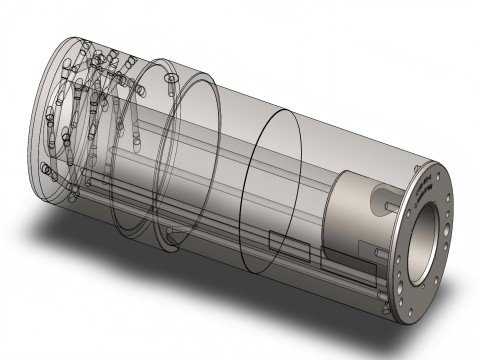

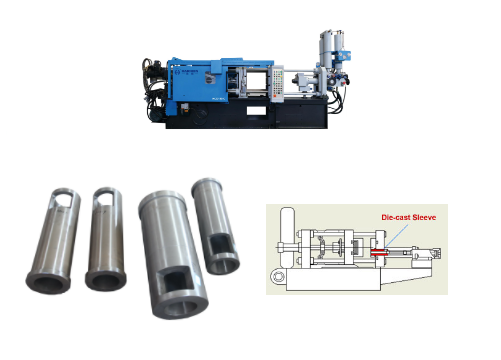

Plunger tips for die casting are component utilised within the injection sleeve of a die-casting machine. It is designed to regulate the flow of molten metal into the injection sleeve, ensuring precise casting production and minimising defects. These are typically custom-engineered for specific die-casting machine models and come in various shapes and sizes to accommodate different casting applications.

Material requirements for plunger heads can be exceptionally demanding, as they must withstand associated high temperatures and pressures. As a vital component within the die-casting machine’s injection sleeve, adopting optimal solutions for plunger heads enhances final product quality and reduces downtime.

Plunger tips for die casting are categorized based on material, design, and application scenarios. Haichen Die Casting introduces their characteristics to you.

Haichen’s key explanation of die casting Plunger Tips

- By Material

- By Design and Function

- By Lubrication Method

- Application Scenarios

By Material

- Steel Plunger Tips:

Predominant in East Asian markets due to lower costs. Steel offers high mechanical strength but weaker heat resistance and thermal stability, leading to shorter service life and frequent replacements. - Copper Alloy Plunger Tips:

Widely used in Europe and North America for superior thermal conductivity and wear resistance. Copper alloys handle high-temperature, high-pressure environments better, minimizing thermal expansion and improving casting quality. Higher costs limit their adoption in East Asia. - Beryllium-Copper (BeCu):

Common in aluminum die casting for its excellent thermal conductivity and wear resistance. However, rapid wear necessitates frequent replacements, driving demand for alternatives like H-13 steel. - H-13 Tool Steel:

High hardness, thermal shock resistance, and lower thermal expansion compared to BeCu. Ideal for long-term stability in aluminum die casting, gradually replacing beryllium-copper. - Specialized Materials:

Includes nitrided steel (Nitralloy 135) and molybdenum alloys (TZM) for extreme conditions (e.g., ultra-high pressure/temperature). Rarely used except for niche or experimental applications.

By Design and Function

- Standard-Size Plunger Tips:

Designed for common die-casting machines. For example, cold-chamber plunger tip diameters typically range from 61–78.7 mm (2.4–3.1 in). - Customized Plunger Tips:

Tailored for specific molds or alloys to optimize sealing and pressure transfer. Often used for complex geometries or specialized alloys.

By Lubrication Method

- Lubricant-Dependent Tips:

Require specialized lubricants (e.g., graphite-containing or lithium-based lubricants like PLUNGER SLICK™) to reduce friction and extend lifespan. - Self-Lubricating Tips:

Made from copper alloys or coated materials to minimize external lubrication needs, ideal for high-speed continuous production.

