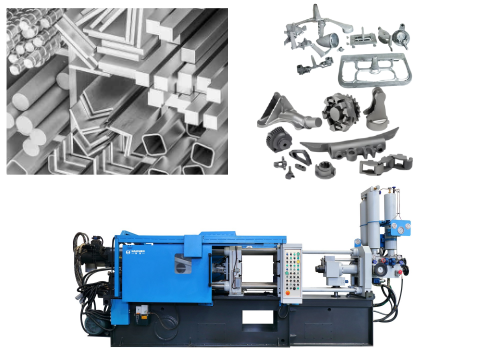

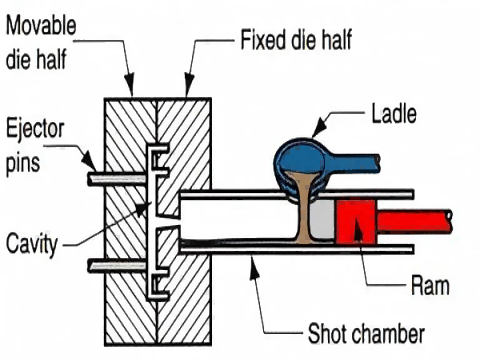

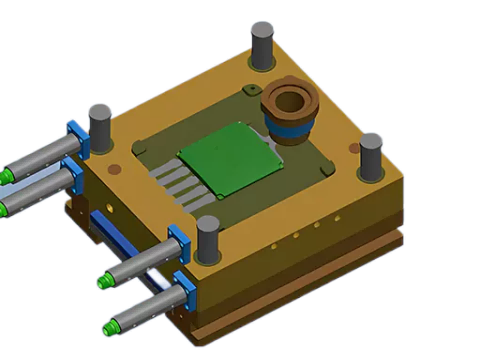

Die casting is a high-pressure manufacturing process that involves injecting molten metal into steel molds. While efficient, the process is susceptible to several failure modes that impact tool life, product quality, and operational costs.

Die casting involves injecting molten metal into a mold cavity under immense pressure. This method is particularly suitable for the rapid manufacture of large metal parts, which require minimal post-production machining. Therefore, it is widely adopted by medical mold companies and medical plastics manufacturers.

Die casting is a common production process in the metal casting industry. It is primarily divided into two types, in addition to other process design variations.

Common Failure Modes of Die Casting

Below are the primary failure modes, their causes, and implications:

- Thermal Fatigue Cracking (Heat Checking)

- Soldering (Metal Adhesion)

- Erosion

- Corrosion

- Gross Fracture

- Preventive Measures

Thermal Fatigue Cracking (Heat Checking)

- Description: A network of fine surface cracks forms due to cyclic thermal stresses from repeated heating (molten metal injection) and cooling (solidification and die cooling) .

- Causes:

- Rapid temperature fluctuations (e.g., brass die casting involves melt temperatures up to 970°C) .

- Localized plastic strain accumulation in the die surface .

- Impact: Reduces surface finish quality, alters part dimensions, and leads to premature die failure.

Soldering (Metal Adhesion)

- Description: Molten metal adheres to the die surface, leaving residuals that impair part ejection and damage the tool .

- Causes:

- Chemical interaction between the die material (e.g., H13 steel) and the casting alloy (e.g., aluminum, zinc, or brass) .

- Insufficient die lubrication or improper surface treatments .

- Impact: Increases downtime for die cleaning and accelerates wear.

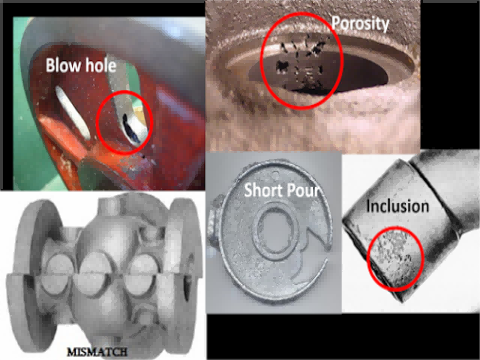

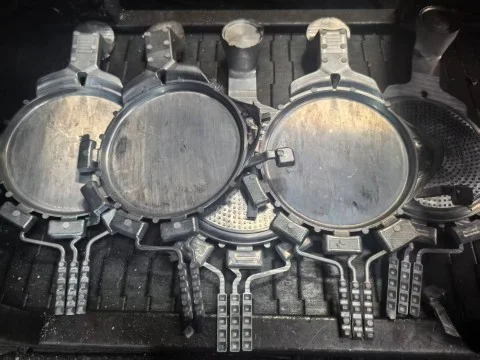

Erosion

- Description: Material loss on the die surface due to high-velocity molten metal flow, especially at the injection point .

- Causes:

- Abrasion from solid particles in the melt (e.g., impurities in aluminum alloys).

- High injection velocities (1–10 m/s in brass die casting) .

- Impact: Alters cavity geometry, leading to dimensional inaccuracies in cast parts.

Corrosion

- Description: Chemical dissolution of the die material into the molten metal .

- Causes:

- High-temperature exposure to reactive alloys (e.g., brass with lead content).

- Oxidation of crack surfaces during thermal cycling .

- Impact: Accelerates crack propagation and surface degradation.

