What is a High Pressure Die Casting Machine: It injects molten metal under high pressure into molds to produce precise, complex metal parts.

High Pressure Die Casting (HPDC) machines specialize in producing high-quality metal parts by injecting molten metal into a mold at high speed and under high pressure.

This process widely uses in the manufacturing of automotive parts, aerospace components, and various consumer products because it can produce complex shapes with high precision and excellent surface finish.

This article will provide an overview of what a high pressure die casting machine is, its key components, and how it works.

Key Components of a High Pressure Die Casting Machine

- Injection System

- Die or Mold

- Clamping Unit

- Ejection System

- Control System

Injection System

The injection system is responsible for melting the metal and injecting it into the mold. It includes the melting furnace, injection cylinder, and plunger. The metal is heated to its melting point and then forced into the mold cavity at high speed.

Die or Mold

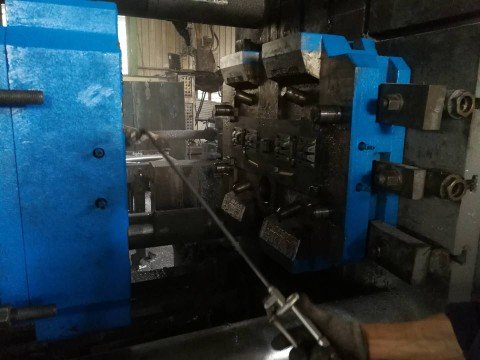

The die, also known as the mold, is the part of the machine that gives the molten metal its shape. We typically make it from high-quality steel and design it to withstand the high pressures and temperatures involved in the casting process. The mold consists of two halves that come together to form the cavity.

Clamping Unit

The clamping unit holds the mold halves together during the injection process. It must provide sufficient force to prevent the mold from opening due to the high pressure of the injected metal. The clamping unit also ensures precise alignment of the mold halves to maintain dimensional accuracy.

Ejection System

The ejection system is responsible for removing the solidified casting from the mold. It typically includes ejector pins or plates that push the finished part out of the mold cavity once the metal has cooled and solidified.

Control System

The control system manages the entire casting process, from melting the metal to ejecting the finished part. It ensures precise control over injection speed, pressure, cooling time, and other parameters. Modern HPDC machines often use advanced computer controls and automation to optimize efficiency and quality.

How a High Pressure Die Casting Machine Works

- Preparation: We prepare the mold by applying a release agent to facilitate the removal of the casting. Then, we close and clamp the mold halves together.

- Injection: The molten metal is injected into the mold cavity at high speed and under high pressure. The metal fills the cavity quickly, ensuring a complete and detailed filling.

- Cooling: The metal is allowed to cool and solidify within the mold. Cooling channels in the mold help to control the cooling rate and ensure uniform solidification.

- Ejection: Once the metal has solidified, the mold halves are separated, and the ejection system removes the casting from the mold.

- Post-Processing: The casting may undergo additional processes such as trimming, machining, or surface treatment to achieve the final product specifications.

Benefits of High Pressure Die Casting

- High Precision: HPDC machines can produce parts with very tight tolerances and complex geometries.

- High Production Rates: The process is highly automated and can produce large volumes of parts quickly.

- Excellent Surface Finish: The high pressure and speed ensure a smooth surface finish, reducing the need for secondary operations.

- Lightweight Parts: HPDC allows for the production of lightweight parts with high strength, making it ideal for automotive and aerospace applications.

Applications of High – Pressure Die Casting Machines

- Automotive Industry

- Aerospace Industry

- Consumer Electronics

Automotive Industry

The automotive industry widely uses HPDC machines to produce lightweight components such as engine blocks, transmission housings, and wheel hubs. The ability to create complex and lightweight parts helps improve fuel efficiency and overall vehicle performance.

Aerospace Industry

The aerospace industry benefits from the high strength – to – weight ratio of HPDC parts. Components such as aircraft structural parts and engine components are produced using this process, ensuring high – quality and reliable performance.

Consumer Electronics

The consumer electronics industry relies on HPDC machines to produce lightweight and durable parts. Components such as laptop casings, smartphone frames, and other electronic enclosures are commonly produced using this process.

HAICHEN Mold Case Study: 280X70 Aluminum Fry Pan Mold

This project used a HAICHEN 650-ton cold chamber die casting machine to make a large, thin-wall aluminum fry pan mold. It shows HAICHEN’s skill in making molds for complex thin-wall parts.

- Project Challenge

- HAICHEN Solution

Project Challenge

The product was an aluminum fry pan, 280mm in diameter and 70mm tall. The bottom wall was 4mm thick, and the side wall was 2.8mm thick. The main challenge was to make sure the molten aluminum could fill the whole thin, deep mold cavity. We also needed even wall thickness and a smooth surface.

HAICHEN Solution

HAICHEN provided a full service from mold design to process testing.

- Mold Design: We used a center gate and fan-shaped runner system. This made the aluminum flow smoothly from the pan bottom to the sides. We added several vents in the deep areas of the cavity to let air escape.

- Precision Machining: We used a 5-axis CNC machine to make the mold cavity. This gave a smooth surface and even wall thickness. The key parts fit together with an accuracy of ±0.015mm.

- Cooling System: We built separate cooling channels for the bottom and the sides of the mold. This let us control the cooling speed for different areas and reduce warping.

The mold worked successfully on the first try with the HAICHEN 650-ton machine. The cast part filled completely with no defects. The wall thickness variation was within ±0.1mm. The mold achieved a stable cycle time of 45 seconds, and the product yield rate was over 98.5%.

HAICHEN: Your Partner in High Pressure Die Casting Solutions

At HAICHEN, we specialize in manufacturing advanced high pressure die casting machines designed to meet the highest standards of precision and reliability. We engineer our machines to ensure consistent production quality and efficiency, making them ideal for a variety of manufacturing needs. Whether you are producing automotive parts, aerospace components, or other high-precision products, HAICHEN offers the tools and expertise to help you achieve your production goals.

Why Choose HAICHEN?

- Advanced Technology: Our die casting machines integrate Siemens PLC control systems. And ISO-certified components that maintain ≤0.1% defect rates in high-volume production.

- Custom Solutions: We offer tailored machine configurations to meet specific production needs, including mold size, material type, and production volume.

- Quality and Reliability: HAICHEN manufactures machines to aerospace-grade standards, delivering 99.2% operational reliability with ≤0.3% annual downtime across our installed base.

- Comprehensive Support: Our commitment to customer satisfaction includes comprehensive after-sales support, technical assistance, and maintenance services.

A high pressure die casting machine is a sophisticated piece of equipment that plays a crucial role in the production of high-quality metal parts. Its ability to produce complex shapes with high precision and excellent surface finish makes it an essential tool in modern manufacturing.