The warning signs of thermocouple failure during die casting mainly including:

- The temperature display is abnormal

- The system alarm is triggered

- The data recording is abnormal

- Alerts in physical condition and maintenance checks

- Indirectly correlated process anomaly signals

Warning signs of thermocouple failure in die casting, as a key temperature monitoring element in the die casting process.

The failure of thermocouple will directly affect the accuracy of mold temperature control, product quality and equipment safety.

Ever had a firing go sideways, even though everything seemed right? If your furnace is heating unpredictably or missing target temps, there’s a good chance your thermocouple is trying to tell you something.

These little metal probes are one of the most critical parts of your furnace’s brain. When they’re off, your firing results will be too.

The good news is: Problems with thermocouples are usually easy to detect. Haichen will help you figure out where to start the troubleshooting process, making it much easier to resolve.

Understanding the role of thermocouples in the furnace

Thermocouples can measure the temperature inside the furnace, so the controller can know when to start, when to cool down, or when to reach the appropriate temperature to safely open the furnace.

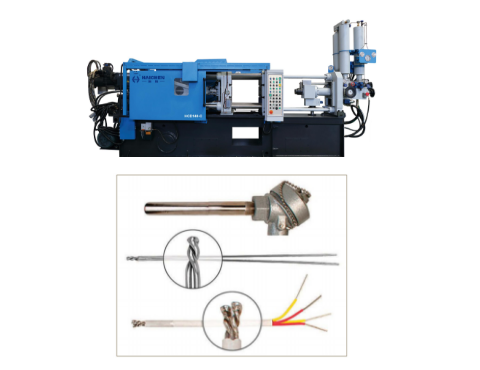

It achieves this function by connecting two different metals at one end. When this connection point heats up, a tiny voltage signal is generated. The controller reads this signal and converts it into a temperature value.

Haichen‘s thermocouples have reliable performance and are affordable. They perform well within the temperature range of approximately 2350°F (1260°C).

Some high-end/high-temperature models use S-type thermocouples, which are more precise and durable at high temperatures (but also more expensive).

No matter which type of thermocouple your furnace uses, one thing is certain: maintaining the good condition of the thermocouple means being able to achieve a more stable and successful firing process.

The temperature display is abnormal

- Unusually high or low temperature values

- Fluctuating or zeroing of temperature data

Unusually high or low temperature values

When the thermocouple is shorted, the compensation wire is mismatched.

Or the thermoelectrode deteriorates, the temperature display value can deviate significantly from the actual value.

For example, a low thermoelectric potential can be caused by a short circuit in the junction box.

Damage to the insulation of the compensating wires, or deterioration of the electrodes.

Fluctuating or zeroing of temperature data

Loose thermocouple wiring, poor contact, or broken guard tube can cause the signal to be unstable.

As the temperature data jumps or fluctuates irregularly.

If the thermocouple is completely disconnected, the temperature may appear at room temperature or at zero.

The system alarm is triggered

Specific Fault Codes: Different die casting machine brands may indicate faults through codes.

Pbr Err/PbS Err (Thermolator Thermostat): Thermocouple faults that point directly to the process return line or supply line.

Over/Low Temperature Alarm: The temperature monitoring system triggers an alarm when the temperature of the thermocouple temperature measurement point exceeds the threshold set by the process or falls below the reasonable range after compensation.

The data recording is abnormal

- Deviation from Expected Temperature Profile

- Compensation failure

Deviation from Expected Temperature Profile

In real-time monitoring systems, thermocouple failure can cause the temperature profile to be out of sync with the mold motion (e.g., irregular fluctuations or stagnation).

Compensation failure

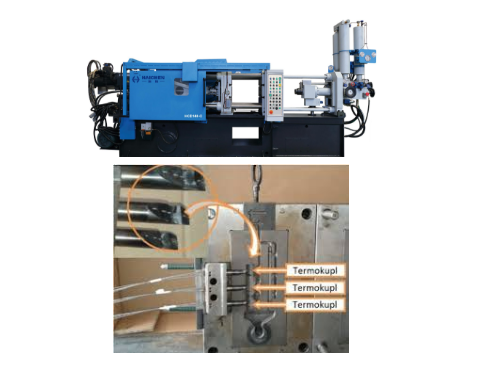

If the distance between the thermocouple probe and the cavity surface is too large (e.g., not installed according to the 25mm standard), persistent deviations may occur even if the temperature compensation is set (e.g., 25°C).

