Die casting cookware refers to kitchen utensils, such as pots, pans, and other cooking vessels, that are manufactured using the die casting process.

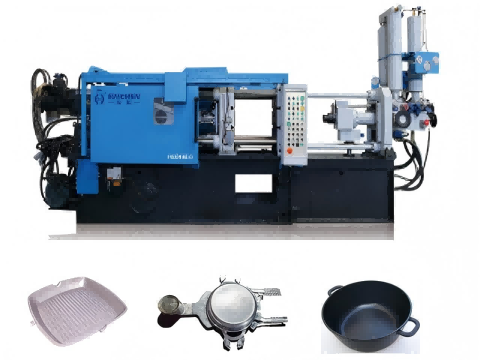

Cookware is using cold chamber die casting machine for production. Die casting is a manufacturing technique that involves forcing molten metal under high pressure into a mold cavity.

The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process.

Key Components of a Cookware Die Casting Machine

A specialized industrial machine manufactures cookware items, such as pots, pans, and lids, through the die casting process.

- Injection System

- Die (Mold)

- Clamping Unit

- Cooling System

- Ejection System

- Control System

Injection System

A furnace melts the metal (typically aluminum or aluminum alloys).

A plunger or piston injects the molten metal into the die at high pressure.

Die (Mold)

Machinists create the die as a two-part steel mold shaped to the form of the cookware item.

Design the mold with high pressure and temperature during the casting process.

Clamping Unit

Holds the two halves of the die together with significant force to prevent leakage of molten metal during injection.

Cooling System

Cools the molten metal rapidly to solidify it into the desired shape.

Ejection System

Once the metal solidifies, the die opens, and ejector pins push the finished cookware item out of the mold.

Control System

Modern die casting machines are equipped with computerized controls to manage temperature, pressure, injection speed, and cycle times for precision and consistency.

Die cast cookware advantages

Is cast aluminum cookware safe for using?

Obviously, besides being safe and reliable, die-cast aluminum alloy cookware has many other advantages, such as:

- Uniform Thickness

- Complex Shapes

- Durability

- Heat Conduction

- Surface Finish

Uniform Thickness: The die casting process allows for consistent wall thickness, which can lead to more even heat distribution and better cooking performance.

Complex Shapes

Intricate designs and patterns, including integrated handles, lids, and other features, can be created.

Durability

Die cast cookware is generally quite durable and resistant to wear and tear.

Heat Conduction

Metals like aluminum conduct heat efficiently, which is ideal for cooking.

Surface Finish:

Die cast items usually have a good surface finish and may require minimal machining or polishing after casting.

Haichen cookware supplier

Haichen is an aluminum cookware die-casting machine manufacturer, providing aluminum alloy product production lines for many international aluminum cookware manufacturers.

We have very rich experience in the field of metal die casting molding. And we mainly supply cold chamber and hot chamber die casting machine.Our cookware machine has a wide range of applications, stable operation, environmental protection and high production efficiency. We have more than 20 years of experience in the field, with well-trained workers, experienced engineers, and a service team to manufacture molding machines. We provide quality service to every customer around the world.