Casting parts for die casting machines are metal parts manufacturers produce via the die casting process.

Die casting is a metal casting process where manufacturers inject molten metal into a mold cavity under high pressure, and it widely produces parts with complex geometries and high precision requirements.

Manufacturers can make these castings from a variety of metals, including aluminum, zinc, magnesium, copper and other such alloys.

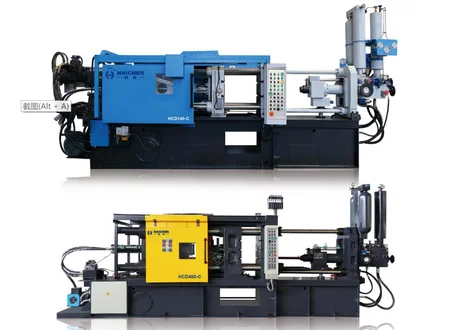

Die casting machine

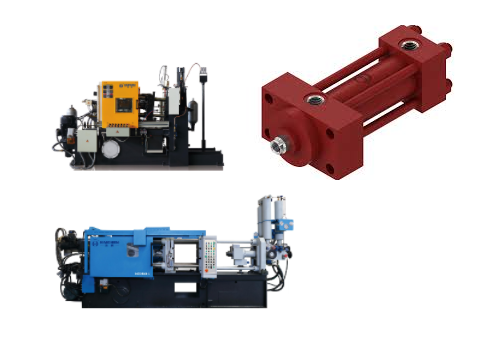

Haichen Machinery is a globally leading manufacturer of high-pressure cold chamber semi-solid state aluminum and zinc die casting, covering a range from 16 tons to 2,080 tons, all equipped with servo hydraulic injection systems.

Our factory sits in Ningbo, China, close to the port, boasting complete facilities and the capacity to provide comprehensive support for sales, services, component supply, and customer training.

Our global manufacturing capabilities and world-class technical level, as well as our long history of leading innovation, reliability.

And precision in the industry, make us the most reliable and experienced partner to meet your die casting machine requirements.

All of Haichen’s complete series of machines can meet the three performance requirements of die casting machines: easy operation, short production cycle, and the ability to achieve high-quality casting of thin-walled and structural components.

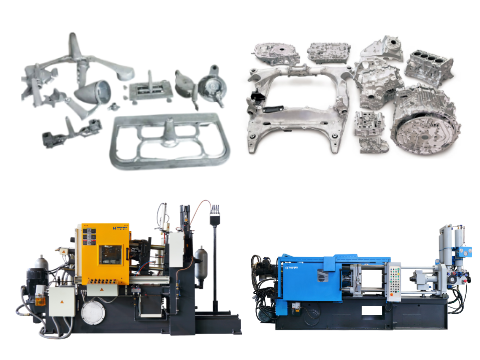

Casting parts for die casting machine

How are castings (widely used in various products) manufactured? To produce castings, a mold is required.

Haichen has a professional team that will design and manufacture molds.

Then, we select the right number of mold cavities and casting machines based on the customer’s production volume and requirements.

During the actual manufacturing process of the casting components, this process includes obtaining raw materials, melting the raw materials, pouring them into the casting machine, trimming, deburring, inspection, and then performing subsequent processing to produce the final cast products.

Trimming refers to the process of removing non-product parts from the casting.

This can be accomplished using equipment such as trimming machines or can be done manually. Deburring is the process of removing “casting burrs” formed at the mold parting lines.

This step aims to remove unnecessary protrusions and complete the surface treatment of the product.

The materials removed during the trimming process are considered as rework materials and are reused as raw materials.

All the machines needed for the entire process can be provided by Haichen.

Motorcycle casting parts

Die-casting motorcycle parts are crucial components in motorcycle manufacturing.

They are produced with high precision and efficiency through the aluminum alloy die-casting process.

The materials, techniques, and applications of these parts widely cover various systems of motorcycles, while relying on advanced mold design and quality control technologies.

Such as motorcycle crankcase body body, crankshaft box, clutch cover, lamp cover, crankcase front cover, transition box, power cover, motor, motor accessories, etc.

Household appliances and electronic casting parts

Manufacturers widely use the die-casting process to make the shells and internal components of household appliances.

