A connection rod to break the block includes excessive mechanical stress, insufficient lubrication, fatigue and wear and others.

The causes of connecting rod fracture can attribute to a variety of factors. Including mechanical stress, insufficient lubrication, fatigue, material defects, external factors, and engine overspeed.

In order to prevent connecting rod fracture, the engine lubrication system should check regularly. The connecting rod bolts should tighten the engine overspeed should avoid. And worn or damaged parts should replace in time. In addition, the selection of high-quality connecting rod materials and processing technology is also an important measure to reduce the risk of fracture.

There are many reasons for connecting rod fracture, mainly related to mechanical stress inside the engine, insufficient lubrication, fatigue and external factors. The following is a detailed analysis of the possible causes of connecting rod fracture:

- Excessive mechanical stress

- Fatigue and wear

- Excessive overspeeding

- Hydrolock

- External factors

- Other mechanical failures

Excessive mechanical stress

- Material Fatigue

- Excessive Mechanical Stress

- Insufficient Lubrication or Oil Circuit Failure

- Gudgeon pin failure

The connecting rod is subjected to huge compressive and tensile forces during engine operation. Especially when the piston moves up and down, the stress is subjected to increases cubically with the increase in engine speed.

This high stress can cause fatigue fracture of the connecting rod, especially when the material strength is insufficient or the design is flawed.

Material Fatigue

Connecting rods are repeatedly stretched and compressed during each operating cycle. Thousands of cycles per minute can cause microcracks within the material, which eventually expand into fractures. Aging, low-quality materials, or surface defects can accelerate fatigue failure.

Excessive Mechanical Stress

Overrevving or operating under high loads (such as towing or racing) can cause peak pressures in the cylinder to surge. Causing tensile, compressive, and bending stresses on the connecting rod to momentarily exceed their design limits, leading to fracture.

Insufficient Lubrication or Oil Circuit Failure

A loss of oil film can cause overheating and increased friction in the connecting rod big-end bearing. Leading to localized temperature increases, decreased material strength, and even bearing seizure (hydrolock), which can push the connecting rod into the cylinder block.

Gudgeon pin failure

When the gudgeon pin breaks, the connecting rod loses its connection to the piston. The impact force acts directly on the big end of the connecting rod, which can easily throw the connecting rod out of the cylinder block.

Fatigue and wear

- Material Fatigue

- Wear/lack of oil

- Insufficient Structural Strength

After long-term use, the connecting rod will gradually crack due to fatigue. These cracks usually start from stress concentration areas of the connecting rod, such as near the lubrication channel or processing defects. In addition, material fatigue of the connecting rod can also cause it to break under high loads.

Material Fatigue

- Specific Manifestations and Mechanisms:

Connecting rods are subjected to alternating compression and tension loads during each operating cycle. Over time, this cumulative effect leads to the initiation and propagation of microcracks, ultimately leading to fracture at stress concentrations. - Common Causes:

Extended use, low-quality or mismatched materials, insufficient fatigue strength design, and inadequate protection against stress concentrations.

Wear/lack of oil

- Specific Symptoms and Mechanisms:

Insufficient bearing oil film causes direct contact between the connecting rod big end and the crankshaft journal, resulting in friction and localized overheating, accelerating material softening and crack formation. - Common Causes:

Insufficient oil, contaminated oil, lubrication system leaks, or improper maintenance.

Insufficient Structural Strength

- Specific Manifestations and Mechanisms: Insufficient fatigue strength and stiffness of the big-end bolt or connecting rod body leads to bending or torsional instability under high loads.

- Common Causes: Improper design, material defects (inclusions, segregation), and residual stresses from machining.

Excessive overspeeding

- Overspeed (Overrevving)

- Fatigue

- Piston Pin Failure

- Insufficient lubrication or oil film failure

Overspeeding the engine can significantly increase the stress on the connecting rod, making it more susceptible to fracture.

For example, when the engine speed exceeds the design limit, the mechanical load on the connecting rod increases sharply, causing fracture.

Overspeed (Overrevving)

- When the engine speed exceeds the design limit, the instantaneous impact force of the piston at top dead center increases dramatically. The tensile and compressive stresses on the connecting rod can instantly exceed the material’s limits, causing fracture near the piston pin and impacting the cylinder block.

- Overspeed often occurs when manually shifting too early, releasing the clutch too quickly, or accelerating at high speed in a low gear.

Fatigue

- The connecting rod undergoes alternating tension and compression during each operating cycle. Long-term cyclical loads can cause microcracks within the material, eventually leading to fracture over accumulated mileage.

- Low oil levels, poor oil quality, or high-temperature operation can accelerate the fatigue process.

