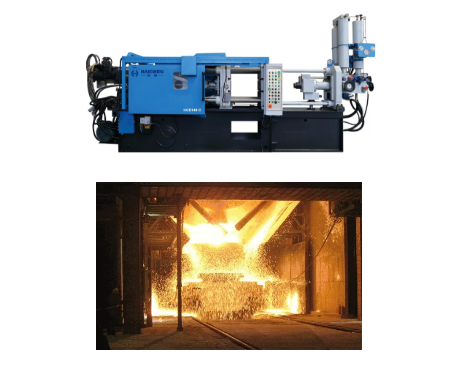

Safety practices during metal casting is crucial to prevent injuries and ensure a safe working environment. Metal casting involves several hazards, including high temperatures, molten metal, fumes, and heavy equipment.The die-casting process presents numerous health and safety hazards requiring particular vigilance. For all factories engaged in metal die-casting, foundry safety must be prioritised.

The most obvious safety hazard in die casting is burns. Employees must handle molten metal at extremely high temperatures. Contact with materials or equipment can cause severe injury.

However, burns are not the sole health and safety risk in die casting. Safety protocols must also address dust inhalation, heat stress, and eye protection.

Safety practices during metal casting

By following these safety practices, metal die casting operations can significantly reduce the risk of accidents and ensure a safer working environment for all personnel involved.

- Personal Protective Equipment (PPE)

- Proper Ventilation

- Safe Handling of Molten Metal

- Furnace and Equipment Safety

- Fire Safety

- Training and Procedures

- Workspace Organization

- Emergency Preparedness

- Environmental Controls

Personal Protective Equipment (PPE)

- Heat-resistant clothing: Wear flame-resistant clothing, such as leather aprons, gloves, and sleeves, to protect against burns.

- Face and eye protection: Use safety goggles, face shields, or helmets with shaded lenses to protect against splashes, sparks, and intense light.

- Footwear: Wear steel-toed, heat-resistant boots to protect feet from molten metal spills and heavy objects.

- Respiratory protection: Use respirators or masks to avoid inhaling fumes, dust, or particulates, especially when working with materials like silica or certain alloys.

Proper Ventilation

- Ensure adequate ventilation in the workspace to remove harmful fumes, gases, and dust generated during melting and pouring.

- Use local exhaust ventilation (LEV) systems or fume extraction equipment near furnaces and pouring areas.

Safe Handling of Molten Metal

- Always use appropriate tools (e.g., ladles, tongs, and crucibles) designed for handling molten metal.

- Ensure tools are dry and preheated to prevent steam explosions when they come into contact with molten metal.

- Avoid overfilling ladles or crucibles to prevent spills.

- Pour molten metal slowly and steadily to minimize splashing.

Furnace and Equipment Safety

- Regularly inspect furnaces, crucibles, and other equipment for cracks, wear, or damage.

- Follow proper startup and shutdown procedures for furnaces.

- Keep flammable materials away from furnaces and molten metal.

- Use temperature controls and monitors to prevent overheating.

Fire Safety

- Keep fire extinguishers rated for Class D fires (metal fires) readily available.

- Avoid using water to extinguish metal fires, as it can cause explosions.

- Store flammable materials in designated areas away from casting operations.

Training and Procedures

- Ensure all workers are trained in safe casting practices, emergency procedures, and the proper use of PPE.

- Follow established standard operating procedures (SOPs) for each step of the casting process.

- Conduct regular safety drills and reviews of safety protocols.

Workspace Organization

- Keep the work area clean and free of clutter to prevent tripping hazards.

- Mark safe zones and pathways for moving molten metal.

- Store raw materials and finished products in designated areas.

Emergency Preparedness

- Have first aid kits and emergency eyewash stations readily accessible.

- Establish clear emergency response plans for burns, fires, and spills.

- Train workers on how to respond to accidents involving molten metal.

Environmental Controls

- Dispose of waste materials, such as used sand or slag, in accordance with environmental regulations.

- Recycle materials where possible to reduce waste and environmental impact.

By adhering to these safety practices, workers can minimize risks and ensure a safer metal casting process. Regular safety audits and continuous improvement of safety protocols are also essential.

Haichen die casting machine supplier

Haichen is a well-known manufacturer and supplier of die casting machines, based in China. They specialize in producing high-quality cold chamber die casting machines, hot chamber die casting machines, and other related equipment for industries such as automotive, electronics, and home appliances. If there is any demand, welcome to consult us.