduction: Pilot-operated check valves (e.g., valve 38) lower resistance in return lines during fast injection.

- Pressure regulation: Relief valves (e.g., valve 18) set low-pressure thresholds for mold clamping safety.

Hydraulic directional valves in die casting machines use electromagnetic or hydraulic signals to switch oil paths precisely. By integrating cartridge valves, accumulators, and two-stage control, they meet demands for high pressure, extreme flow, and rapid response, while safety valves and check valves ensure system stability.

Overall

Hydraulic valves in die casting systems work synergistically to balance speed, precision, and safety. Proportional/servo valves excel in high-accuracy tasks, cartridge valves enable rapid movements, and vacuum valves optimize casting quality. Advanced materials and die casting techniques further enhance performance and durability.

Contact Haichen by letter to get more technical support on die casting at any time.