Zinc alloys different types mainly include Zn-Mg alloy, Zn-Cu alloy, Zn-Ni alloy, Zn-Al alloy and so on.

Zin alloy is one of the most used elements. When combined with other elements, such as aluminum, zinc metal makes a zinc alloy.

There are many types of zinc alloys. Zamak and ZA series are the mainstream in the industry. The former focuses on casting performance, while the latter emphasizes strength. The casting and deformation processes determine the application scenarios. Aluminum, copper, and lead are the core alloying elements. The actual selection should be based on performance requirements and process conditions.

There are many types of zinc alloys, which can be divided into many types according to different alloy elements and uses. The following are some common types of zinc alloys

- Based on Alloy Metal

- Based on the Processing Method

- What are the characteristics of zinc alloy?

- What Are the Chemical Properties of Zinc Alloy?

Based on Alloy Metal

- Zn-Mg alloy

- Zn-Cu alloy

- Zn-Ni alloy

- Zn-Al alloy

- Zn-Cu-Al alloy

- Zn-based biodegradable alloy

Zn-Mg alloy

This alloy often uses in applications that require higher strength and corrosion resistance.

For example, 7075 alloy is an alloy containing 5.6% zinc, 2.5% magnesium, 1.6% copper and 0.25% chromium, which is widely used in the aerospace field.

Zn-Cu alloy

This alloy has good mechanical properties and corrosion resistance.

And is often uses in the electronics industry and automobile manufacturing.

For example, some studies mentioned Zn-Cu alloys containing different proportions of copper and zinc.

Zn-Ni alloy

It often uses in electroplating processes to improve the corrosion resistance and mechanical properties of the coating.

For example, Zn-Ni alloy coatings are widely used for anti-corrosion treatment of steel surfaces.

Zn-Al alloy

This alloy widely uses in the machining industry due to its low density and good mechanical properties.

For example, AA7005 and AA7020 are two common aluminum-zinc ternary alloys that excel in welding fatigue performance.

Zn-Cu-Al alloy

This alloy combines the advantages of copper and aluminum, has good conductivity and corrosion resistance.

And it is suitable for aerospace, vehicle equipment and other fields.

Zn-based biodegradable alloy

This alloy mainly uses in medical devices, such as stent materials. Studies have shown that zinc-based alloys have good biocompatibility and strength.

Moreover, it has a potential choice for degradable stent materials.

Based on the Processing Method

Die casting and related processing methods classify zinc alloys into various types. We have listed five common alloys.

- Die cast alloy

- Continuous casting

- Hot chamber die cast alloy

- Electroplating alloy

- Forging zinc alloy

Die cast alloy

These alloys contain a complete family – ZAMAK! Its main components are aluminum, zinc, magnesium, and copper. Sometimes, you can also find zinc alloys containing aluminum in this category.

Continuous casting

This zinc alloy contains more aluminum than ZAMAK. The higher the content of aluminum, the higher the strength of the alloy.

Hot chamber die cast alloy

These alloys contain aluminum, copper, and zinc. These metals have high strength and better ductility.

Electroplating alloy

When nickel and zinc meet, they can prevent corrosion. You can treat it through electroplating. And provide corrosion resistance for steel components.

Forging zinc alloy

ZAMAK is the preferred choice for forging zinc alloy derivatives. It provides users with excellent mechanical strength and durability.

What are the characteristics of zinc alloy?

- Excellent castability

- Good strength

- Corrosion resistance

- Enhanced surface finish

- High thermal conductivity and electrical conductivity

- Good casting and connection performance

- Recyclability

Zinc alloys have various characteristics, making them ideal for various applications. Here are some key characteristics of zinc alloys:

Excellent castability

Zinc alloy has excellent fluidity and low melting point, making it highly malleable. They can be easily cast into complex shapes and thin-walled structures, allowing for the production of complex parts with high dimensional accuracy.

Good strength

Zinc alloy has good strength and hardness, comparable to some other non-ferrous metals. They can withstand moderate loads and provide structural integrity for various applications.

Corrosion resistance

Zinc alloy has excellent corrosion resistance, especially compared to other base metals. The protective oxide layer formed on the surface of the alloy helps prevent further oxidation and further enhances its corrosion resistance.

