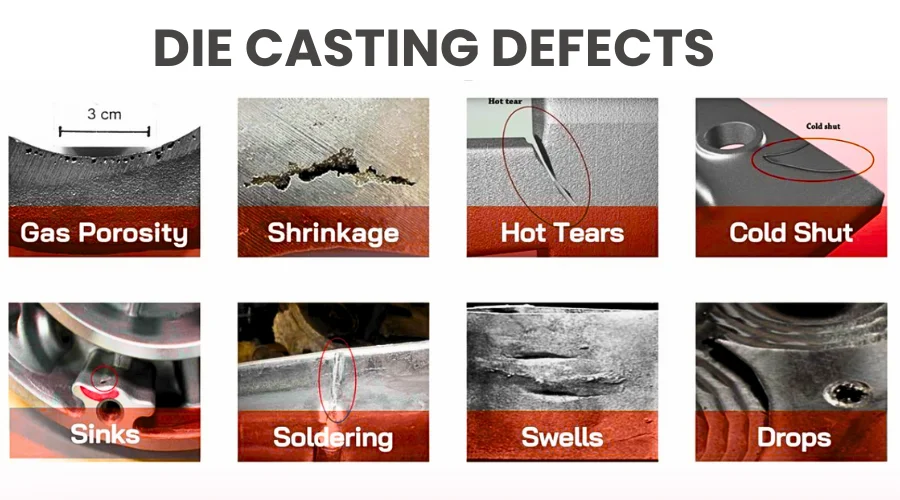

Defects of die casting arise during the die casting process that can affect the quality and performance of the product.

Here are several common defects:

- Flow marks

- Pattern

- Reticulated hairy fins (cracks)

- Cold separation

- Imprints

- Oxide scale

- Brushing and cracking

- Shrinkage Cavities

- Slag Inclusions and Inclusions

- Porosity and slag retention

- Oxides

- Thermal cracking

Die casting is a multi-functional process used for manufacturing complex and precise metal parts.

It is not only an efficient production technology, but also very economical and efficient in the long run.

Therefore, industries such as aerospace, automobiles, and electronics, which have a high demand for metal parts, all choose die-casting.

However, like any other manufacturing process, die casting also faces some challenges.

One of the main challenges is the existence of defects in the castings.

However, key components (such as those of automobiles and aircraft, etc.) must have no major defects.

Otherwise, it may even lead to catastrophic malfunctions.

Flow marks

This refers to the appearance of streaks or non-directional lines on the surface of the casting that are consistent with the flow direction of the metal.

The reasons for this are low mold temperature, poor sprue design, and low material temperature.

Pattern

Irregular sag linear patterns on the surface of the casting may be due to improper gating system design or uneven mold preheating.

Reticulated hairy fins (cracks)

This defect appears with the increase in the number of die castings and may be related to insufficient mold preheating.

Cold separation

Smooth depressions in the surface of the casting, usually due to low pouring temperatures or improper sprue placement.

Imprints

Traces or step marks on the surface of the casting in contact with the mold cavity, which may be due to ejection wear or unreasonable mold design.

Oxide scale

Oxides appear on the surface of the casting, which may be related to improper surface treatment of the mold or uneven paint spraying.

Brushing and cracking

These defects usually occur on the surface of the casting and may be due to the rough surface or poor venting of the mold.

Shrinkage Cavities

These defects usually occur in thick-walled areas of the casting and due to the shrinkage of the molten metal during the solidification process.

Slag Inclusions and Inclusions

These defects can be caused by impurities in the raw material or residues in the mold.

Porosity and slag retention

These defects can be related to improper control of alloy composition, pouring temperature, or mold temperature.

Oxides

In the high-pressure die casting process, oxide inclusions can occur due to the high speed of the molten metal impacting the mold surface.

Thermal cracking

This defect usually occurs during the cooling process and can be caused by an excessively large temperature gradient or too rapid cooling.

How to detect casting defects during the manufacturing process?

The detection of casting defects is crucial for ensuring the quality and performance of the products.

There are various methods in the die-casting industry for identifying and evaluating defects in the casting production process.

