Aluminum cold chamber die casting is a specific type of die casting process used primarily for metals with high melting temperatures, such as aluminum.

Process of Aluminum cold chamber Die Casting

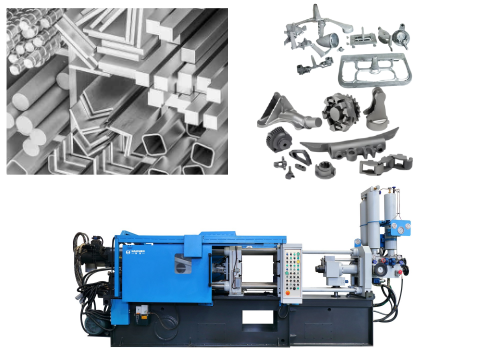

Aluminum die casting is a metal forming process in which molten aluminum is injected into a mold cavity under high pressure and allowed to cool and solidify to form a part.

Mold Preparation:

The mold (also called a die) is made from high-quality steel. It consists of two halves that can be opened and closed. It is precisely machined to form the desired shape of the final part.

The mold is coated with a release agent to prevent the molten aluminum from sticking to the surface.

Metal Preparation

Aluminum is melted in a separate furnace outside the machine. The melting temperature for aluminum typically ranges from 650°C to 700°C.

The molten aluminum is then transferred to a holding furnace or ladle, which is part of the machine.

Injection

The molten aluminum is ladled or poured into a shot sleeve (also called a cold chamber) in the machine. This chamber is not heated and is kept at a lower temperature compared to the molten metal.

A hydraulic plunger or piston then forces the molten aluminum from the shot sleeve into the mold cavity at high speed and under high pressure (typically around 1,500 to 20,000 psi).

Cooling and Solidification

Once the molten aluminum fills the mold cavity, it begins to cool and solidify. The cooling time depends on the thickness and complexity of the part.

The mold remains closed until the part has fully solidified.

Ejection and Trimming

After solidification, the mold is opened, and the part is ejected using ejector pins.

Any excess material, such as flash or runners, is trimmed away to obtain the final part.

Advantages of Aluminum Cold Chamber Die Casting

Suitability for High-Melting-Point Metals:

Aluminum has a relatively high melting temperature. And the cold chamber process is well-suited for metals like aluminum, zinc alloys, and magnesium that require high-temperature handling.

High Precision and Complexity:

The process allows for the production of parts with intricate designs, thin walls, and tight tolerances. The high injection pressure ensures that the molten metal fills even the most complex mold cavities.

Good Mechanical Properties:

The rapid cooling rate during solidification helps to refine the microstructure of the aluminum, resulting in parts with good mechanical properties. Such as high strength and hardness.

Lightweight Parts:

Aluminum is a lightweight material, making cold chamber die casting ideal for applications where weight reduction is important. Such as in the automotive and aerospace industries.

Aluminum Casting machine supplier: Haichen Machinery

Haichen Machinery is a Chinese company specializing in the manufacturing and supply of aluminum cold chamber die casting machines, hot chamber die casting machines and related equipment. We offer a range of die-casting solutions, including cold chamber die casting machines, which are commonly used for aluminum, magnesium, and other non-ferrous alloys.

Aluminum cold chamber die casting is a highly efficient and versatile manufacturing process that is particularly well-suited for producing high-quality, complex parts from high-melting-point metals like aluminum. Its ability to deliver precision, high production rates, and good mechanical properties makes it a popular choice across various industries, including automotive, aerospace, and electronics.