Die cast mold metals are specialized tool steels and alloys engineered to withstand extreme thermal cycling, abrasion, and high-pressure molten metal exposure.

Metals need to meet the stringent requirements of high temperature, high pressure, wear resistance and thermal fatigue resistance.

Die cast mold metals–Aluminum Alloys

- Lightweight

- Corrosion resistance

- High thermal conductivity

- Ease of processing

- Common alloy types

- Applications

Lightweight

The density is only 2.7 g/cm³, which is 1/3 of steel, and is widely used in fields that require weight reduction (such as automobiles, aerospace).

Corrosion resistance

The surface is prone to the formation of an alumina protective layer, which is suitable for parts exposed to moisture or corrosive environments.

High thermal conductivity

Excellent heat dissipation performance, commonly used in engine components and electronic equipment radiators.

Ease of processing

Complex structures can be formed by cold chamber die casting with low subsequent processing costs.

Common alloy types

ADC12 (A383): High silicon content (9.6%-12%), good flowability, suitable for thin-walled parts (e.g. automotive dashboards).

A380: Balanced strength and casting performance for engine mounts and pump bodies.

AA 413: Outstanding heat resistance for building components in high-temperature environments.

Applications

Automotive industry: engine blocks, transmission housings, suspension systems (accounting for more than 40% of automotive lightweight materials).

Consumer electronics: laptop cases, mobile phone frames (taking advantage of their electromagnetic shielding properties).

Industrial machinery: hydraulic valve bodies, pump casings (depending on their high strength and fatigue resistance).

High melting point (about 660°C), cold chamber die casting machine is required, and the equipment cost is higher than that of zinc alloy.

Creep may occur after long-term exposure to high temperatures, which requires alloy design optimization (e.g. addition of copper and magnesium).

Die cast mold metals–Zinc Alloys

- Applications

- Limitations

High fluidity: Low melting point (380-420°C), suitable for hot chamber die casting, can form ultra-thin walls (below 0.5mm) and fine textures.

Excellent surface quality: the surface finish of the casting is up to Ra 0.8-1.6μm, and it can be straight.

Zamak 3: North American mainstream alloy, containing 4% aluminum, 0.1<% copper, balanced strength and ductility (tensile strength 283 MPa).

Zamak 5: Added 1% copper, hardness increase (Brinell 91), used in European car door locks and gears.

ZA-8: 8.4% aluminum, the only high-strength zinc alloy that can be die-cast in a hot chamber to replace brass parts.

Applications

Hardware: door handles, locks (chrome or nickel plated surface).

Electronic devices: connector housings, heat sinks (RF shielding performance is better than plastic).

Precision instruments: watch movements, gears, medical devices (relying on their high dimensional accuracy).

Limitations

High density (6.6 g/cm³), not suitable for very lightweight scenarios.

The ductility of copper-containing alloys decreases after long-term aging, and impurities (lead, cadmium< 0.005%) need to be strictly controlled.

Die cast mold metals–Magnesium Alloys

- Core features

- Common alloy models

- Applications

Core features

Ultra-lightweight: 1.8 g/cm³ density, 33% lighter than aluminum, higher specific strength (strength/density ratio) than steel.

High shock absorption: The damping coefficient is 30 times that of aluminum alloy, which is used to reduce mechanical vibration.

Fast solidification: 50% shorter die casting cycle than aluminum alloy, longer mold life (no iron erosion).

Common alloy models

AZ91D: 9% aluminum, 1% zinc, the best comprehensive performance, accounting for 70% of the market (automobile steering wheel skeleton, drone fuselage).

AM60B: Outstanding ductility (12% elongation) for automotive seat frames and dashboard brackets.

AE42: High temperature resistance (continuous operation at 180°C), replacing aluminum alloy engine cylinder head.

Applications

Aerospace : satellite mounts, helicopter gearboxes (significant weight reduction).

3C products: laptop cases, camera bodies (stronger than plastic and recyclable).

New energy vehicles: battery tray, motor housing (combined with lightweight and electromagnetic shielding requirements).

Limitations

Inert gas protection (e.g. CO₂) is required for melting, and the equipment is complex and costly.

Poor corrosion resistance and requires surface treatment (micro-arc oxidation or coating).

Other Alloys

Copper Alloys: High conductivity (58-100% IACS), used in electrical connectors and ship components, but expensive and difficult to die cast (melting point 1083°C).

Iron Alloys: Excellent wear resistance, used in heavy machinery gears, but high density (7.8 g/cm³) and fast die loss.

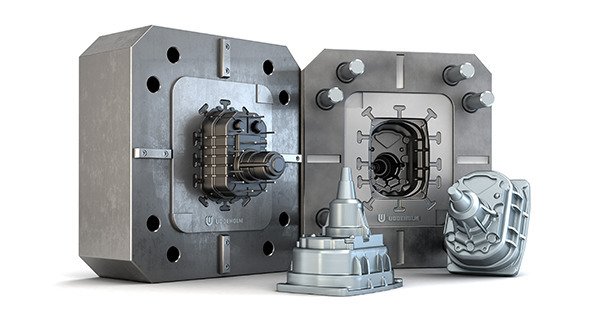

Tool steels and hot work die steels-die cast mold metals

- H13 steel (4Cr5MoSiV1)

- SKD61

- 3Cr2W8V

- DIEVAR Steel

- 8407 steel

- Copper-based alloys

H13 steel (4Cr5MoSiV1)

Characteristics

High toughness, excellent heat fatigue resistance, working temperature ≤ 600°C, suitable for repeated thermal cycling environment.

