Metal pipe fittings different types:

- Elbows

- Tees

- Reducers

- Couplings

- Unions

- Caps and Plugs

- Flanges

- Adapters

- Bushings

- Nipples

Metal pipe fittings are components that connect and manipulate metal pipes in a system.

Common types include elbows, tees, reducers, couplings, unions, caps, plugs, and various types of flanges.

These fittings are used to change direction, join pipes of different sizes, terminate pipes, and create various connections in piping systems.

A pipe fitting is a piping component that connects multiple pipelines. It can regulate and alter the course of a fluid in a pipe system.

For example, a pipe fitting can connect a thick pipe with a narrow pipe, reducing the volume of water.

Another example may be combining the water flow of two pipes into one using a tee fitting.

There is a lot of variety when it comes to pipe fittings. Some are mere connectors, while some alter the water volume.

Fittings specifications and piping standards are important considerations in pipeline design.

Improper connections may result in leakage or damage to the piping system. It is also necessary to match the material of the connector to that of the pipe.

Components differ in their quality, size, material, and construction. In the following sections, let’s discuss the different types of pipe fittings.

Elbows types

Pipe elbow is a key parts in a piping system for to change the fluid flow direction.

It is used to connect two pipes with same or different nominal diameters, and to make the pipe turn to a certain direction of 45 degree or 90 degree.

Used to change the direction of a pipe run, typically by 90 or 45 degrees.

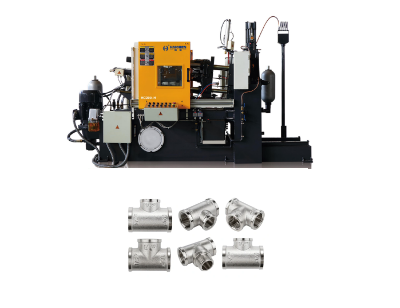

Tees types

Pipe fitting tees are available in a range of sizes and wall thicknesses to accommodate different piping systems.

The standard sizes for pipe fitting tees are typically measured in inches and range from 1/2″ to 48″ (DN15 to DN1200). The wall thicknesses can vary and are specified using various schedules.

Connect three pipes, with two at a right angle and one at a right angle to the other two.

Reducers types

A pipe reducer is a component used in the pipelines to reduce its size from large to small bore in accordance to the inner diameter.

The length of the reduction here is equal to an average of the smaller and larger pipe diameters. Here, the reducer can be used as a diffuser or a nozzle.

The reducer helps in meeting the existing piping of varied sizes or hydraulic flow of the piping systems.

Connect pipes of different diameters, reducing the flow rate from a larger to a smaller diameter.

Couplings types

Pipe couplings that connect pipes using a socket-welded joint are called socket-welded pipe couplings. This connection method involves inserting a steel pipe into a socket hole and welding it in place.

This connection method does not require complex threading or welding operations, making installation convenient and ensuring reliable sealing.

It features a compact structure, strong pressure resistance, and excellent sealing performance, and is commonly used in high-pressure and high-temperature environments.

They are widely applied in fields such as water supply and drainage, and municipal engineering.

Depending on the number of sockets, socket weld pipe couplings can be classified into single-socket pipe couplings and fullsocket pipe couplings.

Join two pipes of the same diameter, often used to repair or extend pipe runs.

Unions types

Facilitate the connection and disconnection of pipes, allowing for easier maintenance or repair.

A pipe union is a type of detachable pipe fitting connection consisting of two end joints and a locking nut in the middle, enabling quick assembly and disassembly without rotating the pipe body.

Depending on the connection method, pipe unions are mainly divided into two categories: socket weld unions and threaded unions.

These two types differ significantly in terms of structural design, installation method, sealing performance, and applicable scenarios.

Caps and Plugs types

Terminate pipes, either with or without threading, to seal them.

Pipe End Caps are a particular kind of fitting that are mostly utilized to cover a pipe end.

This prevents the entry of impurities such as water, dampness, dust, and others.

Additionally, it aids in avoiding material damage. Devices called pipe end caps aid in protecting the pipe ends.

They come in a variety of forms and sizes and are constructed from a variety of materials. End cap pipe fittings typically have a tear tab or strip to make removal simple.

They assist in lowering pressure dips and maintaining the cleanliness of a pipe’s inside in addition to safeguarding the end.

Flanges types

Provide a method for connecting pipes, valves, and other components using bolts and clamps, creating a tight seal.

Pipe flanges are one of the most used connection types for pipes.

These connections consist of three different parts: the pipe flange, a gasket, and bolting.

They are used for various industrial applications, pressure classes, and media.

They can connect piping in a system, connect components such as valves, containers, vessels, and many more applications.

These connectors benefit from a straight-through connection without loss of flow or pressure.

This article explores the most common pipe flange variants, their uses, and their most commonly used applications.

Adapters types

Adapters are piping components that attach different kinds of pipes.

For example, an adapter could contain a compression fitting at one end and a threaded fitting at the other.

Pipe adapters are made with both male and female connectors.

Adapters feature a wide range of opening shapes.

Threaded adapters are easy to install. You can connect pipes by twisting them together.

Compression adapters close tightly around the pipe to secure the joints.

For additional security, you may choose a barbed adapter.

It has barbs that secure to the pipe openings. Several other types of specialized adapters are available in the market.

Brass adapter joints resist oxidation and rusting, making them ideal for irrigation. Stainless steel adapters can bear high-pressure gas flow.

Copper and PVC adapters are suited for plumbing due to their corrosion resistance, heat conductivity, and pricing.

