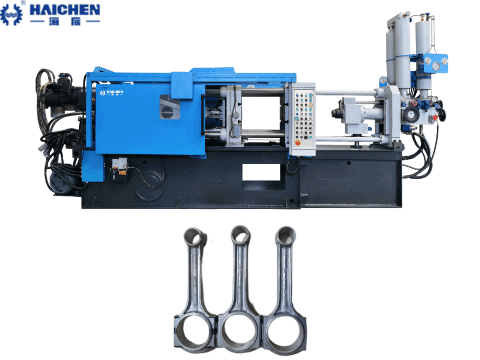

A connecting rod in die casting is a crucial mechanical component that links the piston to the crankshaft, ensuring smooth machine operation.

In the core injection system of a die casting machine, the connecting rod is the critical part that changes the piston’s linear motion into the crankshaft’s rotation.

Its design and build quality directly control the stability of injection speed and pressure. This finally affects casting quality and production efficiency.

This article explains the rod’s function, material needs, and how HAICHEN improves machine performance by optimizing this key part.

Definition of Connecting Rod

The connecting rod links the injection piston to the crankshaft. During injection, hydraulic oil pushes the piston in a straight line. The rod transfers this force to the crankshaft, turning it into the rotating force that drives the injection plunger forward. This efficient force conversion is the base for the machine’s high-pressure, high-speed injection.

Function of Connecting Rod

The primary function of the connecting rod is to transmit the force generated by the piston to the crankshaft. This transmission ensures precise control as it injects molten metal into the mold cavity. The connecting rod must be strong and durable to withstand the high – pressure and high – temperature conditions of the die casting process.

Material and Design

Manufacturers make connecting rods from high – strength steel or alloy materials to ensure durability and resistance to wear. The design of the connecting rod must be precise to ensure smooth operation and minimal friction. HAICHEN uses advanced materials and manufacturing techniques to produce connecting rods that meet the highest standards of quality and performance.

Importance of Connecting Rod

The connecting rod is essential for several reasons:

- Efficient Power Transmission: It ensures that the force generated by the piston is efficiently transmitted to the crankshaft, maintaining the machine’s operational efficiency.

- Durability: High – strength materials ensure that the connecting rod can withstand the harsh conditions of the die casting process, reducing the need for frequent replacements.

- Precision: Precise manufacturing ensures that the connecting rod operates smoothly, contributing to the overall precision of the die casting machine.

HAICHEN: Your Partner in Die Casting Excellence

At HAICHEN, we specialize in manufacturing high – quality die casting machines with reliable components, including connecting rods. Our machines are designed to provide precise control and efficient operation, ensuring that every part produced meets the highest standards. Whether you are starting a new project or upgrading your existing equipment, HAICHEN has the solutions to meet your needs.

HAICHEN in Practice: Ensuring Efficiency with Reliable Rods

HAICHEN sees the connecting rod as the “backbone” of the power system. Its reliability is key to stable, continuous production.

Case Study: Supporting High-Volume Auto Part Production

A die caster making transmission housings for global car brands needed machines to run non-stop with over 98% uptime. The long-term stability of the connecting rod was critical.

- HAICHEN Solution: For their 800-ton machine, we provided a reinforced connecting rod assembly. Besides premium materials and precise making, we improved the lubrication and cooling for the big-end bearing. This kept temperatures stable even at over 6 cycles per minute.

- Result: After two years of intense production, the rod assembly showed no abnormal wear or increased play. The pressure variation (Cv) at the end of injection stayed below 1.5%, ensuring very consistent part quality. The customer extended the rod’s preventive maintenance interval from 12 to 18 months, cutting maintenance cost and downtime risk.

Understanding the role of the connecting rod in die casting is crucial for achieving high – quality and efficient production. By choosing high – quality connecting rods and maintaining them properly, you can ensure consistent performance and long – term reliability.