The surface hardness can reach 750HV through nitriding treatment, which prolongs the service life.

Application

The mainstream choice of aluminum alloy and magnesium alloy die-casting molds, such as automobile engine blocks, gearbox housings, etc.

Advantages

Cost-effective, domestic H13 is widely used in small and medium-sized batch production.

Imported H13 (such as SKD61) has higher purity and longer life span by more than 30%.

SKD61 (Japanese standard, corresponding to H13)

Characteristics

Similar to H13 composition, but the production process is better, the impurity content is low, and the toughness and polishing effect are better.

Application

High-precision, high-volume production scenarios, such as consumer electronics shells, complex structural parts.

Cost

The price is about 2 times that of the national standard H13, which is suitable for high-end needs.

3Cr2W8V

Characteristics

High tungsten content (8%), high temperature resistance up to 650°C, but the toughness is only half of H13, prone to thermal fatigue cracks.

Application

Cold chamber die casting molds, copper alloy die casting (such as copper radiators), some zinc alloy molds.

Limitations

It is gradually replaced by H13, but it still has applications in superalloy die casting.

DIEVAR Steel (Modified H13)

Characteristics

Improved red hardness and ductility, enhanced crack resistance, suitable for very large molds or continuous production.

Application

Integrated die-casting mold for new energy vehicles, such as Tesla Model Y rear bottom plate.

8407 steel

Characteristics

High purity, excellent resistance to hot cracks, and 50% longer life than ordinary H13.

Application

High-end aluminum alloy die-casting, such as aviation parts, precision instrument housings.

Copper-based alloys (e.g. CuCr, beryllium copper)

Characteristics

Excellent thermal conductivity (5 times that of steel), rapid heat dissipation reduces thermal stress, but high cost.

Application

Partial inserts are used in areas with high heat loads, such as gate sleeves or ejector pins for die-casting molds.

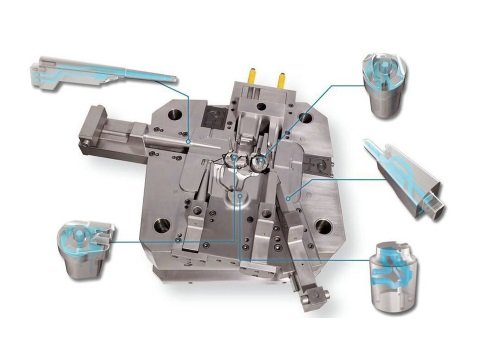

Types of die-casting molds

- Aluminum alloy die casting mold

- Zinc alloy die casting mold

- Magnesium alloy die casting mold

Aluminum alloy die casting mold

The temperature of the aluminum alloy melt is usually around 1202~1292℉.

The mold life of aluminum alloy die casting molds should be focused on whether mold sticking and early dry cracking of the mold cavity occur.

At present, General used aluminum alloy die casting mold steels included: 4Cr5MoSiV1 (H13), 4Cr5MoSiV (H11), 3Cr2W8V, and new steel grades Y10 and HM3.

Zinc alloy die casting mold

The melting point of zinc alloy is 752~806℉, and the surface temperature of the zinc alloy die-casting mold cavity will not exceed 400°C.

The materials generally used to manufacture zinc alloy die-casting molds are alloy structural steels 40Cr, 30CrMnSi, 40CrMo, etc., alloy mold steels 5CrNiMo, 5CrMnMo, 4Cr5MoSiV, 4Cr5MoSiV1, 3Cr2W8V, CrWMn, etc.

Magnesium alloy die casting mold

The melting point of magnesium alloy is 1202℉.

Die-casting has a good molding feature.

The tensile strength of magnesium alloy castings is equivalent to that of aluminum alloy castings, generally up to 250Mpa, up to more than 600Mpa.

The most commonly used is H13 steel or materials with similar properties.

After machining, the cavity part is quenched and annealed to make the hardness within the range of 46-48HRC.

Only the cavity part and special parts of the mold need to use H13 steel, and these parts generally account for 20-30% of the weight of the entire mold.

The other parts of the mold are made of low-carbon steel and medium-carbon steel.

For smaller die cast parts with relatively simple geometric switches, molds of standardized modules are often used.

Compared with aluminum alloy, magnesium alloy has lower hot melt, and its iron content is also very low. Therefore, the mold has a longer life.

Die cast mold Maintenance and use recommendations

Preheating & Cooling Control

The mold is preheated to 200-300°C (aluminum alloy) to reduce thermal shock.

The temperature difference of the cooling water is controlled within ±5°C to avoid local stress concentration.

Regular maintenance

The parting surface wear is checked every 5000 molds, and the microcracks are repaired by laser cladding.

Clean up carbon deposits in the exhaust groove to prevent air bubble defects caused by gas entrapment.

Through reasonable material selection and process optimization, the life of die-casting molds can be increased from 100,000 molds to more than 300,000 molds, significantly reducing production costs.