The crankcase is a key component in an engine and usually consists of an upper and lower crankcase,we use crankcase making machine to produce.

Crankcase is like a protective container in the middle of the engine. It holds critical engine parts like the crankshaft and lubricates them with oil to reduce friction and wear. The crankcase also helps prevent oil leaks. The crankcase is an integral part of the engine that essentially holds all engine components together.

Oil sump. The oil pan is an important part of the crankcase of a wet sump engine. Oil is stored here and is used to lubricate the various parts of the engine.

Crankshaft. The crankshaft is the heart of the engine and it works with the engine pistons to keep the wheels turning.

Camshaft. The camshaft helps the engine ‘breathe’ by controlling the engine’s exhaust valves, which allow exhaust gases to escape.

It provides a support platform for the engine’s crankshaft, while storing lubricating oil and enclosing the superstructure.

Through its design, the crankcase converts the force transmitted by the connecting rods into rotational torque, which drives the other components of the engine to work together.

What machines are used to produce crank case?

The production of crankcase casings involves mainly die-casting machines and a variety of machines and processes.

The following equipment and techniques may be used for the production of crankcase housings:

- Aluminium alloy die-casting machine production

- Robotic grinding system

- Specialised machine tools

- Multi-axis drilling machine

Aluminium alloy die-casting machine production

A cold chamber die casting machine is used to die cast a molten aluminium alloy solution to form the main body of the crankcase housing.

Robotic grinding system

Used to clean up the burrs produced during the casting process to improve production efficiency and product quality.

Specialised machine tools

Specialised machine tools designed for crankcase hole system machining, used to improve machining accuracy and productivity.

Multi-axis drilling machine

Used for crankcase side threaded bottom hole processing, improve drilling position accuracy and processing efficiency.

Together, these machines and technologies support the efficient, high-quality production of crankcase shells.

Crank case die-casting machine production process

The process of crankcase shell die-casting machine production mainly includes the following steps:

- Mould design and manufacture

- Metal melting

- Pouring system design

- Die casting moulding

- Cooling and curing

- Mould opening and removal

- Cleaning and post-treatment

- Quality Inspection

- Automation optimisation

Mould design and manufacture

Design and manufacture of moulds for crankcase shell die-casting, to ensure that the moulds can meet the production requirements, including precision and strength.

Metal melting

Melting the aluminium alloy and other materials, controlling the melting temperature and chemical composition to ensure the quality of the crankcase shell.

Pouring system design

Design reasonable pouring system, including straight sprue, cross sprue, riser, etc., in order to ensure that the metal liquid can fill the crankcase shell mould smoothly.

Die casting moulding

Molten metal is injected into the crankcase shell mould through high pressure for rapid cooling and curing to form the crankcase shell.

Cooling and curing

Cooling and curing is carried out in the mould to ensure the structural integrity and dimensional accuracy of the crankcase shell.

Mould opening and removal

Upon completion of cooling in the mould, you can take out the crankcase shell products after mould fully open.

Cleaning and post-treatment

Clean the crankcase shell, remove surface defects and burrs, and carry out necessary heat treatment and machining.

Quality Inspection

Quality inspection of the finished crankcase shell to ensure that it meets the technical requirements.

Automation optimisation

Improve production efficiency and crankcase shell qualification rate through automation equipment and process optimisation.

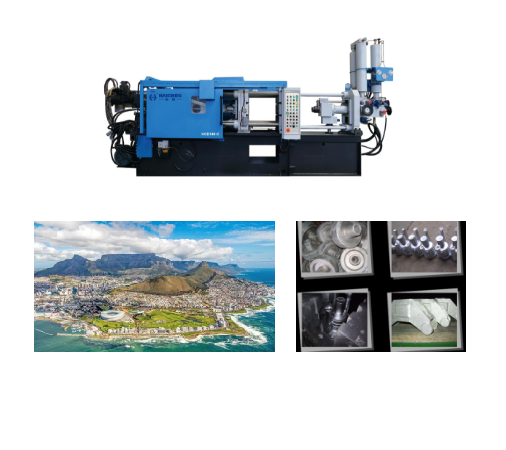

Haichen high-quality crankcase making machine

We offer high-quality crankcase housing die-casting machines that meet a wide range of technical requirements and production needs.

For example, Haichen uses a high-pressure die casting process to manufacture crankcase housings made of aluminium alloy.

This ensures that the castings are strong, wear-resistant and corrosion-resistant.

In addition, Haichen optimises the mould structure and die casting process parameters to improve the qualification rate and production efficiency of crankcase castings.

At the same time, for the crankcase body internal defects (such as air holes and shrinkage holes) of the problem.

Haichen has taken a number of design improvement measures to ensure stable quality improvement of crankcase production machines.