Piston Pin Failure

Worn or broken piston pins can cause the connecting rod to lose its connection with the piston. The impact force is applied directly to the big end of the connecting rod, which can easily break and penetrate the cylinder block.

Insufficient lubrication or oil film failure

- A broken oil film allows the big end bearing to come into direct metal contact, generating high temperatures, friction, and localized stress concentrations.

- It can lead to connecting rod fracture.

Poor filtration, insufficient oil supply from the oil pump or use of unqualified engine oil are common causes.

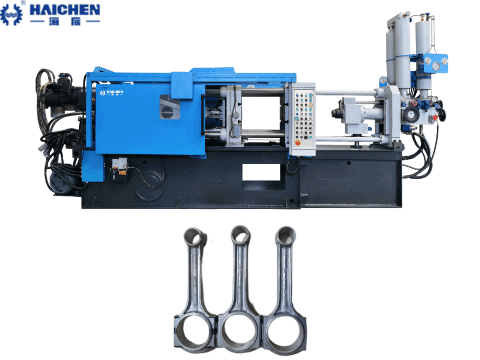

Haichen’s Approach to Ensuring Connecting Rod Reliability

We prevent such failures through manufacturing processes and provide assistance when customers encounter issues.

- Diagnosing Chronic Failures case study

- Haichen’s Design Philosophy and Support

Diagnosing Chronic Failures case study

Like one of our Haichen customers who experienced two connecting rod fractures within six months on an older machine, each causing significant production downtime. Haichen engineers were invited to investigate.

We determined the root cause lay not in the connecting rods themselves, but in severely worn crosshead guide plates. This misalignment caused the connecting rods to bend slightly with each cycle, triggering fatigue fractures.

We replaced the guide plates and damaged connecting rods with Haichen genuine parts and performed a full frame calibration. Following this repair, the machine has operated without fault for over two years.

Haichen’s Design Philosophy and Support

This case exemplifies our focus on the entire system. Haichen die-casting machines utilise high-quality forged alloy steel connecting rods designed with safety margins.

Crucially, our service extends beyond replacing damaged components to identifying root causes and preventing recurrence. For our customers, this translates to maximised uptime and reduced long-term risk.

Hydrolock

- What is Liquid Lock?

- Extreme Loads Generated

- Damage Path to the Cylinder Block After a Connecting Rod Breaks

If coolant or other liquids enter the cylinder, the connecting rod will not work properly due to hydrolock. In this case, the connecting rod may break due to mechanical obstruction.

What is Liquid Lock?

- When incompressible liquids such as water, coolant, or fuel enter the combustion chamber, the piston is unable to compress them during its upward stroke.

- Since the volume of the liquid remains essentially unchanged, the piston is forced to stop within a very short stroke, causing the engine’s internal rotational inertia to be “stuck” instantly.

Extreme Loads Generated

- Compression Force: When the engine is running at high speed or at high rpm (near or at maximum RPM), the upward kinetic energy of the piston is enormous, generating instantaneous compression pressures of up to several thousand kilograms.

- Impact Force: This impact force first acts on the piston pin and connecting rod, causing the connecting rod to bend or break under pressure.

Damage Path to the Cylinder Block After a Connecting Rod Breaks

- A broken connecting rod, still driven by the engine’s rotational inertia, often penetrates the piston and connecting rod housing, directly impacting and puncturing the cylinder wall, creating a significant hole and ultimately rendering the engine useless.

- Shock can also cause chain reactions such as crankshaft breakage, cylinder head cracking, and bearing damage.

External factors

- Improper bolt/nut assembly

- Material defects

External factors, such as loose connecting rod bolts, incorrect installation or damage, can also cause connecting rod fracture. For example, loose or broken connecting rod bolts can directly cause connecting rod failure.

Improper bolt/nut assembly

- Symptoms: Undertorqued, overtightened, or worn bolts.

- Explanation:Loose or overtightened bolts can cause slight misalignment between the connecting rod cap and connecting rod. Cyclic loads can lead to fatigue failure of the bolts, which can cause the connecting rod to lose its restraint and wear out.

Material defects

- Defects in the connecting rod material, such as improper processing, rough surface or internal stress concentration, can also cause it to break.

- For example, some connecting rods may produce microcracks during the manufacturing process due to processing problems. These cracks will expand under long-term use and eventually lead to fracture.

Other mechanical failures

Other common connecting rod failures include piston pin sticking, piston ring wear, or excessive clearance between the piston and cylinder wall. It may cause the connecting rod to be subjected to additional mechanical stress and thus break.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. At the same time, we produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.