Bushings types

Connect pipes of different diameters, typically used to reduce the size of a larger pipe to a smaller one.

Sometimes, you may need to connect pipes that have different connectors.

This can often happen when revamping old pipe networks.

Bushing joints can connect pipes of different types, such as male-to-female or threaded-to-welded.

They can attach pipes of different sizes and openings. They can have internal or external threading.

Common materials for bush connectors are plastic, steel, brass, and bronze.

They are excellent for general use, chemical industry, plumbing, and oil pipelines.

Nipples types

Nipple fittings are male-threaded at both ends.

They can connect two female-threaded pipes.

They are often used in plumbing due to their efficient nut-and-bolt construction.

Plumbers can easily work them using a wrench.

A close nipple has little to no unthreaded space between the openings. Conversely, barrel nipples have a long length of unthreaded space between the openings.

A welding nipple has an unthreaded portion that can attach to a pipe opening.

Nipple joints are useful components in plumbing, oil, gas, and petrochemical industries.

Short, threaded pipes used for connecting fittings or other components.

Different types of metal pipe fittings application scenarios

- Petrochemical industry

- Shipbuilding

- Architecture and Municipal Engineering

- Energy and electricity

Petrochemical industry

Flanges and butt-weld elbows: Connect the reactor to the distillation tower and withstand high temperature and high pressure.

Reducer tee: Separates crude oil from refined products, and the material is mostly stainless steel or alloy steel.

Shipbuilding

Flange connection system: Used for fuel and cooling water pipelines, it is required to be resistant to salt spray corrosion (316L stainless steel).

Expansion compensator: Offsets the stress caused by thermal expansion and contraction to prevent pipeline deformation.

Architecture and Municipal Engineering

Threaded joints and mechanical clamping accessories: Quick installation of fire sprinkler systems, suitable for complex layouts.

Galvanized steel pipe elbows: Building drainage systems, balancing strength and rust prevention.

Energy and electricity

Alloy steel tee: Steam pipeline for supercritical units, with a temperature resistance of over 600℃.

Copper tube expansion joint fittings: Refrigerant transportation in refrigeration systems, ensuring sealing and heat conduction efficiency.

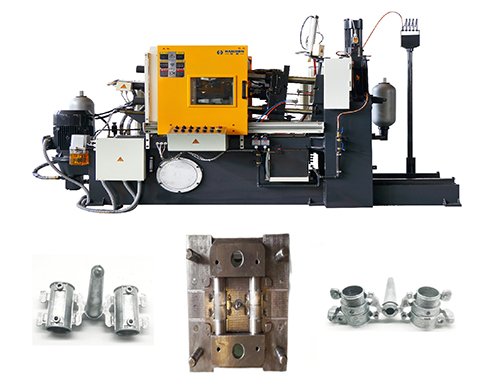

The manufacturing method of metal pipe fittings

- Die-cast method

- Aluminum alloy die-casting

Die-cast method

Fast-fitting with a special fastening tool (die-casting tool) without the need for high technical skills.

It requires a certain amount of space to operate, but does not require heating equipment, and is suitable for environments with flammable materials.

Insert the stainless steel pipe into the die-casting joint, and use a special fastening tool to die-cast the joint.

To reduce the diameter from the center to the end of the insertion part to realize the connection between the pipe and the joint.

Aluminum alloy die-casting:

Such as 40 diameter aluminum alloy round pipe joints cross cross, Y-shaped tee, etc., these joints are widely used in agricultural irrigation water pipes and other fields.

Type B die-cast zinc-aluminum alloy fittings: including straight and 90 degree elbow fittings, suitable for metal or non-metallic liquid sealing conduits.

These types of die-cast metal pipe joints have their own characteristics and advantages in different application scenarios.

Such as corrosion resistance, high strength, good sealing, etc., and are suitable for various industrial and construction fields.

Metal Pipe Fittings production

- Hydraulic cold forming process

- Seamless steel pipe production technology

- Cold working technology

Hydraulic cold forming process

Special metal pipe fittings usually adopt the international advanced hydraulic cold forming process, which can ensure that the pipe fittings maintain high precision and high quality in the manufacturing process.

Seamless steel pipe production technology

The manufacturing process of seamless steel pipe includes a variety of methods such as bolt rolling production, continuous rolling production, three-roller rolling production and extruded pipe production.

These processes are suitable for the production of steel pipes with different diameters and wall thicknesses.

Such as bolt rolling production is suitable for structural steel pipes with a diameter of more than 250mm.

While continuous rolling production is suitable for steel pipes with a diameter of less than 168mm.

Cold working technology

Cold working technology is used to strengthen metals and alloys to improve corrosion resistance and quality.

For example, stainless steel materials are becoming mainstream in the oil and gas and medical markets due to their corrosion resistance, formability, and cost-effectiveness.

Titanium tubing offers unique strength, density, and corrosion resistance for use in harsh environments such as aircraft hydraulics, medical implants, subsea equipment, and chemical plants.

Fabrication of special shapes and sizes

Fabrication of specialty tubing also includes the ability to customize special shapes and sizes.

For example, spiral boiler tubes form a rifle-like spiral pattern on the tube through a specially shaped mold to provide a more efficient heat exchange surface.

Fin heat exchanger tubes improve thermal efficiency by creating an extended surface on the surface of the base tube.

Haichen Metal Pipe Fittings Machine

Different types of die-cast metal pipe joints have their own characteristics and advantages in different application scenarios, such as corrosion resistance, high strength, good sealing, etc.

And are suitable for various industrial and construction fields.