The die casting machine boosting cylinder is the key component in the die casting process to increase the pressure in the system.

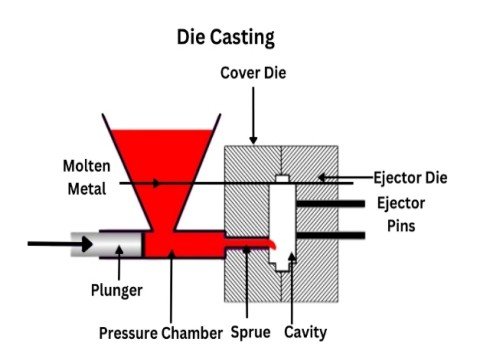

During the die casting process, the boosting stage ensures that the molten metal can be effectively injected into the mould cavity by increasing the pressure in the system.

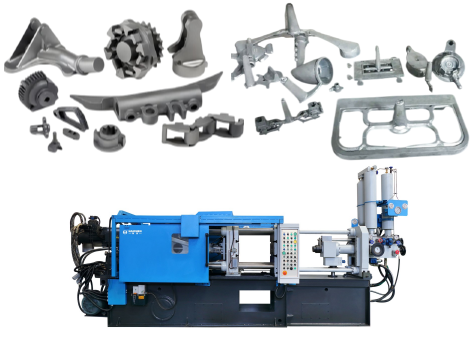

The design and application of die casting boosting cylinder can significantly improve the quality of die castings, increase production efficiency and reduce operating costs.

Specifically, the role of the booster cylinder is to ensure that the mould cavity is completely filled by increasing the pressure after the injection stage.

Thus achieving high precision part sizes and shapes.

This boosting mechanism also has different flow characteristics for thick- and thin-walled parts:

Thick-walled parts have a smaller boosted flow, while thin-walled parts have a larger boosted flow.

Therefore, the reasonable setting of booster time and pressure is to ensure the quality of die casting important factors.

Boosting cylinder also and die casting machine other key parameters such as mould clamping force, boost pressure ratio and so on closely related.

These parameters together determine the overall performance of the die casting machine.

By optimising the design of the booster cylinder and the control circuit.

This will solve a wide range of problems in the die casting process.

Improve labour productivity and reduce operating costs.

Booster cylinder plays a vital role in die casting machine.

It not only affects the filling effect of the mould, but also directly relates to the quality of the final product and production efficiency.

The workflow of the die casting boosting cylinder of the die-casting machine

The workflow of the pressurising cylinder of a die casting machine involves a number of steps.

Its core purpose is to pressurise the incompletely solidified metal through the pressurising cylinder after the liquid metal has filled the mould cavity.

In order to improve the denseness and surface quality of the casting.

The following is a detailed description of the pressurising cylinder workflow:

- Initial state

- Metal liquid filling stage

- Die casting boosting cylinder Start boosting

- Boosting process

- Pressure preservation stage

- End of pressurisation

Initial state

In the process of pressure injection, the hydraulic oil first enters the booster accumulator through the oil circuit, and then enters the booster cylinder through the control valve.

At this time, the booster cylinder is in a ready state, waiting to start the booster operation.

Metal liquid filling stage

As the press injection punch continues to advance, the metal liquid is rapidly injected into the mould cavity.

When the liquid metal is filled to a certain height, the alloy liquid begins to solidify.

And the booster cylinder has not yet been activated.

Die casting boosting cylinder Start boosting

When the alloy liquid starts to solidify, the start condition of the booster cylinder begin.

At this time, the high-pressure oil in the booster accumulator flows rapidly into the booster cylinder through the control valve, pushing the booster piston to move forward.

Boosting process

The pressurising piston pushes the pressurising piston rod to overcome the back pressure in the back pressure cylinder, so that the pressurising piston continues to move forward.

This process exerts pressure on the metal liquid which has not been completely solidified

Thus improving the denseness and surface quality of the castings.

Pressure preservation stage

After the pressurisation is complete, the booster cylinder will maintain a certain pressure to maintain the shape and density of the casting.

This stage is usually controlled by a computer system to ensure that the pressurisation time.

Pressure and other parameters are in accordance with the process requirements.

End of pressurisation

When the die casting machine boosting cylinder completes its role, the system will automatically close the booster valve to stop the booster operation and prepare for the next cycle.

The entire booster cylinder workflow is managed through precise hydraulic control and computer programmes.

This ensuring quality control of the casting during filling and solidification.

This pressurisation technology is particularly suitable for the production of metal castings requiring high precision and quality.

Where to install the booster cylinder of die casting machine?

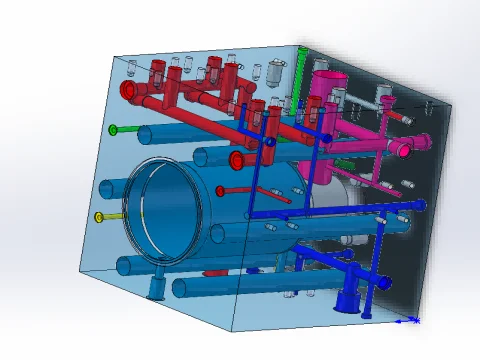

Booster cylinders for die casting machines are usually installed in the hydraulic system of the die casting machine, and the exact location can vary.