Enhanced surface finish

Zinc alloy can achieve a smooth and aesthetically pleasing surface finish. They are commonly used in decorative applications that require high-quality appearance. Zinc alloys are easy to coat with various metals, thereby further enhancing their surface properties.

High thermal conductivity and electrical conductivity

Zinc alloy has good thermal conductivity and electrical conductivity, which can achieve efficient heat dissipation and electrical conductivity in applications that require such performance.

Good casting and connection performance

Zinc alloy has a low melting point and can achieve economically efficient casting processes, such as die-casting and investment casting. In addition, zinc alloys also have good bonding properties and are easy to weld, brazing, and brazing.

Recyclability

Zinc alloys have high recyclability, and the energy consumption during the recycling process is much lower than that of primary production. This makes zinc alloy an environmentally friendly choice.

Haichen Practice Different Types of Zinc Alloyscase

Optimizing Die-Casting Production Solutions for Different Types of Zinc Alloys

Haichen understands the unique requirements of different zinc alloy types for die-casting processes and can help customers achieve optimal production results through equipment and technical adjustments.

Customer Project Background

A hardware manufacturer needed to simultaneously produce high-gloss decorative parts (using Zamak 3) and high-strength structural components (using ZA-8) efficiently on the same production line.

Process Analysis Addressing Material Differences

Haichen engineers identified distinct melting characteristics, shrinkage rates, and required injection curves for each zinc alloy type. Zamak 3 demands rapid, stable filling for flawless surfaces, while ZA-8 requires higher final injection pressure and more effective venting.

Haichen Die-Casting Machine Adaptation Solution

Haisen configured a high-performance cold-chamber die-casting machine for the client, activating its multi-set process parameter storage function. For Zamak 3, the transition point from low to high speed was optimized to achieve laminar filling. For ZA-8, higher boost pressure and faster pressure build-up time were set.

Production Benefits Achieved

By instantly retrieving preset parameters, the customer rapidly switches between producing two distinct zinc alloy parts. This approach significantly enhances equipment utilization and production flexibility while meeting the quality requirements for each material.

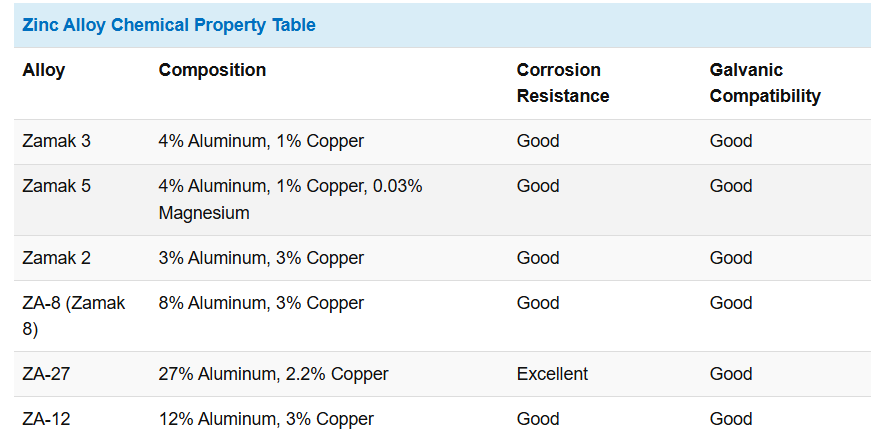

What Are the Chemical Properties of Zinc Alloy?

Zinc alloy chemical composition

| Alloy | Composition | Corrosion Resistance | Galvanic Compatibility |

| Zamak 3 | 4% Aluminum, 1% Copper | Good | Good |

| Zamak 5 | 4% Aluminum, 1% Copper, 0.03% Magnesium | Good | Good |

| Zamak 2 | 3% Aluminum, 3% Copper | Good | Good |

| ZA-8 (Zamak 8) | 8% Aluminum, 3% Copper | Good | Good |

| ZA-27 | 27% Aluminum, 2.2% Copper | Excellent | Good |

| ZA-12 | 12% Aluminum, 3% Copper | Good | Good |

Above all, zinc alloys widely use in industry and medical fields due to their diverse composition and excellent properties. Different types of zinc alloys show their unique performance advantages according to their specific composition and use.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine.They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts. When you have any demand, feel free to contact us.