Die casting post process includes cleaning and deburring, heat treatment, machining and surface treatment these main steps.

The die casting post process is a series of operations done after a part leaves the mold. These operations make the part meet its size, look, or performance needs. This article will explain the main types of die casting post process steps, how they affect final product quality, and how to help optimize this flow through better casting control.

Die casting post-processing refers to a series of processing and treatment steps performed on castings. After the die casting process completed to improve their performance, appearance and functionality. These steps usually include the following aspects:

- Main Types of Die Casting Post Process Steps

- How Die Casting Post Process Links to Casting Quality

- HAICHEN Practice: Reducing Post-Process Challenges with Better Casting

What is die casting post process?

The die casting post process includes all follow-up work on a casting after it forms in the die, like cleaning, machining, and surface treatment. This article will first list the key steps in the die casting post process. Then it will link post-process quality to the casting process. Finally, a HAICHEN case will show how to reduce post-process work by improving the casting step.

Main Types of Die Casting Post Process Steps

- Cleaning and Deburring

- Precision Machining

- Surface Treatment and Strengthening

- A full die casting post process usually has three kinds of operations

Cleaning and Deburring

This step removes the biscuit, overflows, and vents. It also removes flash and burrs from parting lines and ejector pins to get a clean rough part.

Precision Machining

For parts needing high accuracy, machining like CNC, drilling, or tapping is a key die casting post process. This ensures the part meets the drawing’s size and tolerance rules.

Surface Treatment and Strengthening

To meet needs for look, corrosion resistance, wear resistance, or special function, common die casting post process steps include shot blasting, polishing, plating, painting, anodizing, or heat treatment.

How Die Casting Post Process Links to Casting Quality

- Rough Part Quality Sets the Difficulty

- Dimensional Accuracy Affects Machining Allowance

- Surface Condition Impacts Finish Results

- Testing and quality control

- Special treatment

The need for and cost of die casting post process depend directly on the quality of the casting step.

Rough Part Quality Sets the Difficulty

The amount of flash and internal defects from casting adds to cleaning and rework time. This affects post-process efficiency.

Dimensional Accuracy Affects Machining Allowance

Better size stability of the cast part allows for smaller machining allowances. This saves machining time, tool wear, and material waste.

Surface Condition Impacts Finish Results

Surface flaws on the cast part can hurt the look and coating bond of later plating or painting. This can cause post-process failure.

Surface treatment

In order to enhance the surface quality of the casting or give it a specific function, surface coating, plating or painting may be performed. These treatments can improve the corrosion resistance, wear resistance or aesthetics of the casting.

Testing and quality control

Post-processing of die casting also includes various tests on the finished product. Such as dimensional measurement, non-destructive testing (such as ultrasonic testing, magnetic particle testing), and appearance inspection to ensure that the product meets the design specifications and quality standards.

Special treatment

Depending on the application requirements, some castings may also require special post-treatment, such as anodizing (for aluminum alloy castings) to improve their corrosion resistance and decorative effect.

Therefore, die casting post-processing is an important part to ensure that die castings achieve the expected performance and quality. It involves a variety of processes and technologies to optimize the overall performance and service life of the product.

HAICHEN Practice: Reducing Post-Process Challenges with Better Casting

HAICHEN works to provide stable die casting machines and process know-how. This helps reduce post-process pressure and cost from the start.

A Customer’s Post-Process Problem

A maker of aluminum auto parts found fast tool wear during machining. Some areas also showed pores after cutting, causing high scrap and extra repair cost.

HAICHEN’s Root Cause Analysis and Solution

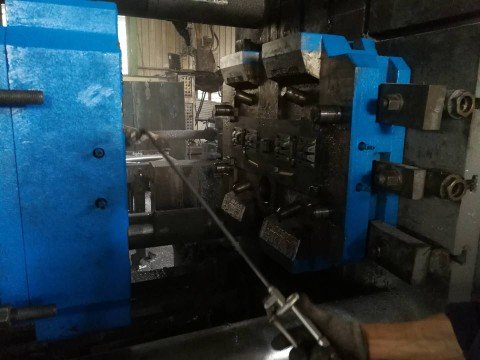

HAICHEN engineers found the root cause: unstable metal filling and poor venting during casting. The solution was to use a HAICHEN machine with high dynamic response and to optimize the gating and shot profile.

How Casting Improvement Affected Post Process

The new process greatly improved the part’s internal density and surface. Rough parts had less flash and more consistent size.

Overall Benefits for the Customer

Machining tool life grew by 30% on average. The defect rate for exposed pores after machining fell by over 80%. Overall post-process efficiency rose, and production cost went down clearly.

The die casting post process is a necessary step to make castings meet final use needs. Its complexity and cost are not separate. They link closely to the quality of the cast rough part. Choosing precise and stable die casting equipment and support, like from HAICHEN, leads to better rough parts from the start. This simplifies the die casting post process, lowers total cost, and boosts product competitiveness.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine.They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts. If you have any demand, feel free to contact us.