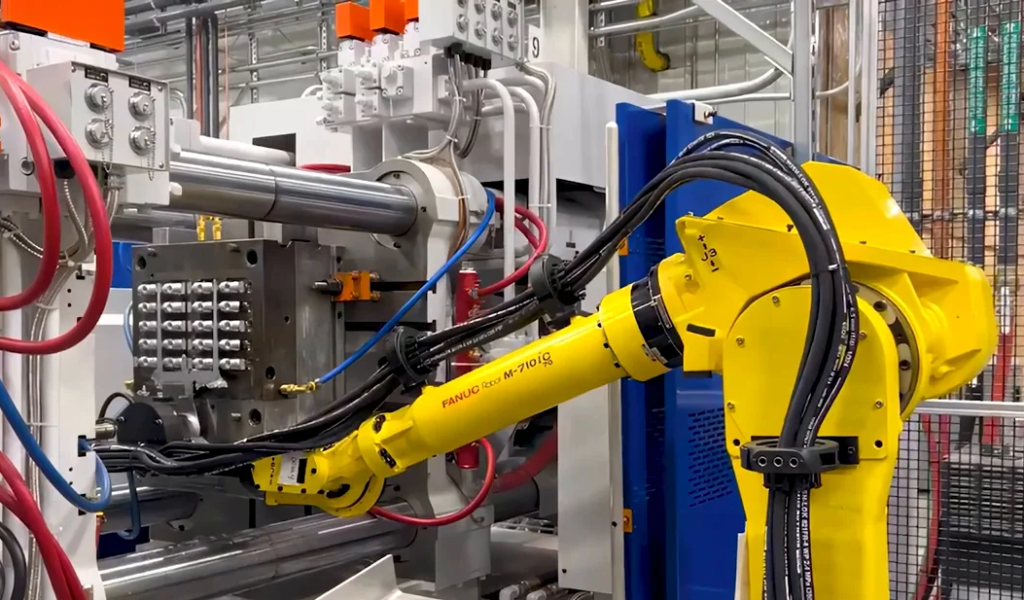

The uses of industrial robots in die casting machines include automating tasks like part removal, trimming, and inspection.

Under the splash of 800℃ molten aluminum and the impact of 15Bar mold closing, the die-casting workshop is one of the most demanding environments in the industrial field. Industrial robots have become rigid demands with three capabilities:

- Tolerance to extreme high temperatures: continuous exposure to 200℃ mold heat radiation;

- Millimeter-level repeatability: the position error of the pick-up is ≤±0.1mm;

- Zero-error safe operation: replacing manual labor to avoid burns and pneumoconiosis.

Integrating industrial robots into die-casting machines can improve automation, efficiency and productivity.

Uses of industrial robots in die casting

Industrial robots in die casting machines are employed at various stages of the production process, streamlining operations and enhancing productivity.

Material Handling

Tasks such as the loading of raw materials and the transfer of finished goods can now be performed by robots. These automated processes decrease operational errors and keep the production pace steady which aids in maintaining output efficiency.

Mold Management

Industrial molds are every experienced operator’s headache because they are often difficult to handle meticulously and need precision to avoid damaging the mold component. But with industrial robots on production lines, these skilled workers have a reliable assistant with them since industrial robots can automatically carry out mold assembly and disassembly tasks with great accuracy. With such automated operations, not only is process stability enhanced but die casting accuracy is improved which enhances mold quality at various levels.

Cooling and Ejection

The injected metal requires some time to cool before it completely solidifies. Using program commands, industrial robots are able to execute precise timing controls over a cooling cycle so that automatic ejection can occur optimally within preset boundaries. Because workpiece retrieval is done during optimal timings only, deformation flaws due to too-early removal won’t occur, thus preserving product quality consistency throughout production cycles.

Quality Control

While monitoring quality on the die-casting production line, a robot equipped with precision sensors and visual systems performs like an inspector. To some extent, they can assess the dimensions of castings during the die casting cycle and capture surface pores or cold shut lines through imaging systems. This type of monitoring is akin to outfitting the production line with “fire eyes and golden eyes” because workers observe real-time data feedback on control screens. The system is capable of raising alarms for momentary discrepancies after performing calculations in real-time precision which allows operators to make instant parameter adjustments avoiding batch scrapping.

Post-Processing

The casting processes usually require extra steps such as trimming, grinding, and polishing. With industrial robots capable of taking over these functions it resolves issues with consistency and saves on manpower investment. Such automation not only increases productivity but also enhances the quality triad—product consistency and overall excellence are significantly improved too.

Application scenarios and economic benefits

Case analysis: Auto parts die casting

| Indicators | manual operation | Haichen robot solution |

| Single piece production cycle | 110 seconds | 68 seconds |

| Shift output | 320 pieces | 520 pieces |

| Defective product rate | 5.20% | 0.80% |

Robot Selection Guide

| Key Requirements | Recommended Models | Travel | Type |

| Small Precision Parts | KA550 | 550mm | Single Stage |

| Medium Auto Parts | KAS-1200P | 1200mm | Dual Axis |

| Ultra-Large Structural Parts | KAW-1800P | 1800mm | Triple Axis |

The uses of industrial robots in die casting machines is a testament to the advancement of automation technology.

They play a key role in achieving higher levels of efficiency, precision, and safety in the die casting industry.