Alerts in physical condition and maintenance checks

- Unusual appearance

- The calibration deviation is outside the allowable range

- Signal impedance abnormality

Unusual appearance

Signs of breakage:Deformation of the protective sleeve, cracks (common in areas washed by molten aluminum).

Or oxidation and discoloration of the armor layer (e.g., bluish surface of Type K thermocouples after long-term use above 600°C).

Risk in die casting scenarios:Broken bushing may lead to infiltration of molten aluminum, causing a short circuit in the thermocouple or contamination of the alloy composition at the measuring end.

The calibration deviation is outside the allowable range

Standard:The normal error should be ≤± 3°C, if the calibration is found to be more than ±5°C.

It needs to be replaced immediately (the plug-in thermocouple calibration cycle is recommended to be every 5000 molds).

Tool recommendation:Use a handheld infrared thermometer or imaging thermometer for comparison and verification.

The cost is 50% lower than that of traditional multiplex testers (such as TP700-16).

Signal impedance abnormality

Detection method:Multimeter to measure thermocouple loop resistance, the normal value should be < 10Ω.

If there is a sudden increase in resistance, it may be due to wire breakage or joint oxidation.

Particularity of die-casting environment:High humidity environment is easy to accelerate the corrosion of terminal blocks.

So it is recommended to use silver-plated joints and check the tightness every month.

Indirectly correlated process anomaly signals

- Shrinkage porosity or cold insulation

- Surface sticking or erosion

- Molded life decreases

- The device is running abnormally

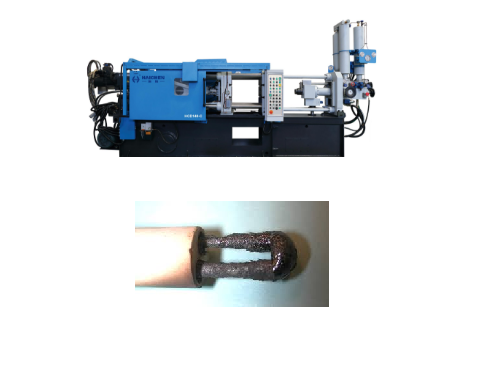

Shrinkage porosity or cold insulation

Thermocouple failures can cause mold temperature to run out of control, which can cause the melt to solidify prematurely or fill incompletely.

Surface sticking or erosion

When the temperature is too high, the surface of the mold is easy to adhere to the molten aluminum, resulting in strain or erosion.

Molded life decreases

Early cracking: After the thermocouple fails, the mold is locally overheated or the temperature gradient increases, which accelerates the generation of thermal fatigue cracks.

Nitride layer spalling: Runaway temperature may cause the reinforcing layer on the mold surface (e.g., nitriding treatment) to peel off due to thermal stress.

The device is running abnormally

Frequent start and stop of the cooling system:If the thermocouple cannot feedback the true temperature, it may cause the mold temperature machine.

Such as the 320°C special oil temperature machine to misjudge and adjust the heating or cooling frequently.

Unstable die casting cycles:Temperature fluctuations can prolong mold opening times or increase scrap rates, indirectly reflecting thermocouple monitoring failures.

Differences in the alarm mechanism of the die casting machine

PLC control: Rely on the operator’s observation of phenomena such as temperature fluctuations, flashing alarm lights.

And comprehensively judge the fault in combination with process parameters such as injection rate and pressure.

PC control: It has a self-diagnosis function, which can directly display fault codes such as open thermocouple circuits and link them to specific monitoring points.

Brand specificity

Brands such as LK/Bühler: Alarm logic (e.g., “thermocouple out-of-range”) may be customized, please refer to the equipment manual to parse the code.

Integrated temperature control system: e.g. the Thermolator TW series, which pinpoints thermocouple faults via codes such as “PBR ERR”.

Small actions, huge impact

When the firing process doesn’t go as expected, you might attribute it to the metal or other factors.

But in many cases, there is a thermocouple working behind the scenes, silently providing incorrect data.

Haichen’s suggestion is to regularly check your thermocouple and address potential problems in advance, so that you can have more confidence in the firing process and ensure the stability of the results.

If your thermocouple malfunctions, please look for a suitable replacement and contact us at any time.

We are also kiln artists ourselves and will do our best to assist you to ensure everything runs smoothly.