Such as the shells of washing machines, the internal structures of refrigerators, and the supports of air conditioners, etc. due to its high precision, high durability and significant cost-effectiveness.

Aluminum cookware such as baking pans, the bottom plates of electric irons, and appliance accessories.

The die-casting process produces drum-shaped supports for washing machines, for instance, which are lightweight, wear-resistant and easy to clean.

Die-casting forms washing machine motor shells, range hood motor fans and other such components in one piece, cutting down on processing costs.

Construction and decoration accessories

In the Haichen case, we customize zinc die-cast decorative accessories—including zinc alloy hardware like buttons, signs and decorative pieces—and use them for decorative applications.

There are also door and window accessories. Aluminum alloy castings are widely used in door and window accessories, such as door handles, hardware locks, hinges, etc.

These accessories are not only aesthetically pleasing but also have the characteristics of corrosion resistance and wear resistance.

Mechanical parts

- Gear: The die-casting process can produce gears with complex shapes. Its high strength and wear resistance make it a staple in mechanical transmission systems.

- Bearings: The high strength and wear resistance of die-cast parts make them suitable for manufacturing key components such as bearings.

- Engine blocks/cylinder heads: Die-casting technology can produce core automotive components such as engine blocks and cylinder heads due to its high precision and ability to handle complex shapes.

- Transmission housings: Die-casting produces complex structural components like transmission housings to meet the requirements of mechanical manufacturing.

- Automotive parts: Including die-cast automotive parts, engine pipe fittings, cylinder heads, valve rocker arms, etc.

- Enclosures and brackets: Die-casting creates complex, high-precision components like enclosures and brackets for the electrical appliance and medical equipment fields.

- Bearings, couplings: Die-casting technology can produce precision mechanical components such as bearings and couplings. Other mechanical components, such as pump housings, valves, and hydraulic system components, are all manufactured through die-casting technology.

Cylinder block and cylinder head

Die casting is a common casting process that manufacturers widely use to produce metal parts like cylinder blocks and cylinder heads.

Manufacturers produce cast aluminum engine blocks and aluminum blocks using die-casting technology.

These are the engine’s core components, and manufacturers typically make them with aluminum or magnesium alloy die-casting to ensure the engine is lightweight and durable.

Pistons

Pistons are also one of the most important components in an engine, and high precision and consistency can be achieved through the die-casting process.

Driveline components, such as driveshafts, gearboxes, etc., which require high strength and durability, and the die-casting process can meet these requirements.

Chassis parts

Including A/B pillars, shock towers, longitudinal members, cross members, subframes, etc., these components play a key role in the structural strength and safety of the vehicle.

Suspension system components

Such as spring seats, shock absorbers, etc., which have a direct impact on the handling and comfort of the vehicle.

Battery Housing

The demand for lightweight and high performance in new energy vehicles has driven the application of die-casting technology in battery housings.

Motor housing

The motor housing needs good heat dissipation performance and structural strength.

And the die-casting process can provide a high-quality finished product.

Braking system components

Such as brake discs, brake calipers, etc., which are essential for the safety of the vehicle.

Wiper system components

Such as wiper arms, wiper motors, etc., these components need good durability and reliability.

Phone case

Many smartphones come with aluminum alloy or zinc alloy die-cast cases to ensure their beauty and durability.

Laptop housing

The enclosure of a laptop is typically manufactured using a die-casting process to achieve lightweight and high strength.

Camera housings

Camera housings require excellent sealing and durability, and the die-casting process delivers high-quality finished products.

Speaker components: such as speaker housings, amplifier housings, etc., which require good acoustic performance and mechanical strength.

Connector housings

Manufacturers typically make connector housings for electronic devices using a die-casting process to ensure the housings’ electrical properties and mechanical strength.

Comprehensive application case Volkswagen AG

The company uses the die-casting process to manufacture the engine blocks and transmission housings of many vehicle models,

which not only improve the performance and reliability of the vehicle, but also significantly reduce the overall weight of the vehicle, thereby improving fuel economy and emissions performance.

New energy vehicles

With the rapid development of the new energy vehicle market, die-casting technology is more and more widely used in key components such as motor shells and battery pack shells,

which further promotes the technological progress and market expansion of the die-casting industry.