Casting alloys must meet the requirements of good fluidity, low shrinkage, strong resistance to hot cracking, good airtightness, wear resistance, and mechanical and physical properties required for the final product.

To ensure the performance and quality of castings, casting alloys must meet core process requirements such as fluidity, resistance to hot cracking, and shrinkage.

These characteristics directly determine their ability to fill the mold, resist defects, and solidify during the die-casting process.

Ultimately, the alloy’s comprehensive mechanical properties and corrosion resistance must meet the specific application standards of the end product.

What are the requirements for casting alloys

- Material Composition of casting alloys

- Mechanical Properties of casting alloys

- Surface and Dimensional Requirements

- Corrosion Resistance

- Heat Treatment

- Testing and Inspection

Material Composition of casting alloys

Chemical Composition:

The alloy must meet specific chemical composition requirements to ensure its properties. For example, steel and alloy castings for industrial use must conform to the chemical composition standards set by organizations like ASTM. The exact composition depends on the intended application.

Purity:

Impurities can significantly affect the quality of the casting. High-purity materials are essential to minimize defects and enhance the mechanical and corrosion-resistant properties.

Mechanical Properties of casting alloys

Strength and Ductility:

The alloy must possess the required tensile strength, yield strength, and elongation to meet the application’s demands. For instance, higher strength alloys are often used in structural applications but may require more complex heat treatment processes.

Fatigue Resistance:

This is crucial for components subjected to cyclic loading. The alloy’s fatigue resistance depends on factors like strength, ductility, surface finish, and residual stresses.

Casting Process

Flow and Fillability:

The alloy should have good fluidity to fill the mold cavities completely and avoid defects like porosity or incomplete filling. This is particularly important in die-casting processes.

Shrinkage and Expansion:

The alloy’s thermal expansion and contraction behavior during cooling must be controlled to prevent shrinkage cavities or cracks.

Surface and Dimensional Requirements

Surface Quality:

The casting surface should be free of defects such as adhering sand, scale, cracks, and hot tears. In some cases, surface treatments like machining or coating may be required to achieve the desired finish.

Dimensional Accuracy:

The alloy casting must meet the specified dimensional tolerances. For example, die-cast aluminum alloy products require good dimensional accuracy and stable size.

Corrosion Resistance

Environmental Compatibility:

The alloy must be resistant to corrosion in its intended environment. This includes resistance to oxidation, pitting, and stress corrosion cracking. For example, certain aluminum alloys are designed to have good corrosion resistance in marine or chemical environments.

Heat Treatment

Post-Casting Treatment:

Many alloy castings require heat treatment to achieve the desired mechanical properties. This process can improve strength, toughness, and overall performance. The specific heat treatment depends on the alloy and application.

Testing and Inspection

Quality Control:

The alloy castings must undergo various tests and inspections to ensure they meet the required standards. These can include chemical analysis, mechanical testing, and non-destructive testing methods such as ultrasonic or radiographic inspection.

Process Assurance for Achieving Core Performance

The theoretical properties of cast alloys, such as good fluidity, low shrinkage tendency, and high strength, must ultimately be achieved through stable processes in the die-casting production process. This transformation process is highly dependent on the precision, repeatability, and intelligence level of the die-casting machine. Advanced die-casting equipment, through its precise control system, becomes crucial in ensuring that the alloy properties are reproduced in every part.