Application Scenarios

- Hot-Chamber Die Casting:

Used for low-melting-point metals (e.g., zinc, magnesium). Plunger tips must resist prolonged exposure to molten metal, demanding corrosion and heat resistance. - Cold-Chamber Die Casting:

For aluminum, copper, and high-melting-point alloys. Tips endure extreme instantaneous pressure (up to 8,860 psi), requiring high strength and impact resistance.

Key Considerations

Plunger tip selection depends on cost, wear resistance, thermal stability, and process requirements. While copper alloys dominate in the West for efficiency, steel remains cost-effective in East Asia. Advances in materials (e.g., H-13 steel) and lubrication technologies continue to enhance performance and durability.

What material is die casting plunger tip?

The plunger tip in die casting is primarily made of copper alloys, particularly beryllium copper alloys (Cu-Be), with regional variations in material preference. Here’s a detailed breakdown:

- Copper Alloys

- Steel

- Other Materials

Copper Alloys (Dominant in Western Markets)

- Beryllium copper (e.g., C17200) is the industry standard in Europe and North America. Key advantages include:

- High strength (tensile strength up to 1,460 MPa) to withstand extreme pressures (up to 720 bar during injection).

- Superior thermal conductivity for rapid heat dissipation, minimizing thermal expansion and prolonging service life.

- High-temperature stability under molten aluminum temperatures (~700°C).

- Examples include Albaksan Group’s specialized copper alloys and Wieland’s beryllium-free copper solutions (e.g., CaroTec series), which use copper rings to reduce wear on the shot sleeve.

Steel (Common in East Asia)

- Steel remains prevalent in Japan and parts of East Asia due to lower upfront costs. However, it has drawbacks:

- Poorer thermal conductivity, leading to faster thermal fatigue and shorter lifespan compared to copper alloys.

- Increasing adoption of copper alloys in these regions is driven by demands for higher productivity and durability.

Other Materials

- Niche alloys (e.g., nickel-based) are occasionally used but face limitations in cost, machinability, or performance. Beryllium-free copper alloys are gaining traction due to environmental and safety concerns around beryllium processing.

Copper alloys (especially Cu-Be) dominate in Western markets for their balanced strength, thermal management, and durability. Steel remains cost-driven in East Asia but is gradually being replaced. Material selection ultimately depends on cost-benefit analysis, process requirements, and regional preferences.

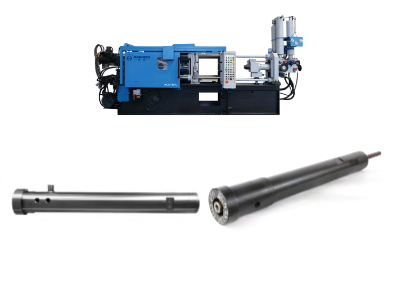

Haichen die casting equipment provides reliable Plunger Tip

Haichen Die-Casting Equipment and Plunger Tip Reliability

While Haichen’s official documentation does not explicitly mention proprietary Plunger Tip technology, its die-casting machines are designed with features that indirectly ensure component reliability. Here’s a concise analysis based on available evidence:

- Material and Manufacturing Standards

Haichen emphasizes the use of high-strength materials (e.g., steel nozzles and gooseneck components) and advanced heat treatment processes. These practices enhance durability in high-temperature environments, which likely extends to critical components like the Plunger Tip. - Indirect Technological Alignment

Industry standards for Plunger Tips (e.g., nitride coatings for wear resistance, modular designs for easy maintenance) align with Haichen’s focus on precision engineering and longevity. For example, imported hydraulic systems and servo-controlled pressure adjustments suggest compatibility with high-performance Plunger Tips. - Comparison with Competitors

Haichen prioritizes system-level robustness. Its machines integrate components from certified suppliers, implying adherence to industry benchmarks for wear resistance and thermal stability.

Haichen’s die-casting equipment may not explicitly advertise proprietary Plunger Tip technology, but its rigorous material selection, manufacturing precision, and reliance on imported critical components (e.g., hydraulic systems) strongly support Plunger Tip reliability.

Welcome to contact Haichen at any time to get more die-casting technical support.