Die casting machine safety precautions are a set of essential rules and measures to protect operators and ensure smooth production.

This article outlines key safety steps, explains why each is important, and shows how proper procedures prevent accidents. We will also discuss machine features that support a safe workplace.

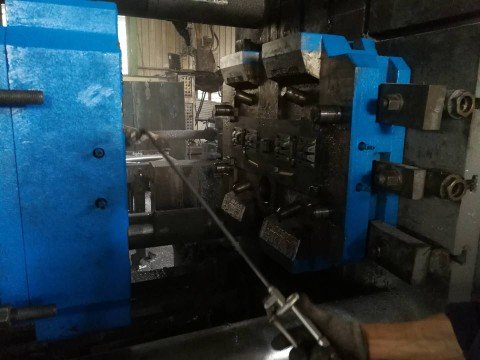

Die casting is a manufacturing process that involves forcing molten metal under high pressure into a mold cavity. Operating a die casting machine comes with significant safety risks, so strict these precautions are essential to protect workers and equipment.

- Essential Personal Protective Equipment

- Safe Machine Operation Procedures

- Handling Molten Metal and Housekeeping

- Equipment Inspection of die casting machine safety precautions

Essential Personal Protective Equipment

All personnel must wear proper safety gear near the machine.

- Protection from Heat and Splash

- Hand and Foot Safety

Protection from Heat and Splash

Always wear a full face shield alongside safety glasses. Use flame-resistant clothing to cover your arms and legs. This gear shields you from hot metal splashes and burns. Therefore, never operate a machine without it.

Hand and Foot Safety

Wear heavy-duty, heat-resistant gloves for handling hot items. Similarly, steel-toe boots protect your feet from heavy falling parts. Proper footwear prevents serious injuries in the work area.

Safe Machine Operation Procedures

Following correct procedures is vital for daily safety.

- Using Safety Guards and Interlocks

- Lockout/Tagout for Maintenance

Using Safety Guards and Interlocks

Keep all safety guards in place and ensure interlocks function. These devices prevent the machine from cycling if a door is open. For instance, a broken interlock can lead to a serious crush hazard.

Lockout/Tagout for Maintenance

Before any service work, follow the lockout/tagout (LOTO) rule. This means isolating all energy sources and using a personal lock. After that, you can safely perform maintenance without unexpected machine movement.

Handling Molten Metal and Housekeeping

A clean and alert environment prevents many common hazards.

- Safe Metal Transfer Practices

- Maintaining a Clean Workspace

Safe Metal Transfer Practices

Check that all tools and ladles are completely dry. Moisture causes violent steam explosions in molten metal. Pour carefully and avoid overfilling containers to minimize splash risks.

Maintaining a Clean Workspace

Clean spills of oil, water, or metal scraps immediately. Clear walkways ensure safe movement and quick escape. Good housekeeping is a fundamental die casting machine safety precaution.

Equipment Inspection of die casting machine safety precautions

- Regular Maintenance: Inspect the machine regularly for wear and tear, leaks, or malfunctions.

- Check Safety Devices: Ensure all guards, interlocks, and emergency stop buttons are functional.

- Inspect Mold Alignment: Verify proper alignment and condition of the die mold to prevent damage or accidents.

Worker Protection

- Personal Protective Equipment (PPE): First, wear heat-resistant gloves, face shields, and safety goggles. Second, use protective aprons and steel-toed boots.

- Training: Train workers on machine operation, safety procedures, and emergency response.

Machine Operation

- Pre-Operation Checklist: Confirm that the work area is clear of unauthorized personnel and ensure the material feed system is free of obstructions.

- Safe Practices: Never reach into the die cavity while the machine is operating. And do not bypass or disable safety mechanisms.

Emergency Preparedness

- Fire Safety: Have fire extinguishers rated for metal fires (Class D) nearby. And keep flammable materials away from the die-casting area.

- Emergency Shutoff: Know the location of emergency shutoff controls and ensure they are easily accessible.

- First Aid: Provide first aid kits and train staff in handling burns or injuries.

Environmental Controls

- Fume Extraction: Install exhaust systems to remove hazardous fumes from the workspace.

- Spill Management: Have spill containment and cleanup procedures in place for molten metal.

Ergonomics and Workspace Safety

- Clear Pathways: Keep floors clean and free of obstructions to prevent slips and falls.

- Ergonomic Tools: Use tools and equipment designed to reduce physical strain on workers.

Electrical Safety of die casting machine safety precautions

- Proper Wiring: Ensure all electrical connections are secure and insulated.

- Lockout/Tagout Procedures: Use lockout/tagout systems during maintenance or repairs to prevent accidental startup.

HAICHEN’s Engineering for a Safer Workplace

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.designs machines with integrated safety to support these precautions.

- Robust Construction and Guarding

- Advanced Control and Alert Systems

- Our Commitment as Your Partner

Robust Construction and Guarding

Our machines feature heavy-duty frames and fixed safety guards. This strong build reduces vibration and contains moving parts. In other words, the machine itself acts as a primary safety barrier.

Advanced Control and Alert Systems

We install multiple emergency stop buttons and clear alarm systems. These features give operators immediate control and clear warnings. For example, our visual and audio alerts signal issues before they become hazards.

Our Commitment as Your Partner

As a leading manufacturer, HAICHEN’s advantage is building reliability and safety into every machine. We provide the stable, well-guarded equipment that forms the foundation of your safety program. Our design philosophy directly supports your key die casting machine safety precautions.

Following die casting machine safety precautions protects your team and your productivity. Always use proper PPE, follow operating rules, and maintain a clean shop. Choose equipment from partners like HAICHEN, who prioritize built-in safety. In conclusion, combining vigilant habits with reliable machinery creates the safest and most efficient foundry environment.