A boosting hand wheel in die casting is a personnel control mechanism that let users apply extra force, albeit manually, to the injection unit, control the application of force during the injection process of the mold, which is quite useful for achieving very precise part quality.

This is especially beneficial for maintaining a high-performance and consistent part quality.

Within the die casting sector, there are numerous parts and constituents which are critical in the smooth operation execution of the casting process.

One of the components of this machine is the boosting hand wheel which is aimed at add extra control and extra precision during the casting cycle.

In the succeeding parts of this article, we will discuss the importance of boosting hand wheel in die casting operations.

Explanation of Boosting Hand Wheel

A boosting hand wheel is a controller that can be found on die casting machines. It can enable the operators to inject additional effort to the injection unit manually. This is especially beneficial for areas that need a high level accuracy and uniformity of the components.

Function of Boosting Hand Wheel

- Focused Adjustment Precision Control

- Precision Consistency

- Flexibility

Focused Adjustment Precision Control

The alllocated functions of the boosting hand wheel are to control operations of the injection accurately. Focused control of injection can ensure that the operators can fill the mold with the required amount of metal, thus enabling flawless castings.

Precision Consistency

Maintaining the same level of part for quality for a long period of time is also achievable with the boosting hand wheel. The risk of highly undesired outcomes such as porosity. Incomplete filling of the mold or surface finish problems can be greatly reduced.

Flexibility

Because of the boosting hand wheel, the operators are able to properly control the casting. It helps them respond to changes in the mold configuration and the attributes of the material being casted.

Benefits of Using Boosting Hand Wheel

- Improved Part Quality

- Reduced Defects

- Enhanced Operator Control

Improved Part Quality

Boosting hand wheels aids by ensuring constant control of the injection process. This ensures constant monitoring of casting production to achieve precision in high quality castings and sustaining surface smoothness throughout tightening surface finishes.

Reduced Defects

Higher control of the injection force manually handled subsequently reduces the chances of defects which in turn increases the quality of the achieved parts and simultaneously reduces the level of scrap produced.

Enhanced Operator Control

Operators are equipped with the hand boost wheels which enhances the ease of control over the whole procedure of casting. The ease of control granted enables real time changes to be computed while achieving stable production rate over time.

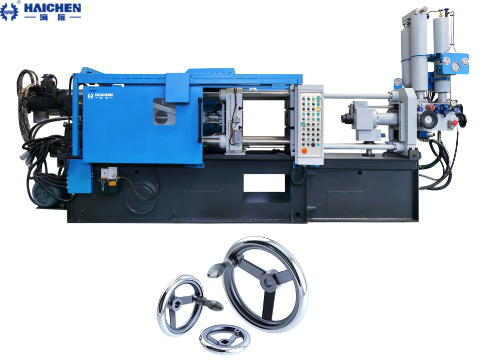

HAICHEN’S Innovation in Boosting Systems

HAICHEN as a front runner in providing solutions for die casting integrates the boosting hand wheels with:

- AI-Driven Optimization: The need for pressure by a certain mold geometry triggers pressure need predictions by machine learning algorithms.

- Eco-Efficiency: During a period when the system is idle, certain energy saving modes lower the rate of hydraulic consumption while making adjustments.

- Customization: For better adaptation, hand wheels are made to suit the machine size, for example, 160 – 250 mm diameters and also the ergonomics of the operator.

The boosting hand wheel permits precise control over the injection process thereby assisting in ensuring part quality, achieving high production efficiency while minimizing defects.