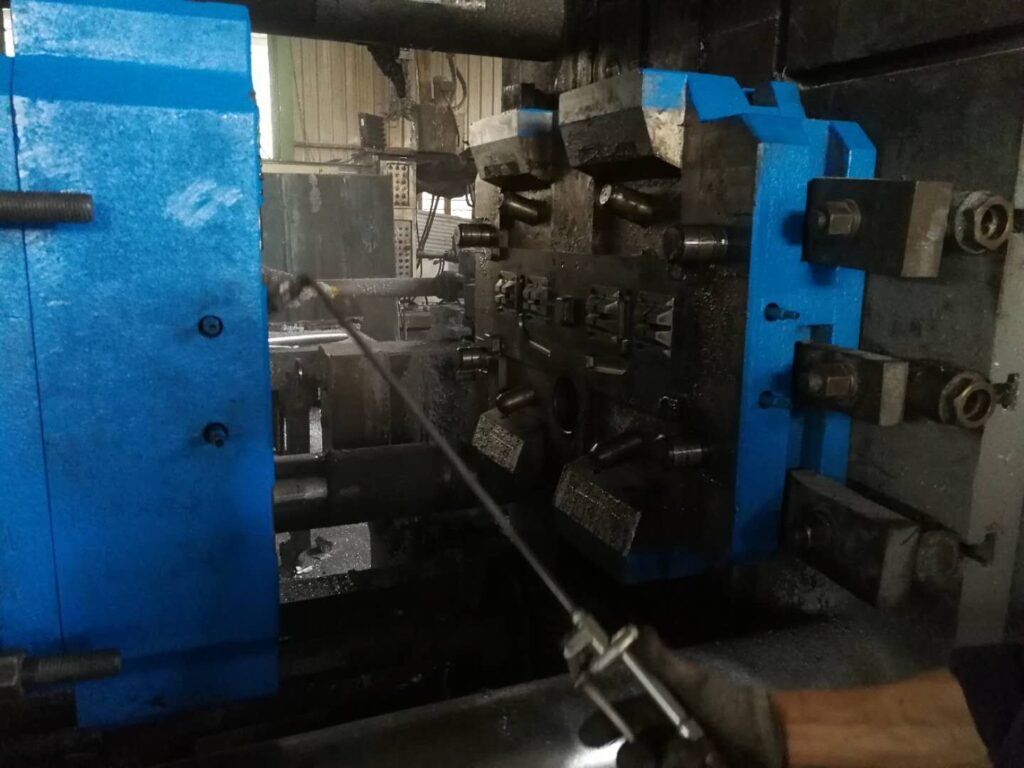

Taking the production of load-bearing structural components, such as aluminum alloy road studs, as an example, the material needs to possess high fluidity to fill complex structures and low thermal cracking tendency to ensure strength. The product specifications are: 15x15cm in size, 580g per piece, using a complex four-cavity, eight-slide mold, with the main mold core made of H13 steel, and a target life of 50,000 cycles.

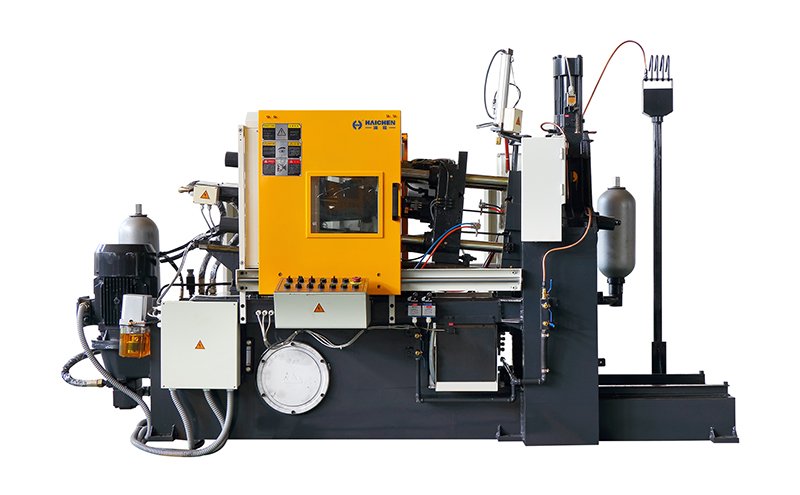

Die casting machine supplier: Haichen Machinery

Haichen Machinery is a supplier of die casting machines and other related equipment. We specialize in providing die casting production solutions for various materials, including aluminum, magnesium, zinc, and copper alloys. Our cold chamber and hot chamber die casting machines are used for manufacturing products such as automotive parts, LED lamp shells, radiators, and household appliance components.

A Systematic Engineering Process from Materials to Products

Meeting alloy requirements is just the beginning. Successfully mass-producing qualified products is a systematic engineering endeavor that requires deep integration of equipment capabilities, mold design, and process parameters. Excellent die-casting machine manufacturers can provide professional support throughout this process.

Haichen’s Engineering Practices in Supporting Customers to Realize Alloy Potential:

In-depth Process Development for Special Applications

For challenging products like the aforementioned aluminum alloy road studs (heavy, multi-cavity, multi-slider), Haichen’s process team provides in-depth involvement. This includes:

- Mold Review: During the mold design phase, suggestions are made from the perspectives of filling, venting, cooling, and demolding to ensure that the mold design matches the alloy properties and machine capabilities.

- Customized Process Setup: Beyond setting injection curves, we precisely adjust the core-pulling sequence and force of the eight slides, as well as the cooling water’s on/off time, ensuring a smooth and stable production process and preventing scratches or cracks in the alloy due to poor demolding at high temperatures.

- Process Validation and Optimization: We assist clients with First Article Inspection (FAI), inspecting internal quality using X-rays, confirming dimensions with a coordinate measuring machine, and fine-tuning the process based on the results to ensure the alloy’s mechanical properties are fully translated into product performance.

Selecting the right alloy for die casting is a systematic engineering decision-making process. It requires achieving the best balance between excellent casting processability, mechanical and physical properties that meet service conditions, controllable production costs, and compatibility with existing die casting equipment, molds, and post-processing techniques.