Gross Fracture

- Description: Sudden, catastrophic failure of the die due to mechanical overloading or thermal shock 10.

- Causes:

- Excessive clamping forces or misaligned dies.

- Thermal gradients during rapid cooling (e.g., water spray cooling) .

- Impact: Total tool failure, requiring costly replacements.

Preventive Measures

- Surface Treatments:

- Proprietary coatings like MetaLLife or TherMaLLife reduce stress risers and improve die longevity .

- Material Selection:

- Use hot-work tool steels (e.g., AISI H13, QRO 90 Supreme) with high temper resistance .

- Process Optimization:

- Implement vacuum-assisted casting to minimize porosity and thermal stress .

- Design Adjustments:

- Avoid sharp corners in die designs to reduce stress concentrations .

Remedial measures for failure modes of die casting

To address die casting mold failures, targeted strategies must be implemented based on specific failure modes. Below is a detailed analysis of key failure modes and their solutions:

- Thermal Fatigue Cracking (Heat Checking)

- Mechanical Fatigue & Fracture

- Erosion & Dissolution

- Dimensional Failure & Distortion

- Preventive Maintenance & Management

Thermal Fatigue Cracking (Heat Checking)

- Causes: Cyclic heating and cooling generate alternating thermal stresses, leading to microcrack propagation on the mold surface.

- Remedial Measures:

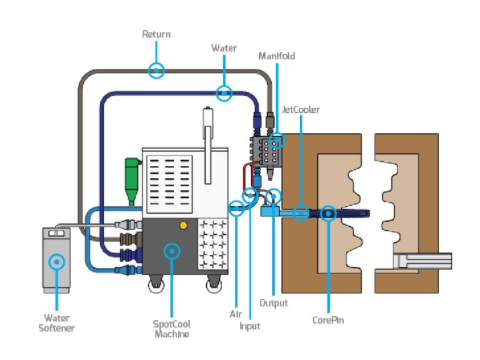

- Mold Preheating & Temperature Control: Preheat molds thoroughly before production and maintain stable operating temperatures (e.g., ~288°C for aluminum alloy molds).

- Surface Treatments:

- Apply shot peening to enhance surface fatigue resistance.

- Use nitriding, PVD coatings, or specialized coatings (e.g., TooLLife) to improve wear resistance and thermal shock resistance.

- Design Optimization:

- Increase fillet radii (e.g., >1mm for aluminum alloys) to reduce stress concentration.

- Use replaceable inserts in high-wear areas (e.g., gate zones) to allow localized repairs.

Mechanical Fatigue & Fracture

- Causes: Untempered rehardened layers post-EDM (electrical discharge machining), material defects, or operational errors.

- Remedial Measures:

- Post-Processing: Grind EDM-treated surfaces to remove rehardened layers and prevent crack initiation.

- Material Selection & Heat Treatment: Use premium hot-work steels (e.g., H13) with optimized heat treatment (e.g., double tempering) to enhance toughness.

- Flow Design: Avoid abrupt changes in molten metal flow direction; optimize runner geometry to minimize turbulence.

Erosion & Dissolution

- Causes: Chemical corrosion or mechanical wear from high-temperature molten metal.

- Remedial Measures:

- Advanced Materials: Use copper-based alloys or nickel superalloy inserts in critical areas for corrosion resistance.

- Process Optimization: Control metal temperature (e.g., ≤660°C for aluminum) and injection speed to reduce mold impact.

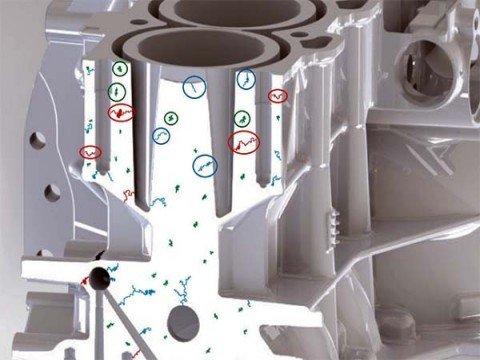

Dimensional Failure & Distortion

- Causes: Poor design or cumulative plastic deformation during prolonged use.

- Remedial Measures:

- Design for Manufacturability (DFM): Simulate mold behavior to optimize wall thickness and cooling channel design.

- CFD Simulation: Use computational fluid dynamics to optimize gate geometry and minimize defects like cold shuts.

Preventive Maintenance & Management

- Maintenance:

- Regularly inspect for cracks and repair via welding (ensure material compatibility).

- Promptly address surface damage to extend mold life.

- Process Standardization:

- Establish validated process parameters (e.g., injection speed, cooling time) through DOE (design of experiments).

Effective die casting mold failure prevention requires a holistic approach spanning design, material selection, manufacturing, and process control. By integrating preheating protocols, structural optimization, surface treatments, and advanced simulation tools, mold lifespan can be significantly extended while reducing downtime and production costs.

By the end

The dominant failure modes in die casting—thermal fatigue, soldering, erosion, corrosion, and gross fracture—arise from thermal, mechanical, and chemical stresses. Addressing these requires a combination of advanced materials, surface engineering, and process controls. For example, thermal fatigue in brass dies can be mitigated using lead-free alloys and optimized cooling systems.

Please email or call us to let Haichen provide you with more detailed die-casting technology details.