Visual inspection

The most obvious and direct method for identifying surface defects of castings (including pinholes or cold shuts) is visual inspection.

This helps to quickly identify defects in castings that may affect the appearance or structural integrity of the product.

Ultrasonic testing

Ultrasonic waves are used to detect internal defects, including pores and shrinkage cavities beneath the surface.

It is very effective for identifying internal defects that cannot be recognized by the naked eye.

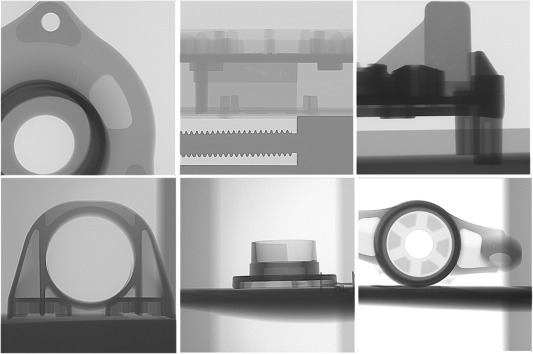

X-ray and gamma-ray inspection

X-ray and gamma-ray inspection is one of the effective methods for discovering internal defects in castings.

They can reveal pores caused by gas or shrinkage cavities, which may lead to a decrease in the strength of the casting.

Dye penetration testing

Dye penetration testing requires the application of dye on the surface of the casting.

Inspection under ultraviolet light can reveal surface defects of castings, such as cracks and fusion defects.

Solutions to Die Casting Defects

Mold Design

To reduce the occurrence of these defects, improvements can be made by optimizing the mold design, adjusting process parameters.

Such as pouring temperature, pressure, and time), improving the quality of raw materials, and improving the exhaust system.

There are many types of defects in the die casting process.

And understanding their causes and taking appropriate precautions is critical to improving product quality.

Improve the quality

Ensure uniform mold wall thickness and avoid areas that are too thin or too thick to reduce cratering and cracking problems caused by uneven cooling.

First of all, improve the manufacturing accuracy and surface quality of the mold.

And reduce the surface defects of the casting caused by the mold problem.

Secondly, the cooling channel should be reasonably arranged to ensure that the mold temperature is uniform and avoid casting defects caused by uneven mold temperature.

Die casting process control

First of all, control the pressure and speed parameters of the die casting machine.

To ensure that the molten metal can flow evenly when filling the cavity.

Avoiding defects such as porosity and shrinkage porosity.

Secondly, the pouring temperature of the molten metal and the mold temperature should be controlled to avoid problems.

Such as poor fluidity and mold sticking caused by low temperature.

Finally, the exhaust groove and paint should be reasonably arranged

To ensure that the gas can be discharged smoothly and avoid defects caused by gas retention.

Runner System Optimization

Optimize sprue, manifold, and gate systems to ensure smooth flow and fast filling of molten metal, reducing condensation and oxidation issues.

Mold Cooling System Improvement

Efficient design of vent grooves and vent holes ensures that there will be no defects.

Caused by the inability of gas to be discharged during the discharge of molten metal.

Material selection and treatment

In this regard, mold materials with high wear resistance, high thermal stability, and high strength are selected.

And appropriate heat treatment and surface strengthening treatment are carried out to improve the life and performance of the mold.

Intelligent Manufacturing & Data Analysis

Use CAD/CAM/CAE technology for mold design and process optimization, predict potential problems and optimize design solutions.

At the same time, the use of intelligent manufacturing technologies.

Such as the Internet of Things and real-time data analysis tools.

Continuously monitor the mold status and process parameters, and make timely adjustments to reduce defects.

Haichen Precautions of defects in die casting

Reasonable design of casting structure

Ensure uniform wall thickness of castings and avoid excessive heat joints.

Control pouring temperature and speed

Reduce pouring temperature or pouring speed appropriately to reduce the shrinkage of molten metal.

Optimize the gate riser system

Set the appropriate risers and gates.

Control of melt composition

Reduce gas and oxide content in metals and improve flowability.