According to various different needs booster cylinders may be installed in the following positions:

- On the hydraulic cylinder and pipeline

- Fix die casting boosting cylinder Inside the mould

- On a fixed plate

- Booster cylinder body mounting table

On the hydraulic cylinder and pipeline

Booster cylinders are usually mounted on hydraulic cylinders and piping for easy venting.

And are usually mounted horizontally, but can be mounted vertically in special cases.

Fix die casting boosting cylinder Inside the mould

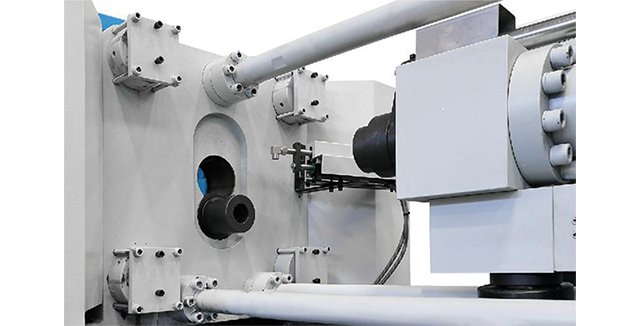

In some cases, the booster cylinder will be mounted directly inside the mould for localised pressurisation.

For example, in the manufacture of aluminium alloy die castings.

The booster cylinder may be mounted on the moving die insert inside the die.

A secondary pressurisation of the metal fluid is carried out by means of an extrusion rod connected to the piston rod of the booster cylinder.

On a fixed plate

In the centrifugal casting unit for motor rotors, the booster cylinder is fixed on the booster cylinder fixing plate.

Its output rod is connected to the pressurised rod slide plate.

Booster cylinder body mounting table

In the cold chamber die casting machine, the booster cylinder body mounting table is a rectangular mounting table.

Both ends extend to the opposite sides of the oil circuit board body and are of one-piece moulding structure with the oil circuit board body.

Therefore, the booster cylinder mounting position of the die casting machine may vary depending on the specific equipment and process requirements, but is usually associated with components such as the hydraulic system, the mould structure or the fixed plate.

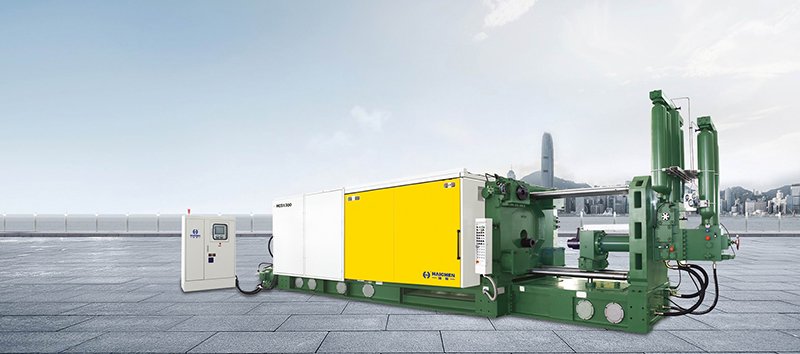

Haichen die casting machine high quality boosting cylinders

The advanced booster cylinder design of Haichen die casting machine is mainly reflected in its structure optimisation and function enhancement.

Haichen die casting machine adopts a variety of innovative designs to improve the booster capacity and die casting efficiency.

- Haichen die casting machine booster cylinder design adopts hydraulic cylinder sleeve structure

- Haichen die-casting machine also introduces the design of local booster mechanism

- Haichen die casting machine pressurisation system also combines a closed-loop control system

Haichen die casting machine booster cylinder design adopts hydraulic cylinder sleeve structure

By reasonably using the effective area ratio of A2 cavity and A1 cavity, the pressure borne by the piston rod is increased, so as to realise significant pressure boosting effect.

This design makes it possible to increase the pressurisation factor by more than 5 times under the same hydraulic system pressure.

Dramatically improve the pressure injection capacity, and shorten the booster time, effectively reduce the casting defects.

Haichen die-casting machine also introduces the design of local booster mechanism

A pressurising cylinder is set up on the mould to provide secondary pressurisation at the local wall thickness hot joints, so as to eliminate casting defects such as shrinkage holes.

This design not only improves the quality of castings, but also reduces the difficulty of mould processing and production costs.

Haichen die casting machine pressurisation system also combines a closed-loop control system

Through the booster accumulator, hydraulic oil source, pressure injection cylinder, valve and programmable logic controller work together.

The stable control of casting pressure is realised.

This closed-loop control system can effectively avoid the pressure instability and mould wear problems commonly found in traditional open-loop booster control.

Haichen die casting machine advanced booster cylinder design through the optimisation of the hydraulic cylinder structure, the introduction of local booster mechanism and the use of closed-loop control system.

Significantly improve the boosting capacity and production efficiency, while reducing the defect rate of castings, for the production of high-quality alloy die castings to provide a strong guarantee.